Okay, so. Today’s update is a bit different, because technically it’s post three of four, and I did photograph and edit most of pics for this post before I worked on post four. But as this lock needed cleaning, and I left it to soak in GUNK overnight, I did a momentary pause on this post and then photographed and wrote up the next post first. So if the way that next post is written oddly (such as me covering some topics twice, or whatever), you know why. It was written first and posted last.

Anyway, enough of this poppycock. We’ve got locks to investigate!

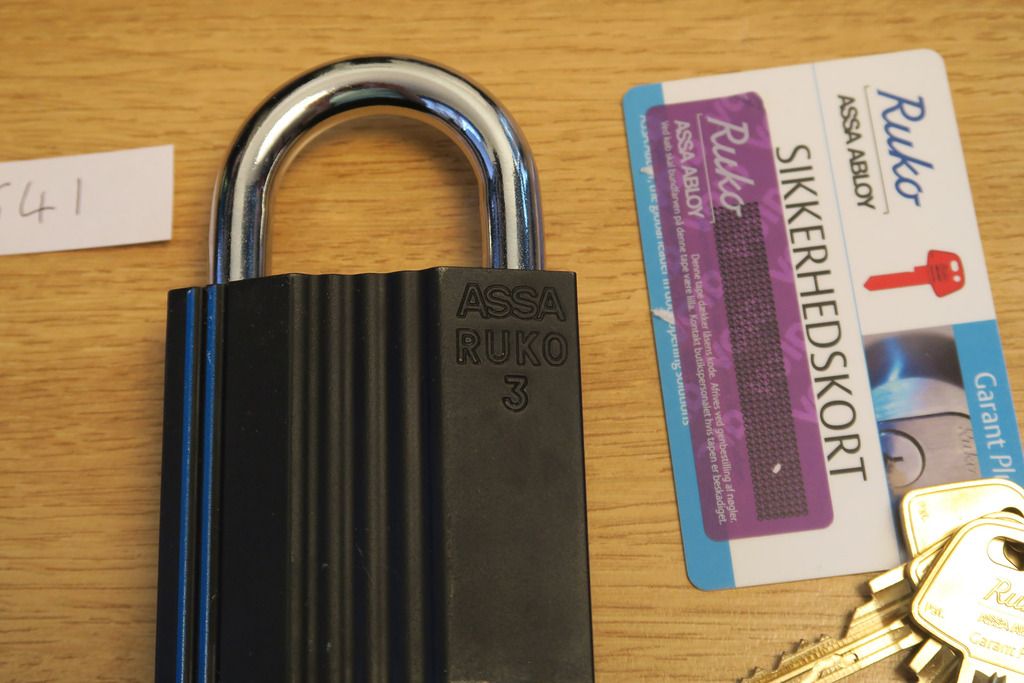

Dayum – you have no idea how happy I am to get this lock. Despite all these updates coming more-or-less “at once” for you guys, I’ve had the 833s and 951 for a while now, but the 826 has been on my hit-list for ages. I’m still short a certain 826C.... But we’ll get there

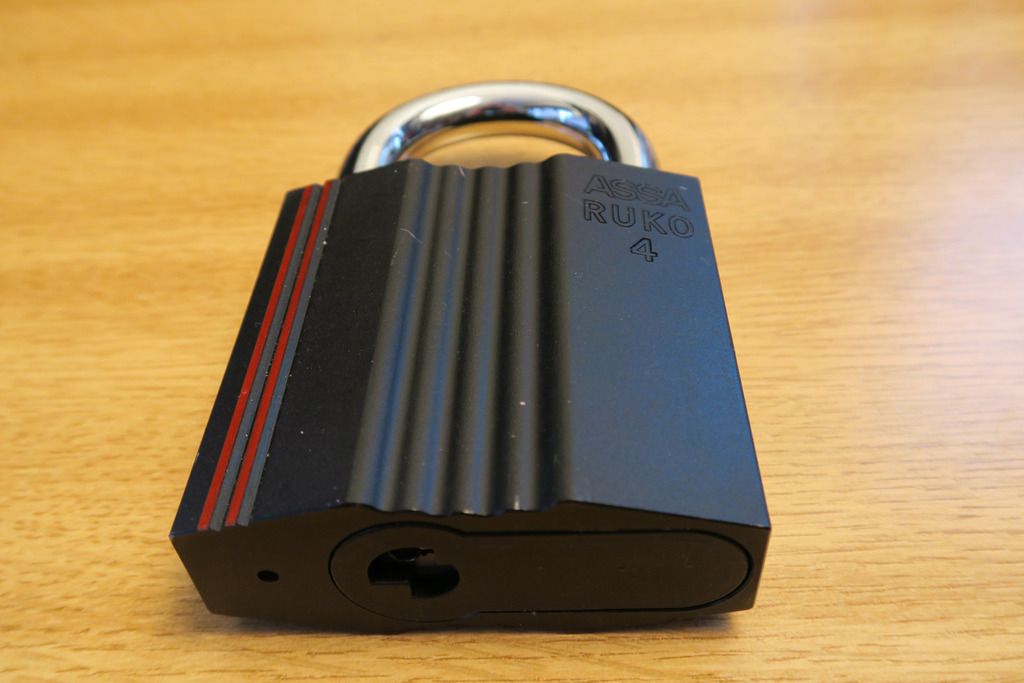

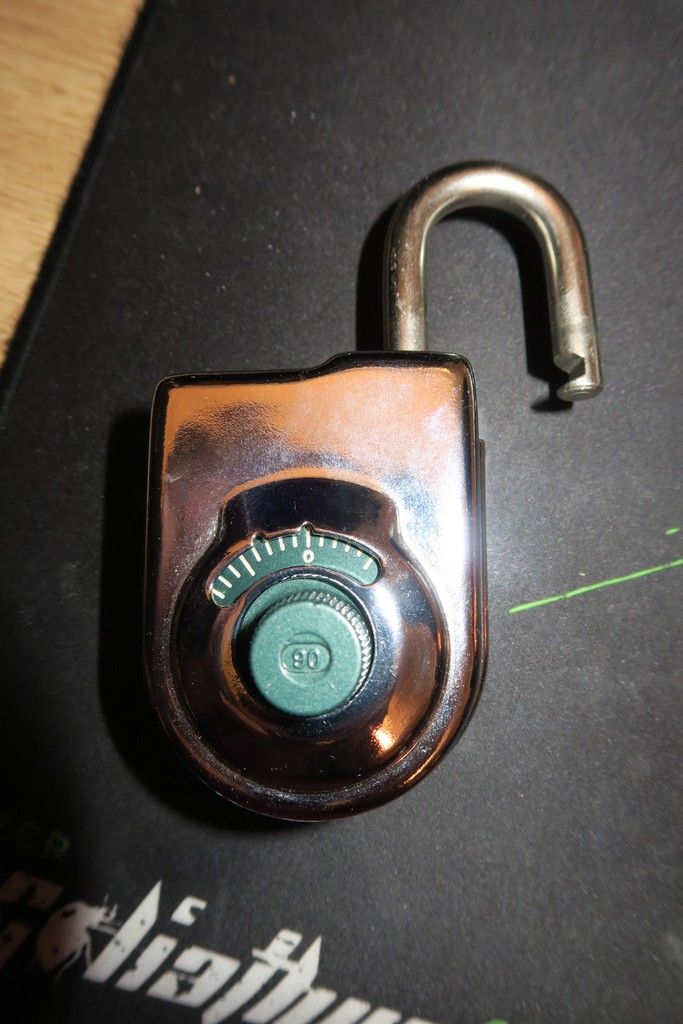

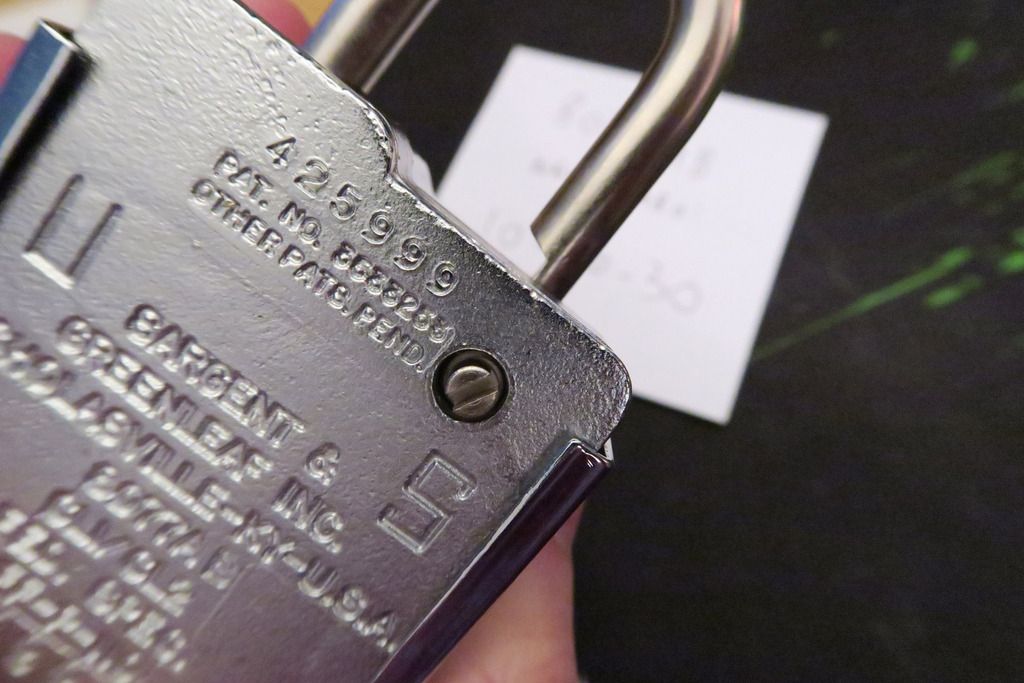

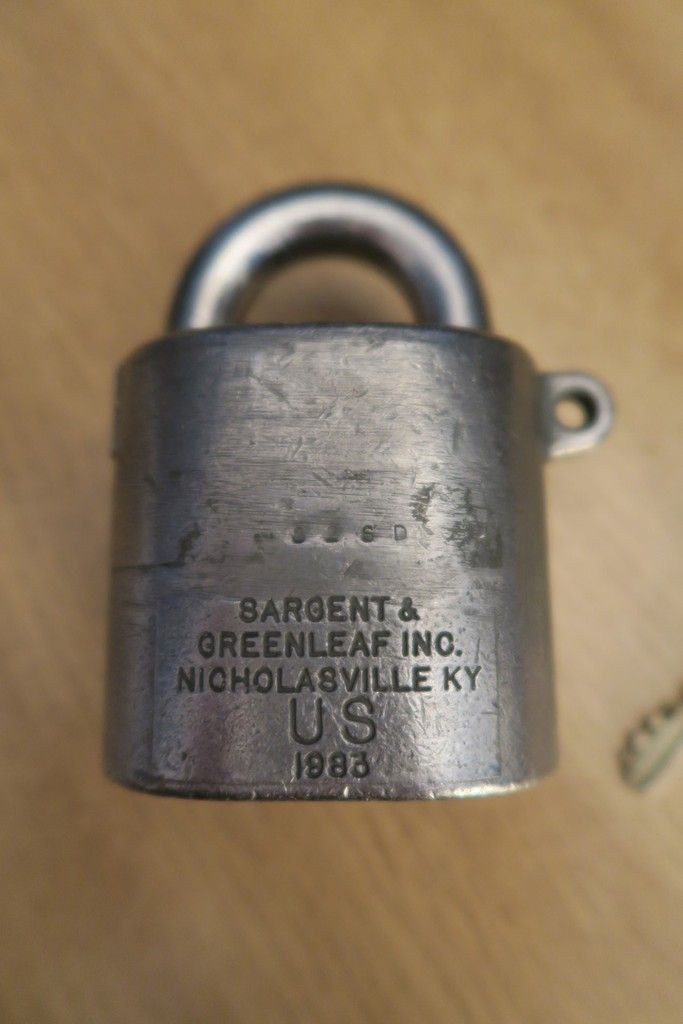

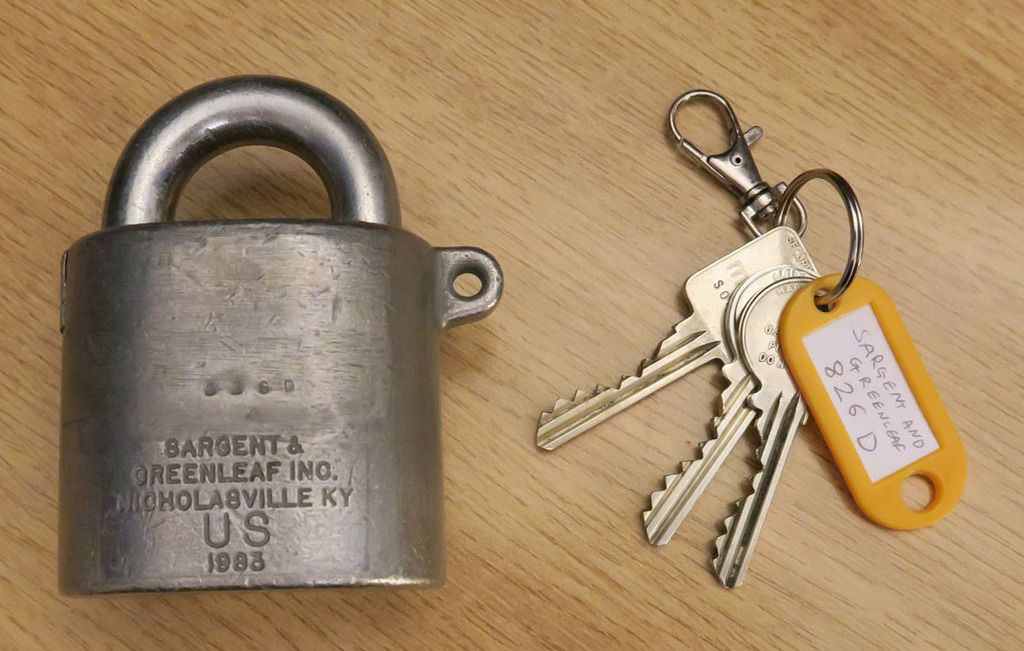

. What you’re looking at right now is a Sargent & Greenleaf 826D, and it is awesome.

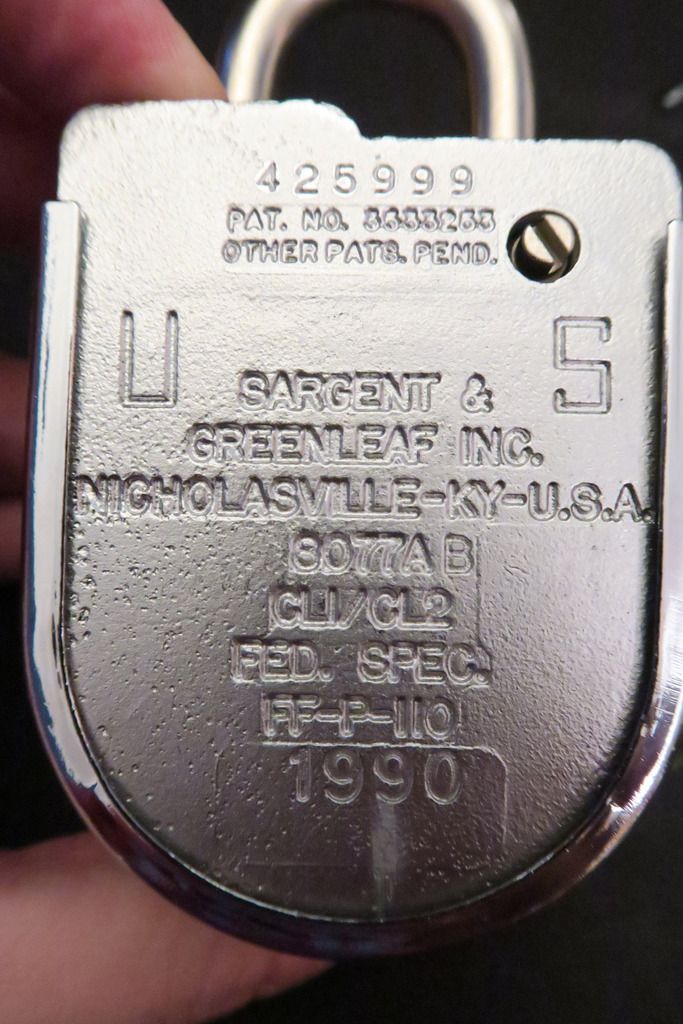

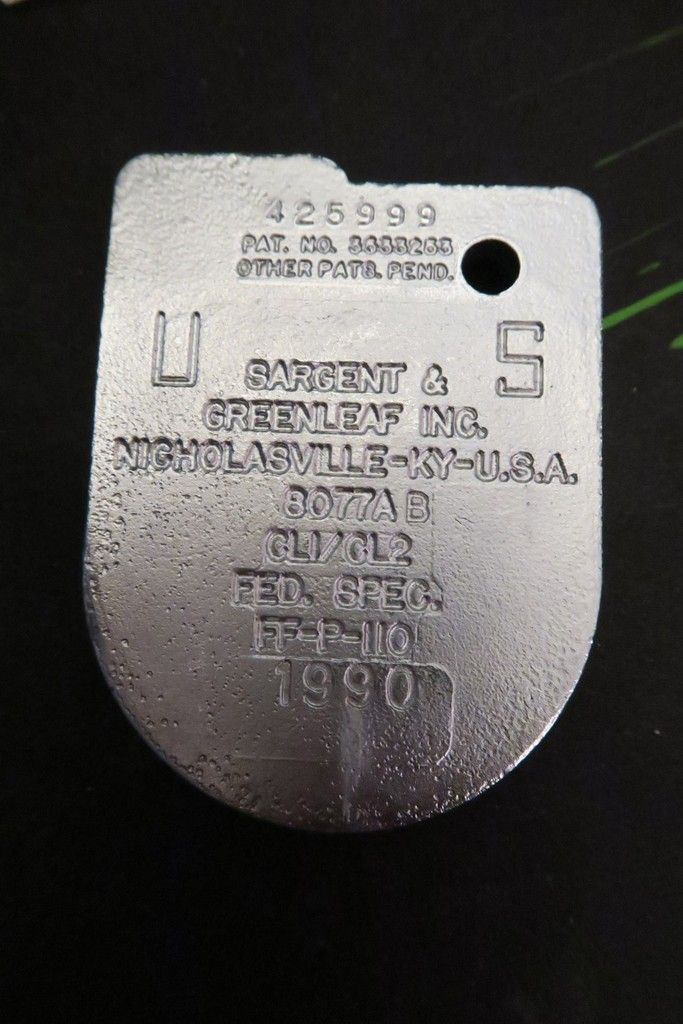

The 826D is characterised by a thicker shackle and a thicker/heavier body – The 826A is “the rare one”, I believe with a thinner shackle as standard, and the 826C has the thick shackle of the ‘D’ but the thinner body of the ‘A’. I’ve not seen an 826B, but I’m sure it must exist somewhere. The A and C variants usually have the model number stamped clearly onto them, whereas the D does not – although mine does have it stamped on very lightly – but being the only one with a thicker body, that doesn’t matter as much for identification purposes.

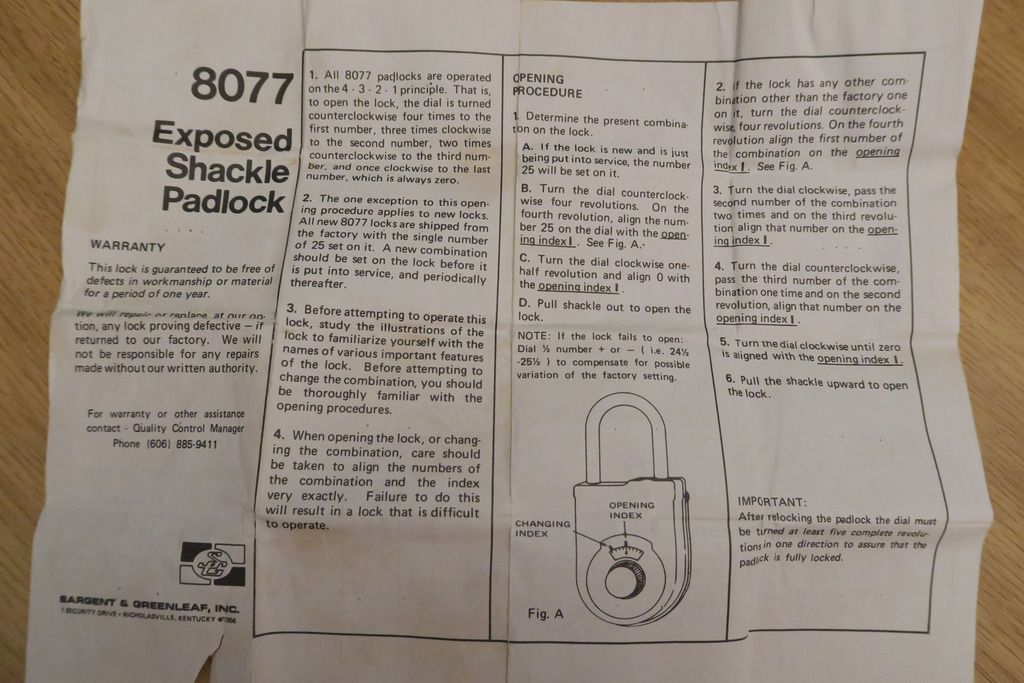

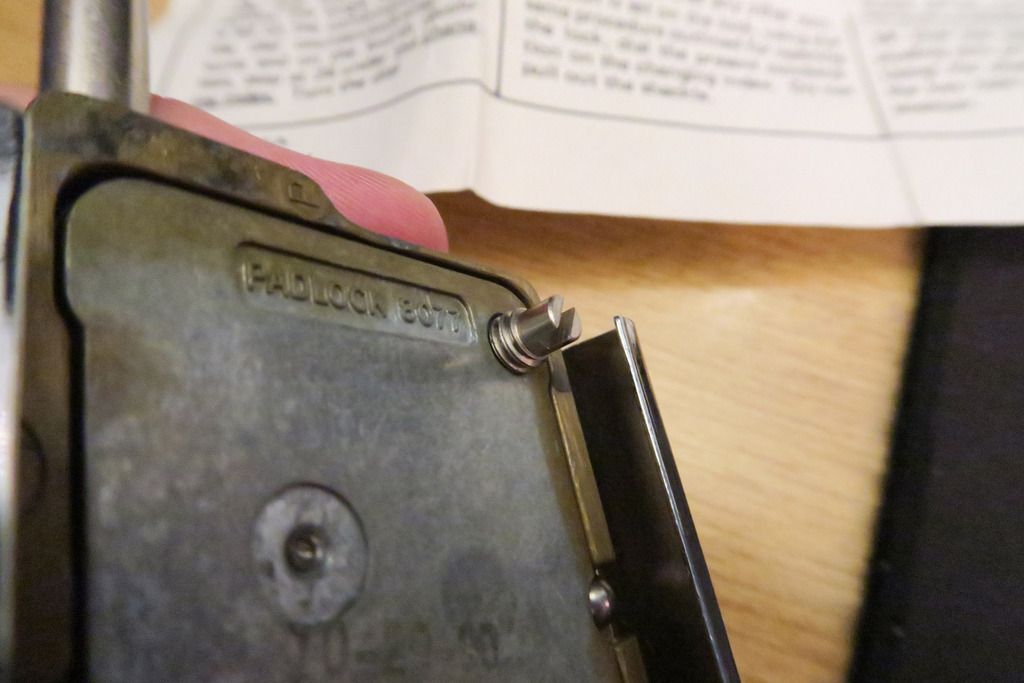

At the same time as Sargent and Greenleaf have developed their top-tier super-strong and incredibly-heavy closed-shackle lock series – the 831, 833, and 951 – there has always been a call for middle-range S&G locks – stronger than the 8088 and 8077 series (which are pretty much fancy security seals) – and of course key operated, but also able to be locked to chains and hasps where the heavy-duty NAPEC hasps aren’t called for, or where an open shackle, non-restrictive lock are needed.

The 826 series are the padlocks that filled that niche. They still have that heavy-duty appearance and “blast-proof” claim of the bigger siblings, but I believe they aren’t rated for liquid nitrogen attacks and of course have that exposed shackle.

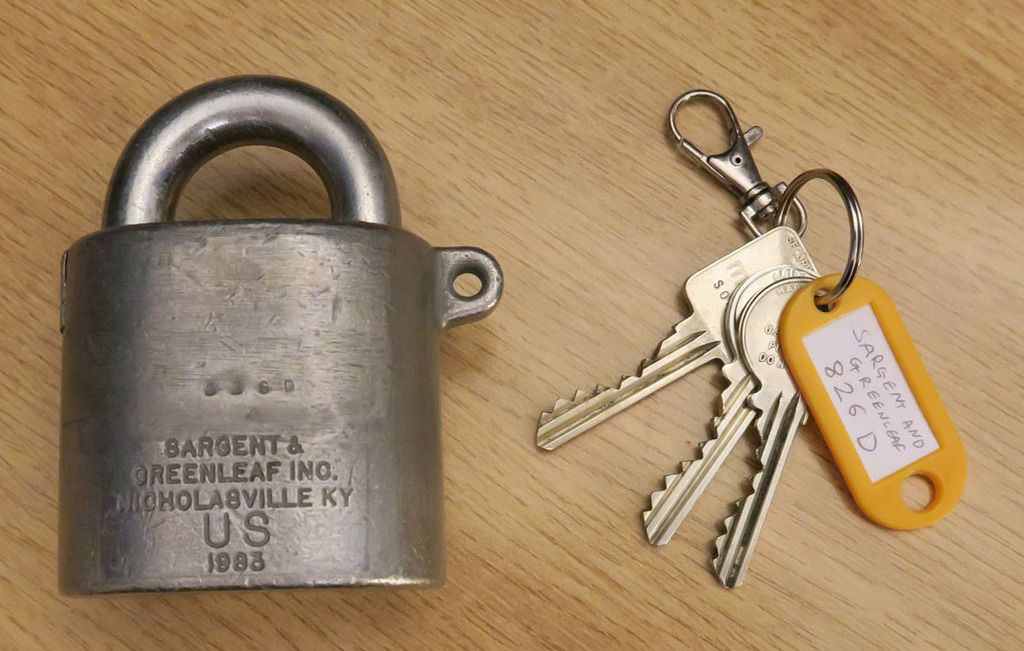

In the photo about you can see the lock as it came to me – with three keys (two operator and one control), two keyrings and the lock itself. The body looks to be in decent condition considering the age of these, and operates nicely

.

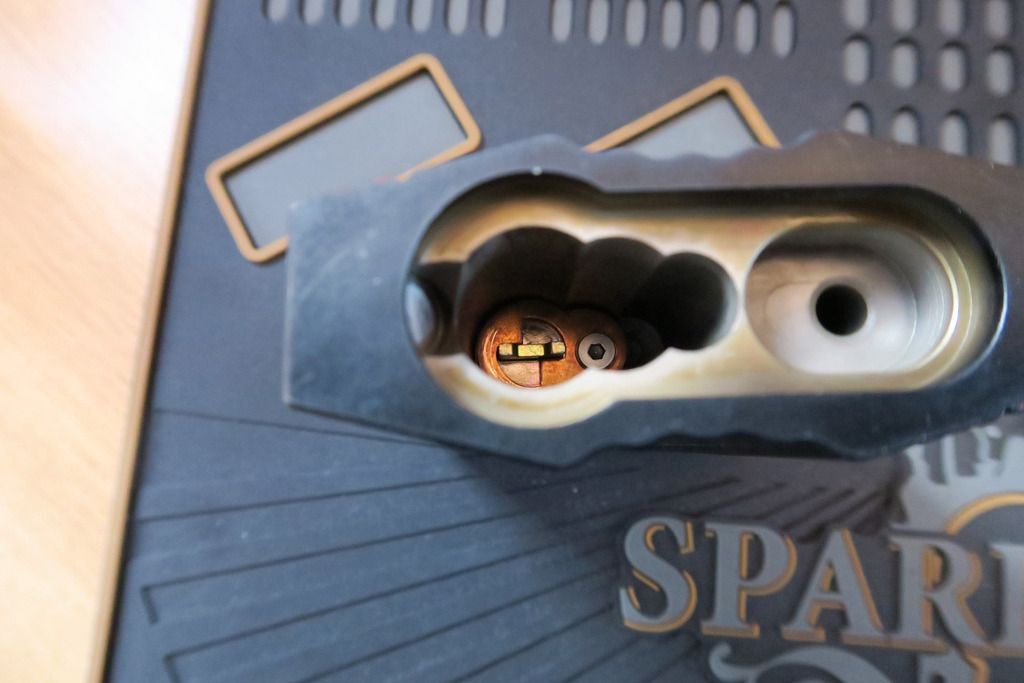

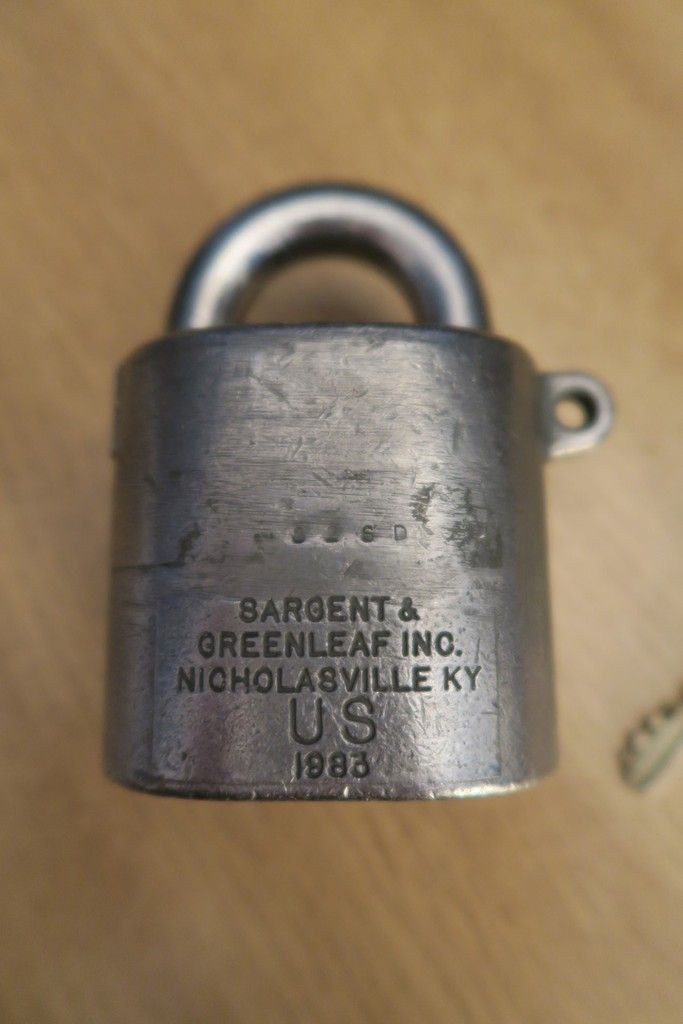

Closeup of the front of the body:

1983 – it’s older than I am! Above the properly stamped in logo info, you can see the “826D” designation very lightly stamped in, and deformed through use. I assume that this was done after the lock’s production, as I’ve also seen these without a model number stamp at all.

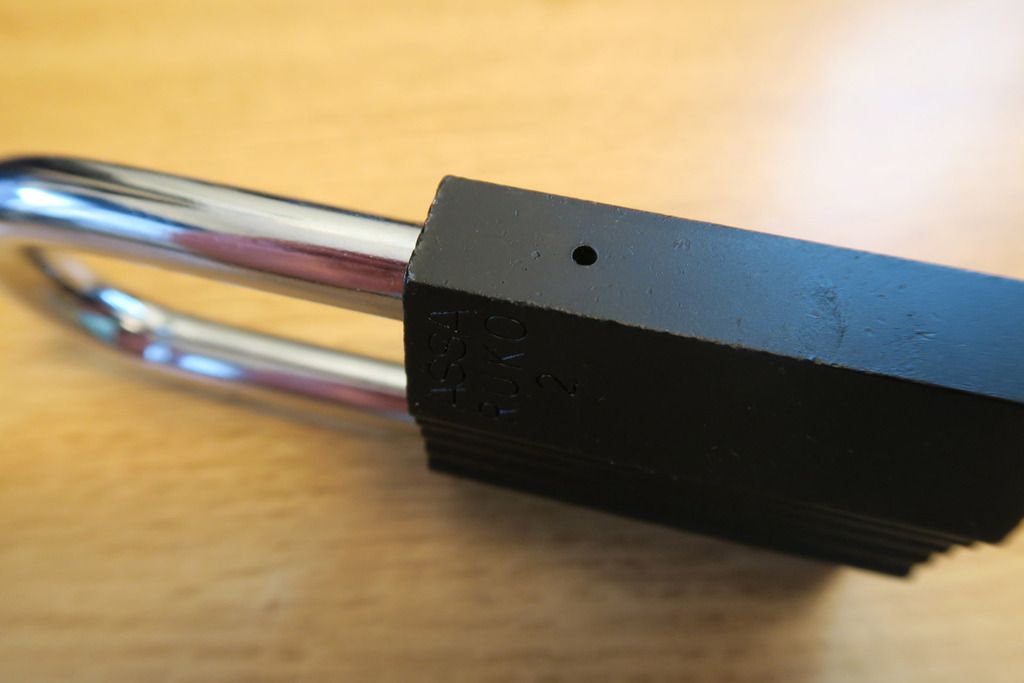

Side of the lock with the chain attachment and drain hole:

The other side – the cutout at the top is the disassembly plate:

View from the top - you can see the full extent of that plate here, starting at the right hand edge of the lock, encompassing the “open” shackle end and extending almost to the other shackle. That plate is removable, and is the method by which this lock can be disassembled:

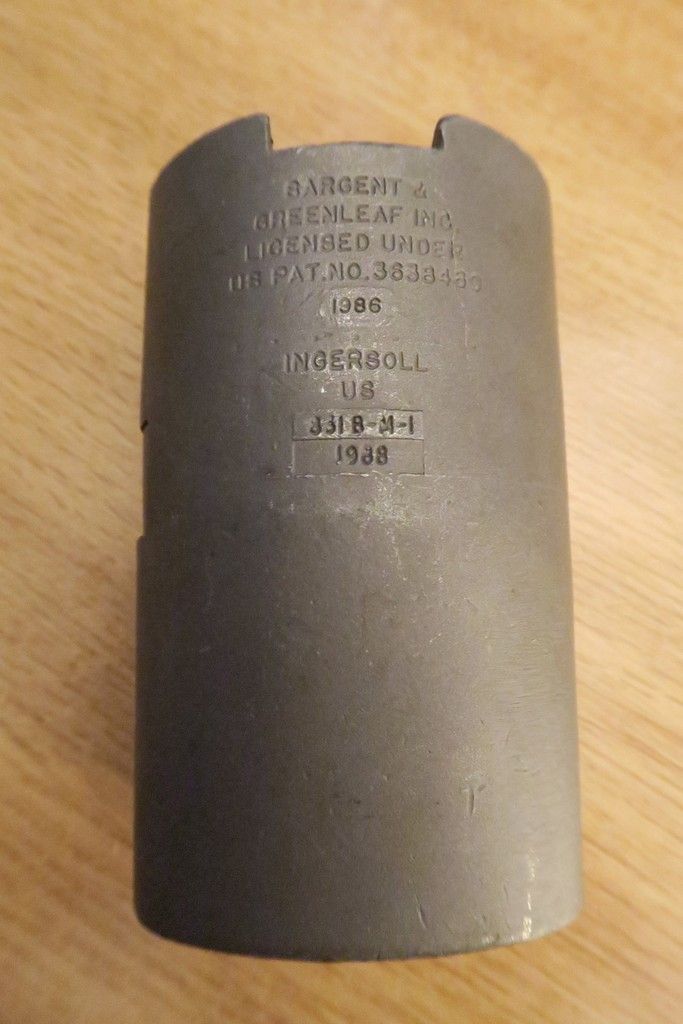

Plate from the side:

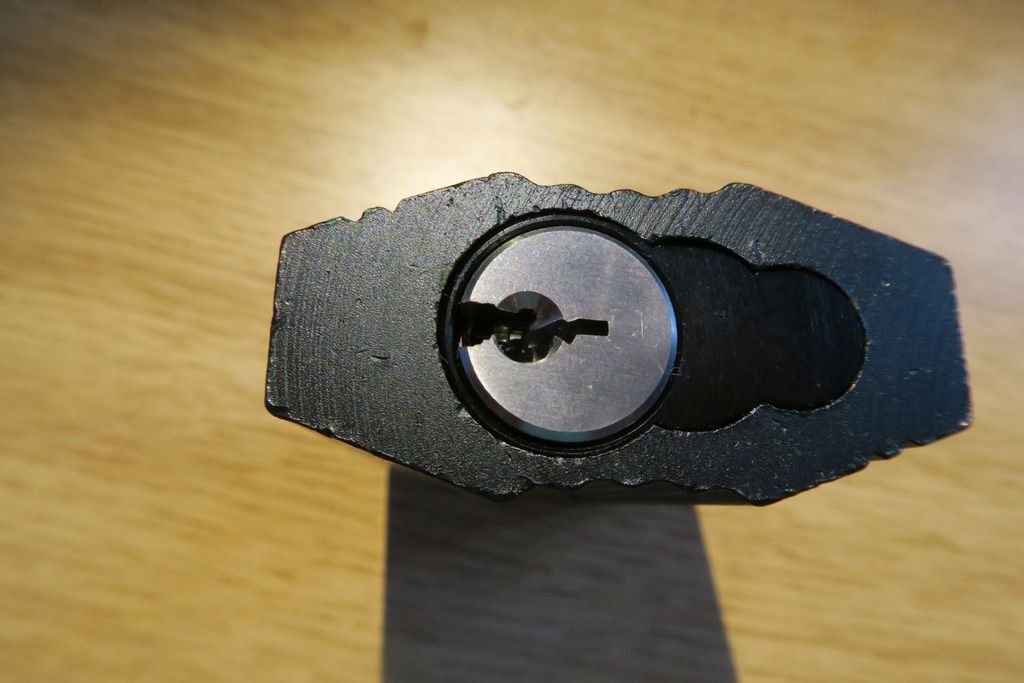

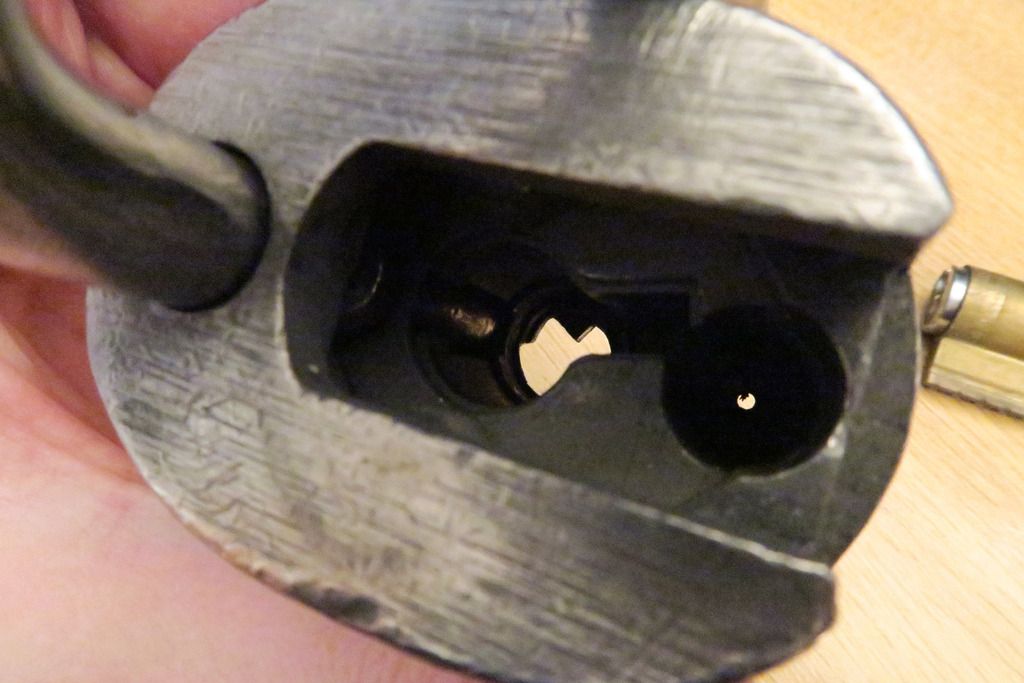

Bottom of the lock. The keyway cutout in the body bears resemblance with the 831 – specifically it’s shape, and lack of rotating anti-drill disk:

There are some odd numbers engraved and crossed out in this lock – I have no idea what that’s about. “10” “18” and “1”. Some kind of UID or inventory number maybe – not sure why they got crossed out though:

The keys:

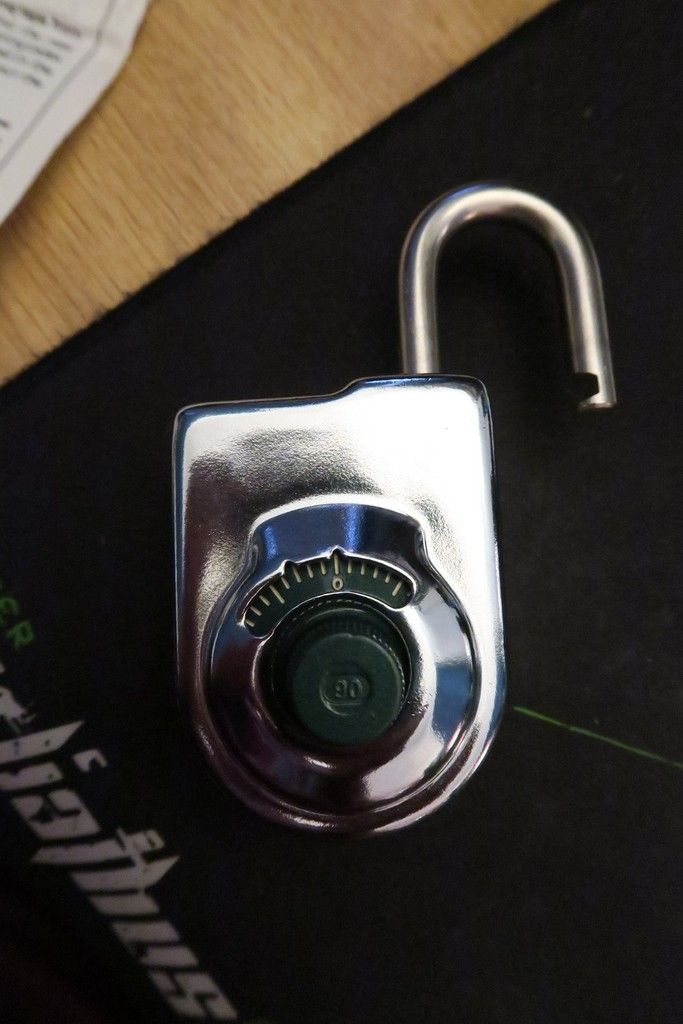

Padlock unlocked with the operator’s key:

What a beast!

Even with the shackle removed, this plate will not slide out in the “normal” open position:

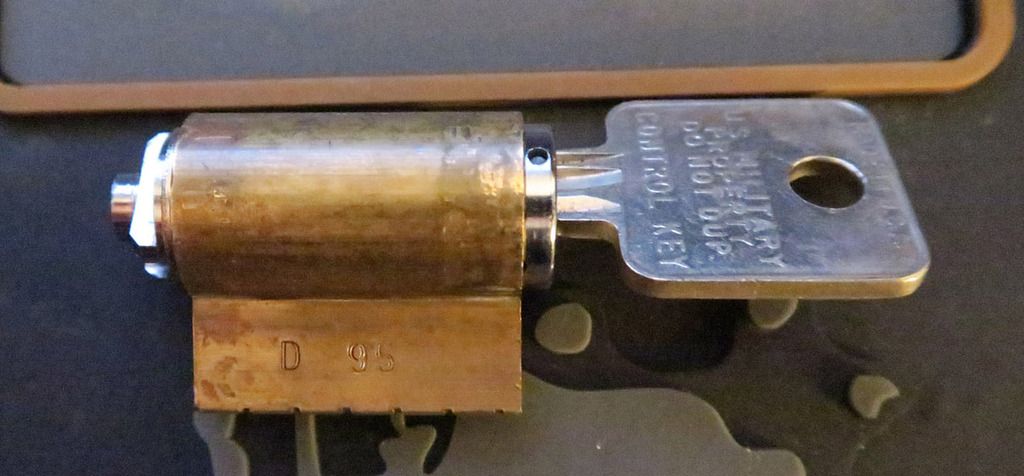

This lock works in the same way as all the other S&Gs – you need to use a control key, which is missing a key shoulder, and can rotate counter-clockwise to both unlock the lock and remove a blocking element:

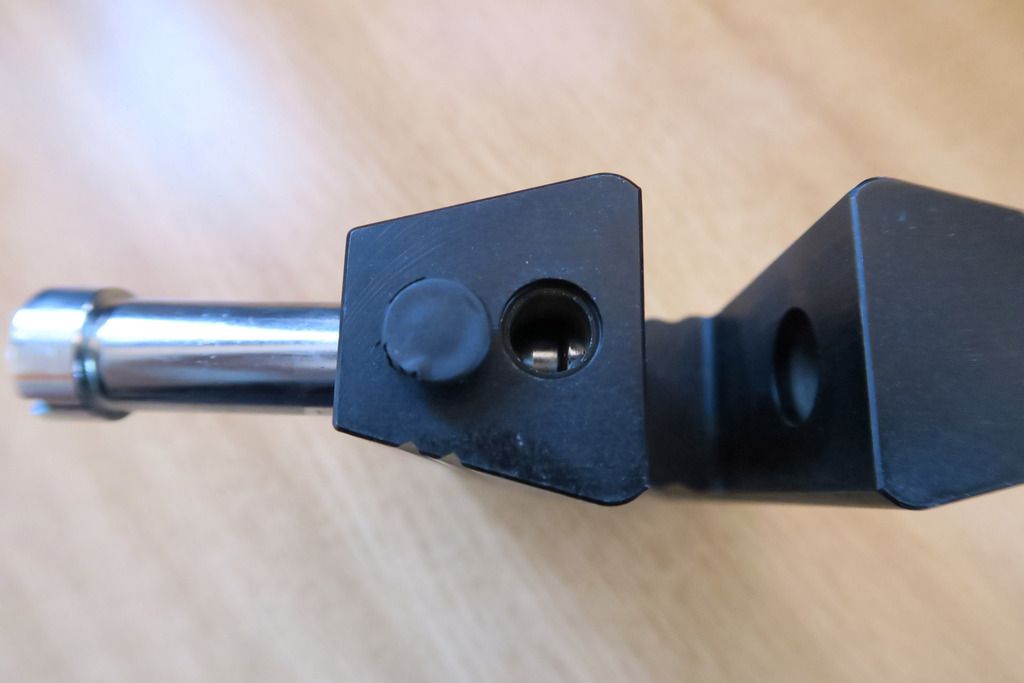

With the actuator set in a specific position, the plate will simply slide out sideways along a track (fun fact: the 826 locks are very simple and, apart from the cylinder and cover plate, only have one element which acts as both the actuator and locking pole – we’ll get to that):

That’s one chunky plate!

The bottom is stamped with the number “2” (I assume, like the 80** series of combination locks, this acts as a deterrent to destroying the lock and replacing it with an identically-pinned duplicate). There’s also an odd groove cutout on the left hand side – that’s where a nub in the actuator fits, to ensure that this plate can only slide out when the key is in the control position. In both the locked and unlocked (normal) position, the nub will slide to various points along the closed-off edge. Only when in the control position will the nub be positioned adjacent to the open cutout in the side of the plate:

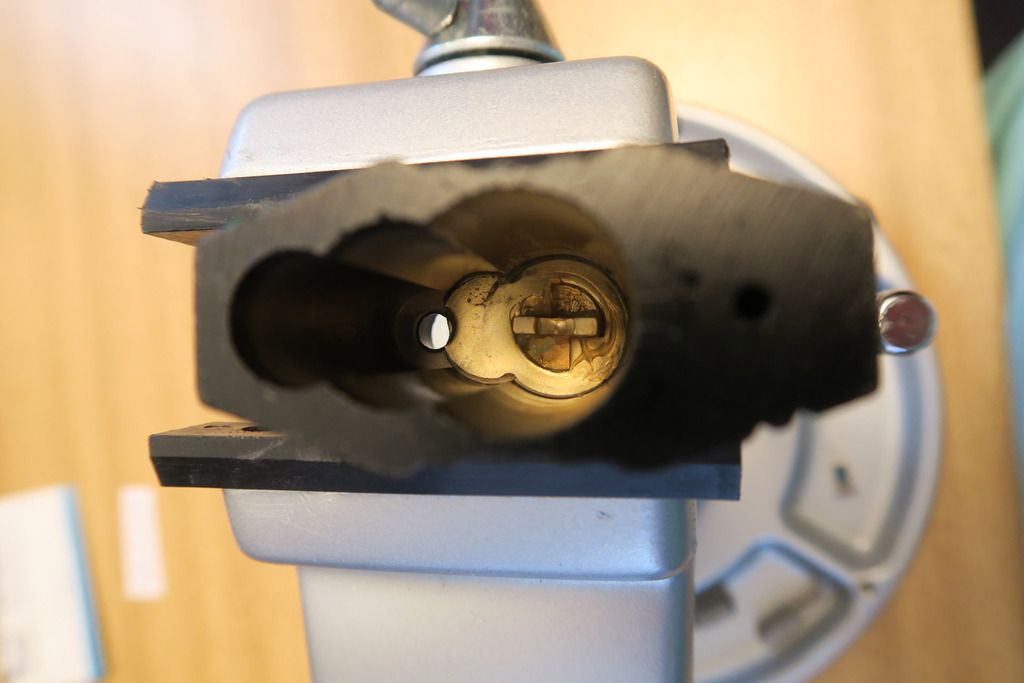

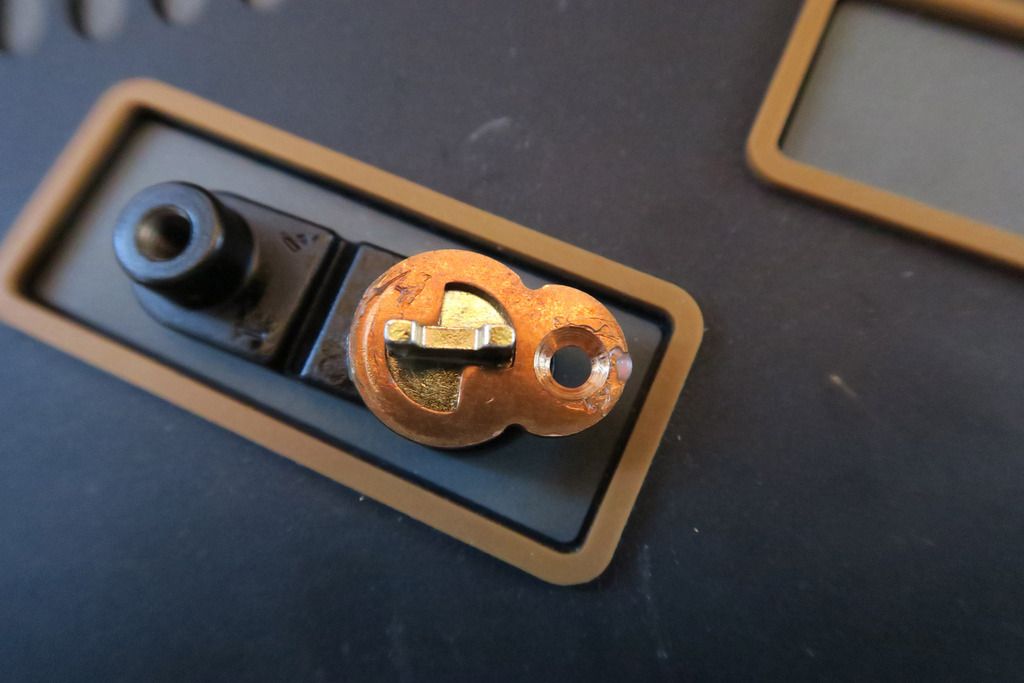

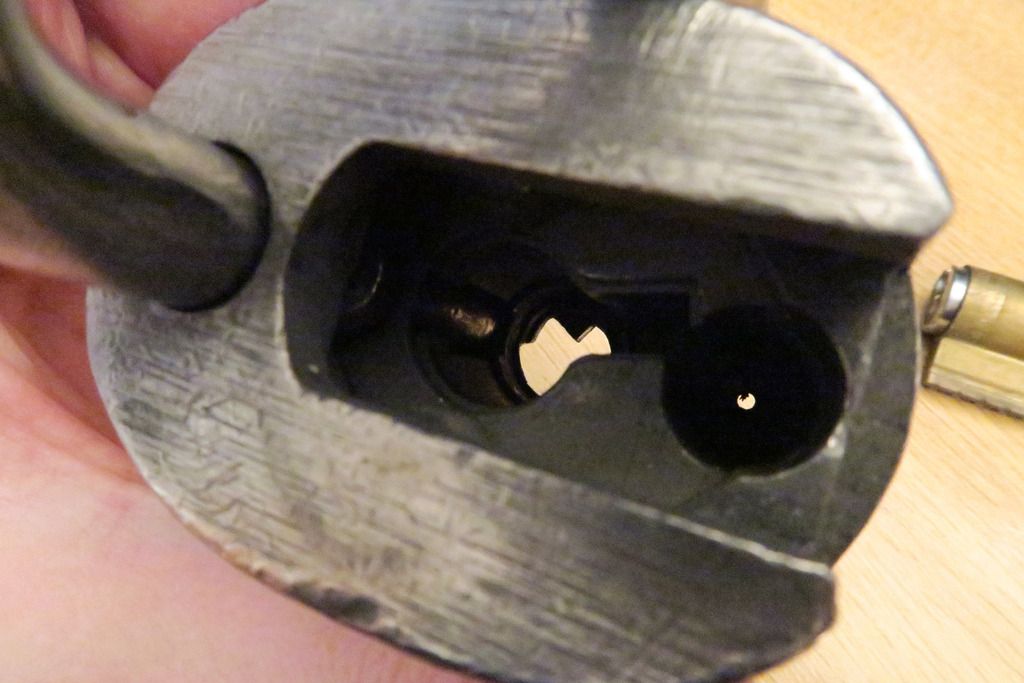

With the top plate removed, you can see the actuator inside. The little nub sticking out the top of the back of the round portion of the bar in the middle is the nub I was talking about which interacts with the top plate to keep the lock from being disassembled:

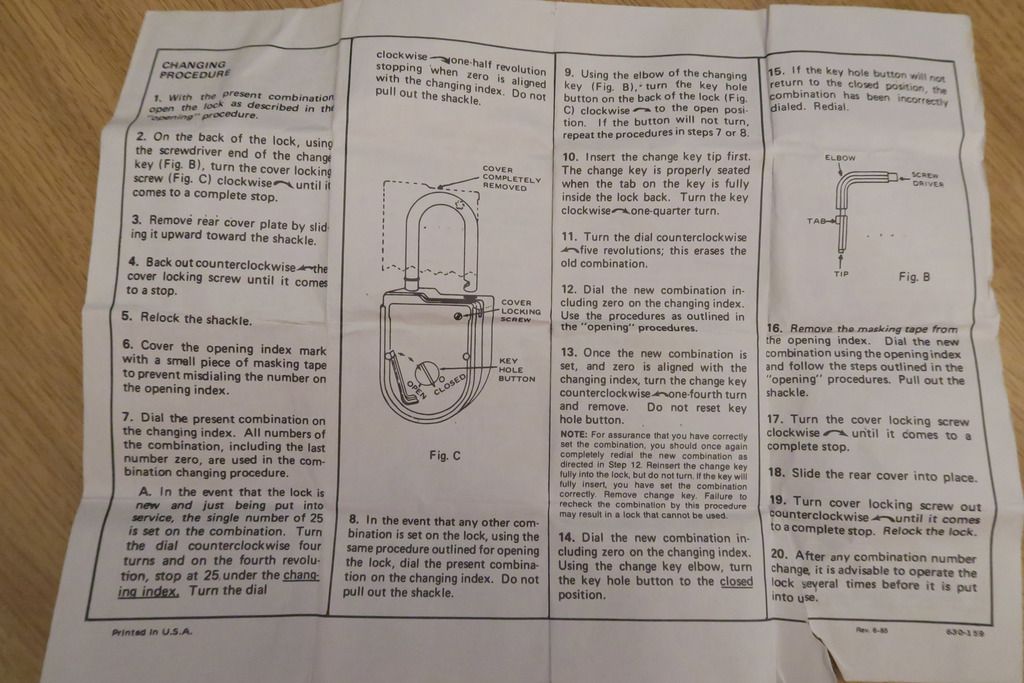

There’s a quite specific and fiddly method to opening these locks, and I actually spent ages fiddling around with it before giving up and checking the instructions, which luckily came with this lock. The complexity and fiddlyness of disassembly is likely one of the reasons that S&G changed to using a split-body design in their new, large locks (I’ve not come across anything like a modern equivalent to the 826 – I assume that in this day and age everything is simply locked with integrated cylinders, or electronic control doodads, so there is no call for padlocks anymore).

To easily disassemble these 826 locks (and the 831), it helps to understand how they work. Unlike the modern 833 and 951, these locks do not use ball bearings, or even regular lock latches, to hold the lock closed. In the modern style locks, the cylinder will interact with an actuator, and the turning of the actuator will force BBs out or allow them to retract – that’s how most of the high security locks (as I understand it) work – including Abloys and S&Gs. However, the 831 and 826 work differently.

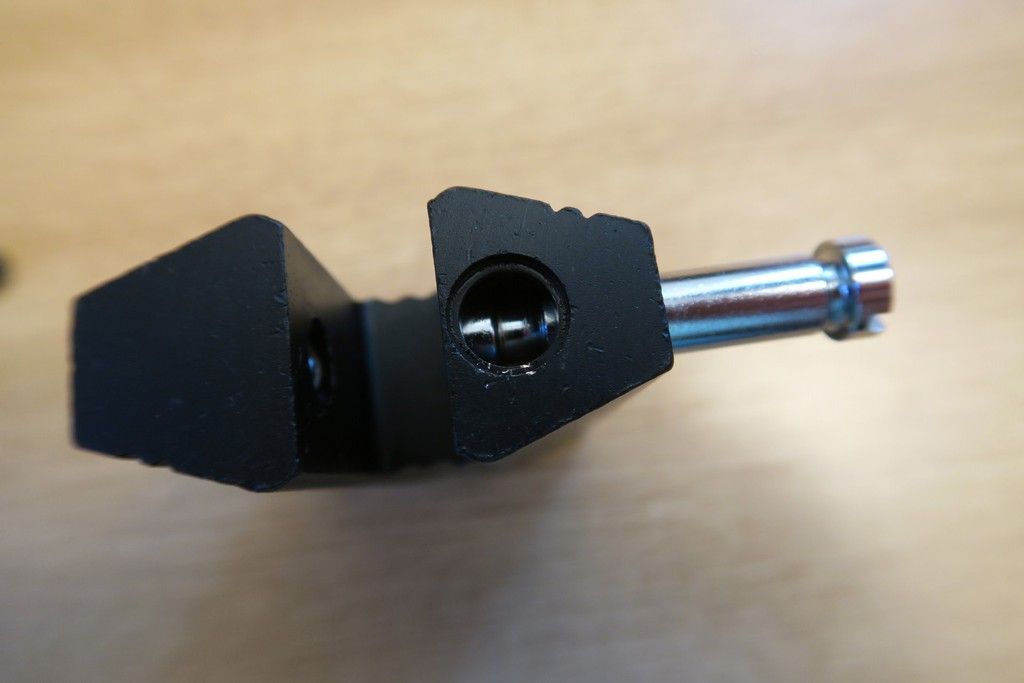

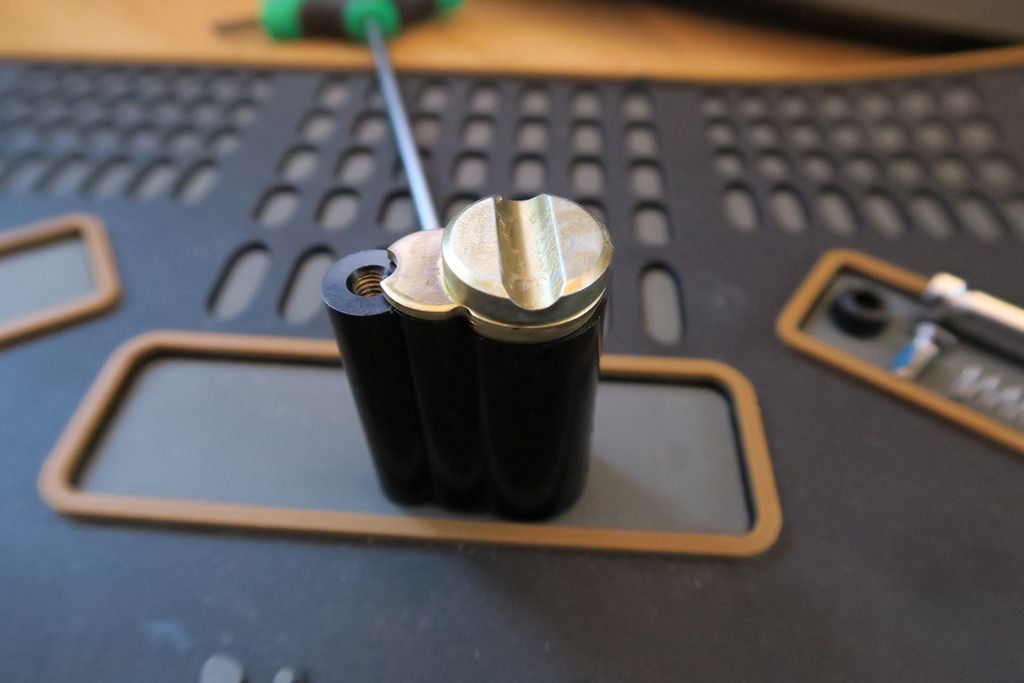

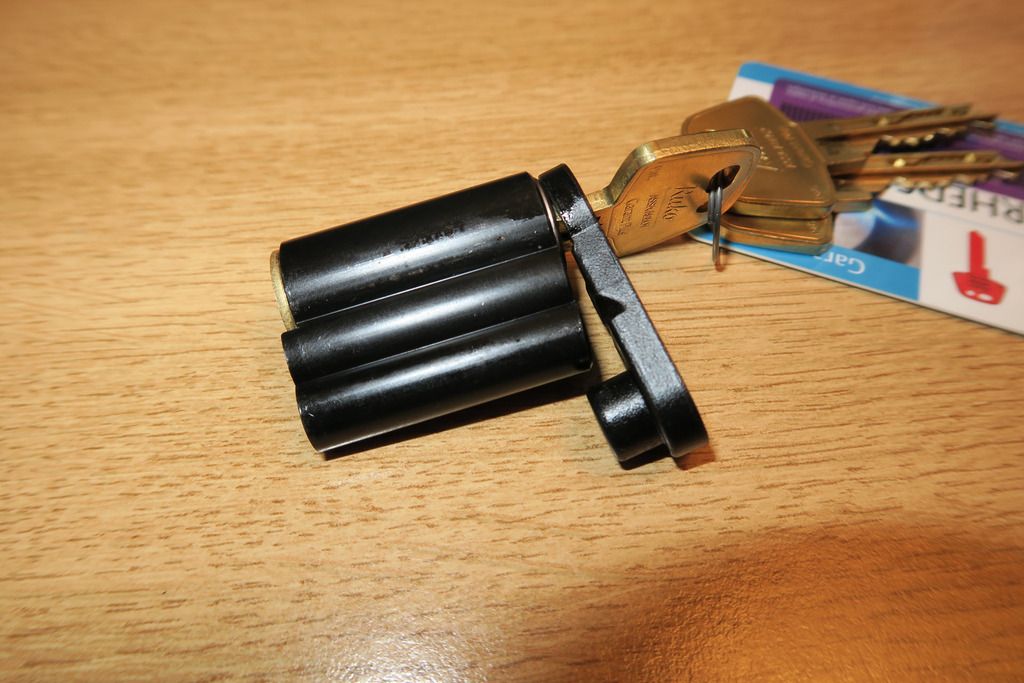

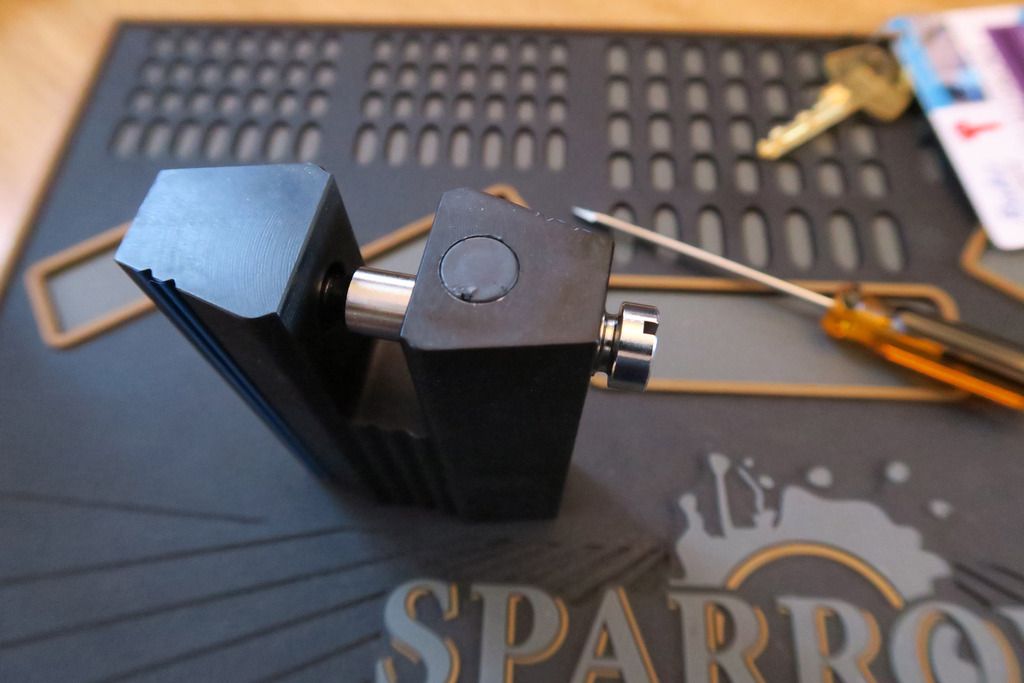

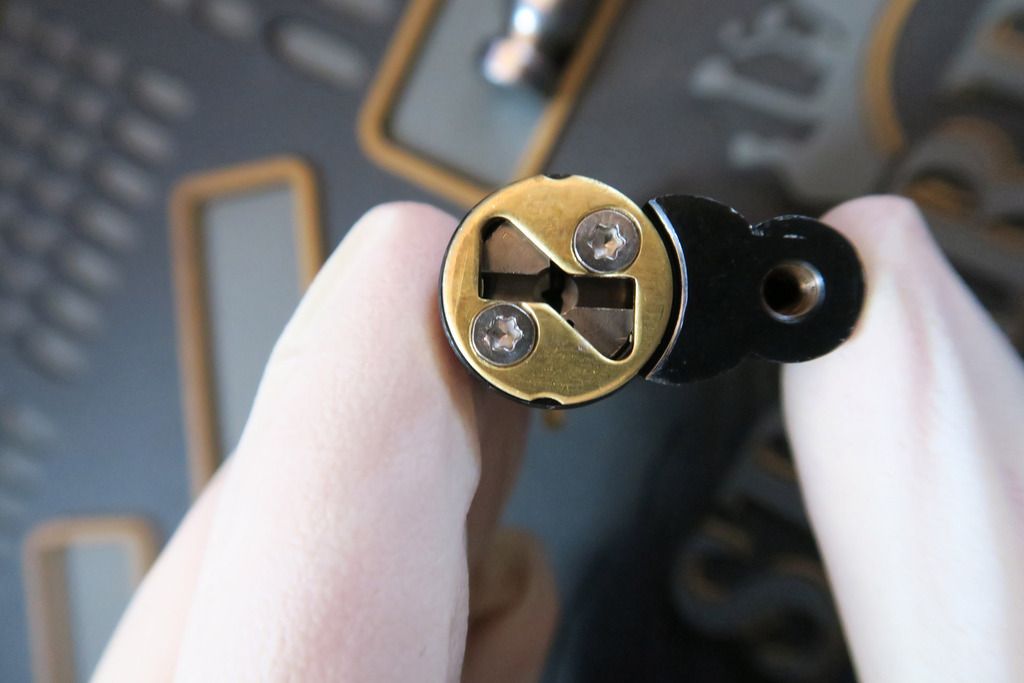

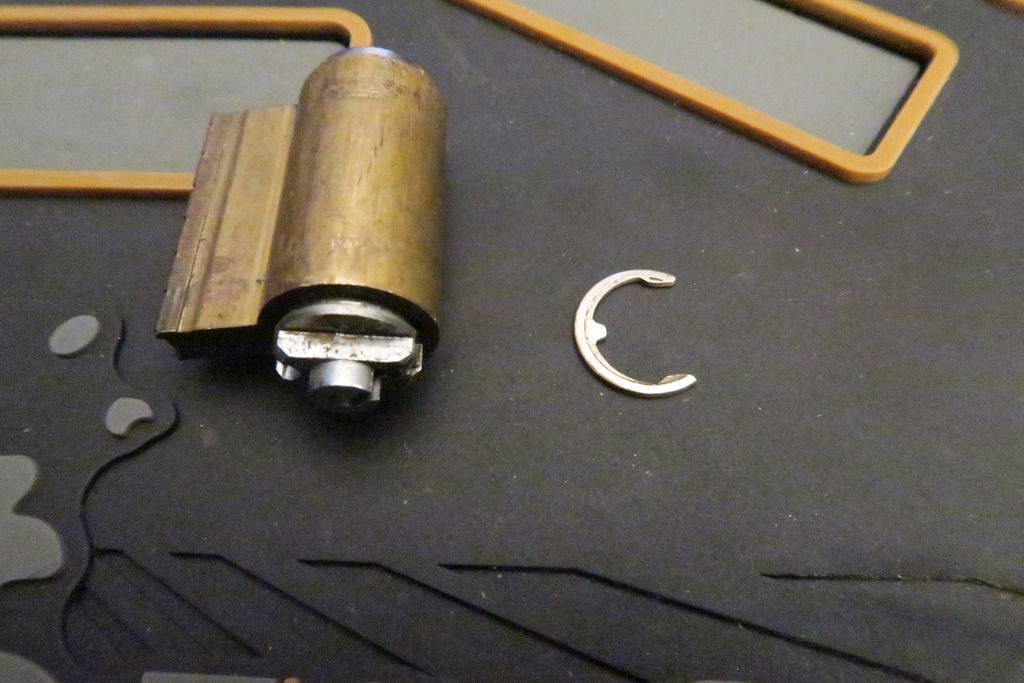

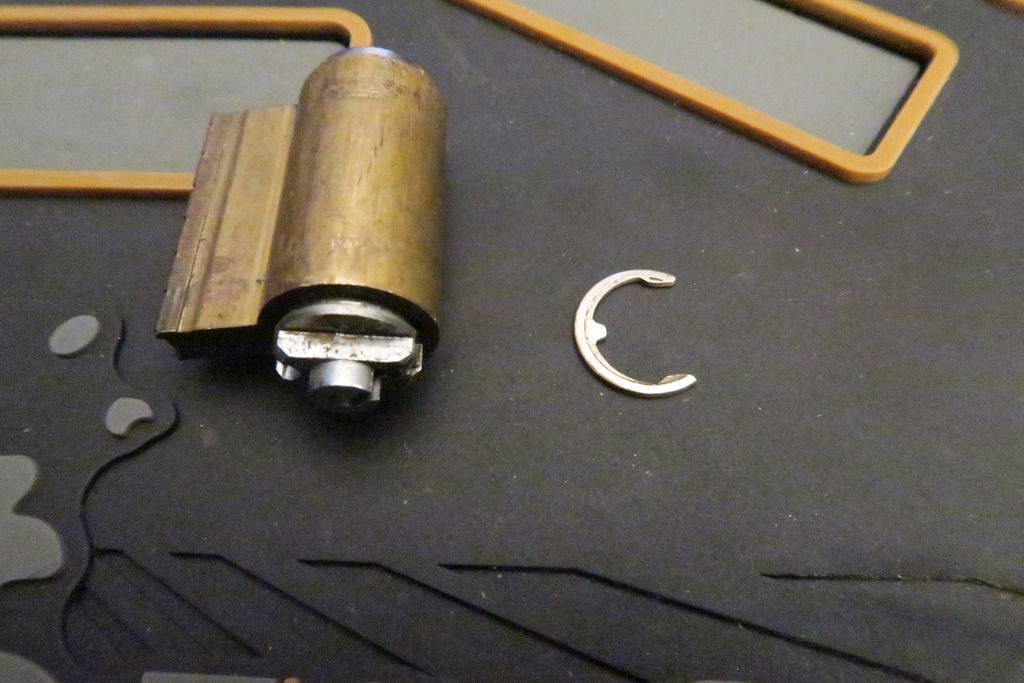

In these locks, there is a cylinder, and then there is a single piece of metal, which has a central round “pillar” area and a long/narrow “post” crossing across it, which is shorter on one side than another. Take a look at this pic:

On the underside of the round section, a cutout is shaped to interact with the bottom of the cylinder. In effect, this becomes the actuator – in fact, you could say that this whole unit is the actuator. However, it is also the locking pole – by turning the cylinder, you rotate this entire metal block, and the ends of the “long” part of it slot into the cutouts in the shackle. In this way, it is impossible to rotate the key inside the lock when the shackle is in the incorrect position – just like how in the modern locks the actuator is unable to turn because the BBs are unable to enter the shackle holes because the shackle is in the way, in this lock, the actuator rod itself is unable to fit into the shackle area because the shackle blocks it.

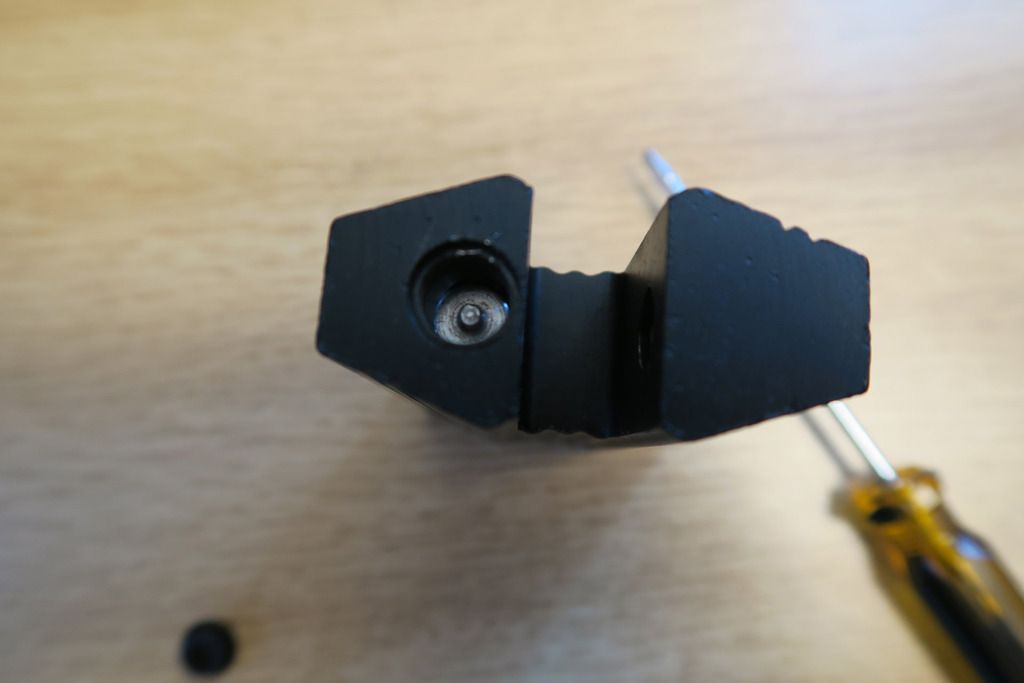

Returning to that original pic, the trick to disassembling this lock is to first ensure that you are using the control key. Rotate to the control position (anti-clockwise), unlock the shackle and slide the plate out. You will then need to drop the shackle down

outside of the padlock (It has two “drop heights”, and I believe that the deeper, and correct one drops around the 180° mark from the closed position, and will only allow rotation for the remaining 180°) and keep rotating the shackle until it’s right up against the body. This allows the shackle locking hole on the closed shackle side just enough of a gap that the actuator can be partially rotated into it – jiggle the key around between “locked” and “control” position while jiggling the actuator or holding the lock upside down and the actuator plate should just fall out. Once it does, you can see the inside of the lock and rear of the cylinder:

(If you look closely, you can see the shackle locking cutout inside at the back of the lock).

Let’s take another look at that actuator plate:

You can see the nub on the top, which fits into the underside of the top plate and stops it from sliding out when the key is not in the control position. You can also see that the ends of the long part of the actuator are worn down from rubbing on the shackle locking cutouts all the time.

From the side, you can see that this is quite a thick and hefty piece of kit – vital for the unit that acts both as the actuator and the locking pole – I’d argue that it’s the most vital part of the lock, mechanically speaking:

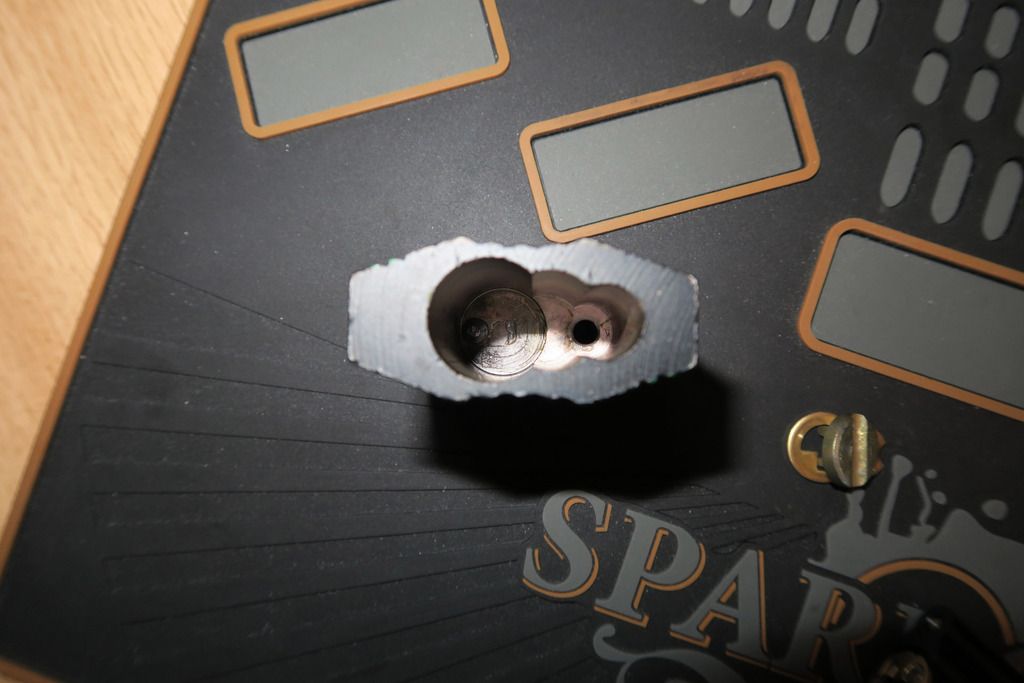

The underside shows another unique ID stamp (4), and the cutout for the cylinder – the round hole for the back of the middle part, and the raised edges which hold the rectangular part of the cylinder in place:

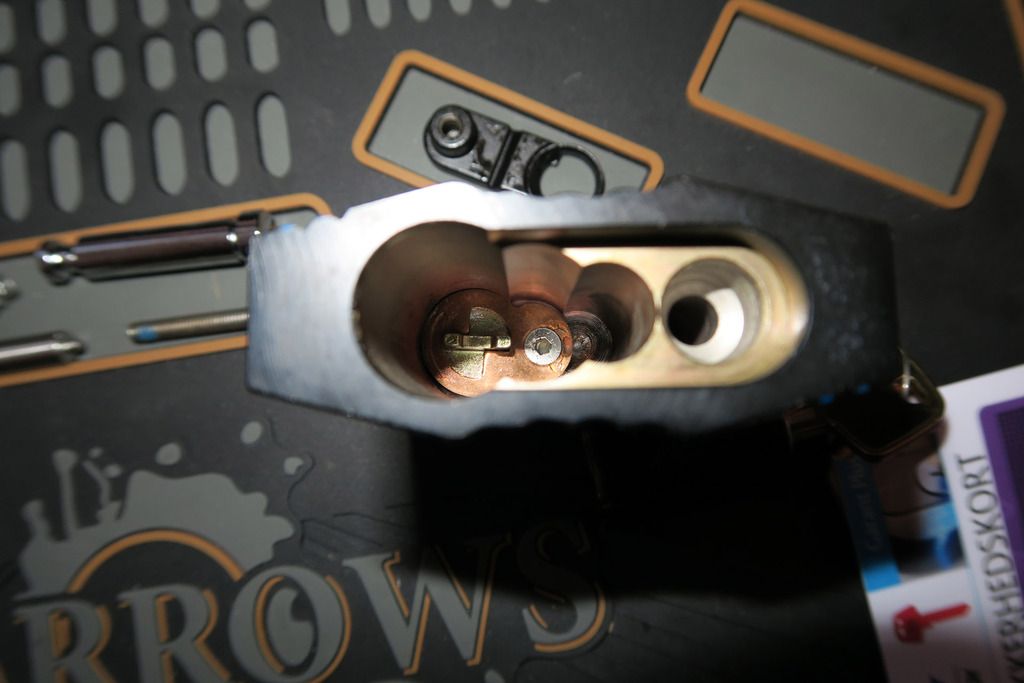

If we slide the cylinder out, you can see that there’s really not much of anything else going on inside the lock body – no fancy anti-drill disks or ball bearings. This lock is simply and a total workhorse:

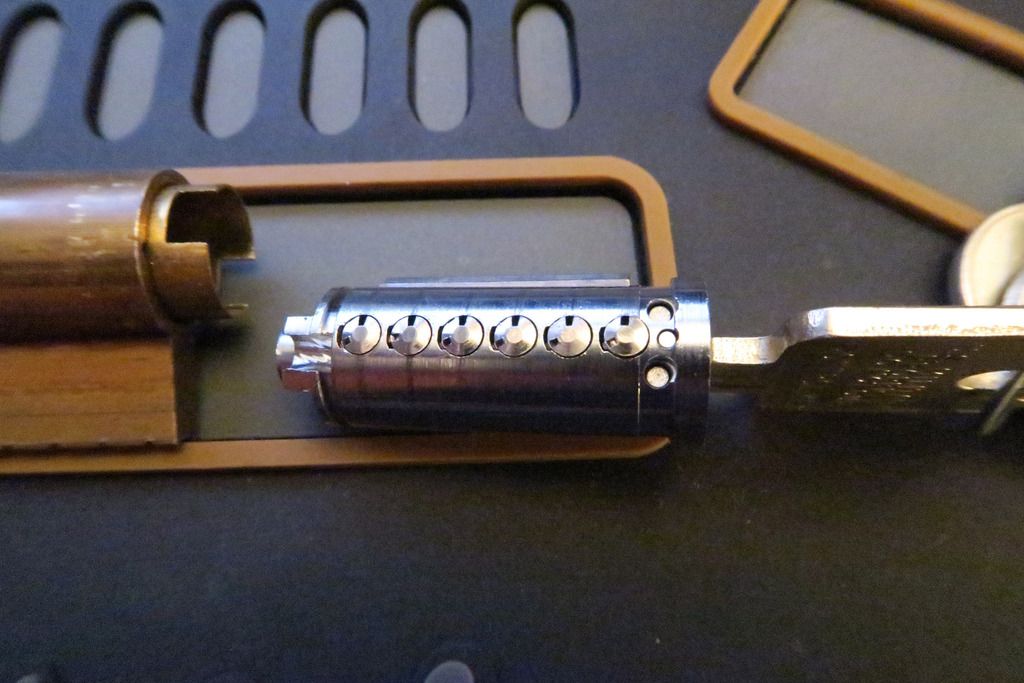

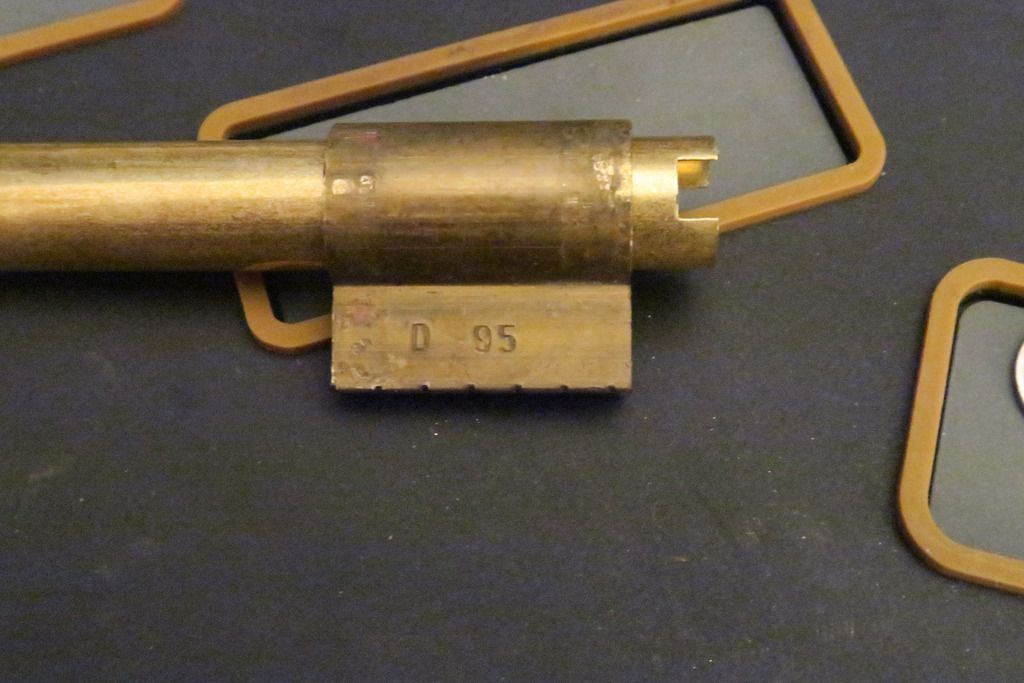

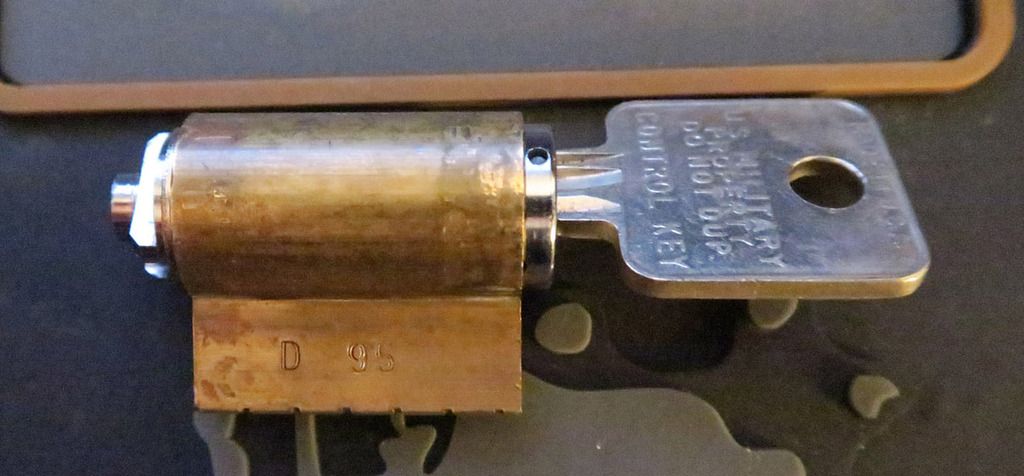

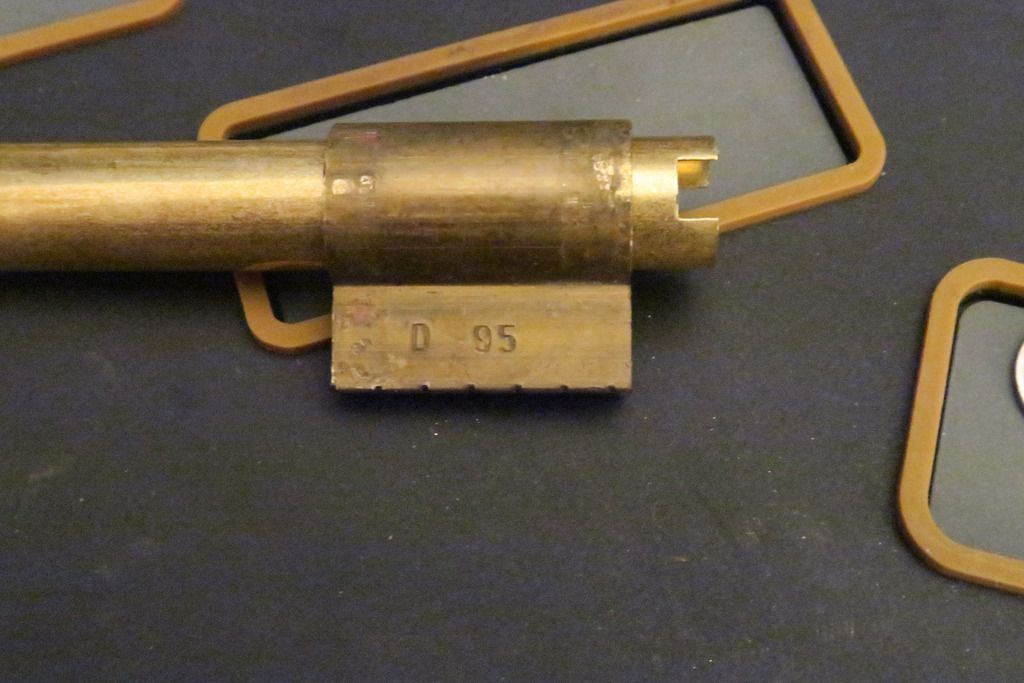

Now let’s take a look at that cylinder! It’s brass, unlike the green ones in today’s 833 and 951 locks. Unlike today, I don’t think that this implied “non-military” – that was just the standard design of the day. I believe that this is the older (classic?) Medeco cylinder:

On one side of the cylinder, “D 95” is stamped into the bible. I wonder what this could mean? Maybe D is for the lock model number – 826D? Maybe “95” is the year of manufacture (if this isn’t the original cylinder), or a batch number, or a UID to prevent destructive replace spy attacks? One of those three, I’m guessing:

The front of the cylinder has seen better days – I guess that’s one part with more exposure to grubby keys/fingers/etc than others!

Let’s get this stripped down! First we remove the C-clip....

Then pop out the core using a plug follower.

Note the three anti-drill pins on the key end of the plug. This one’s also looking a little grubby:

Medeco sidebar removed:

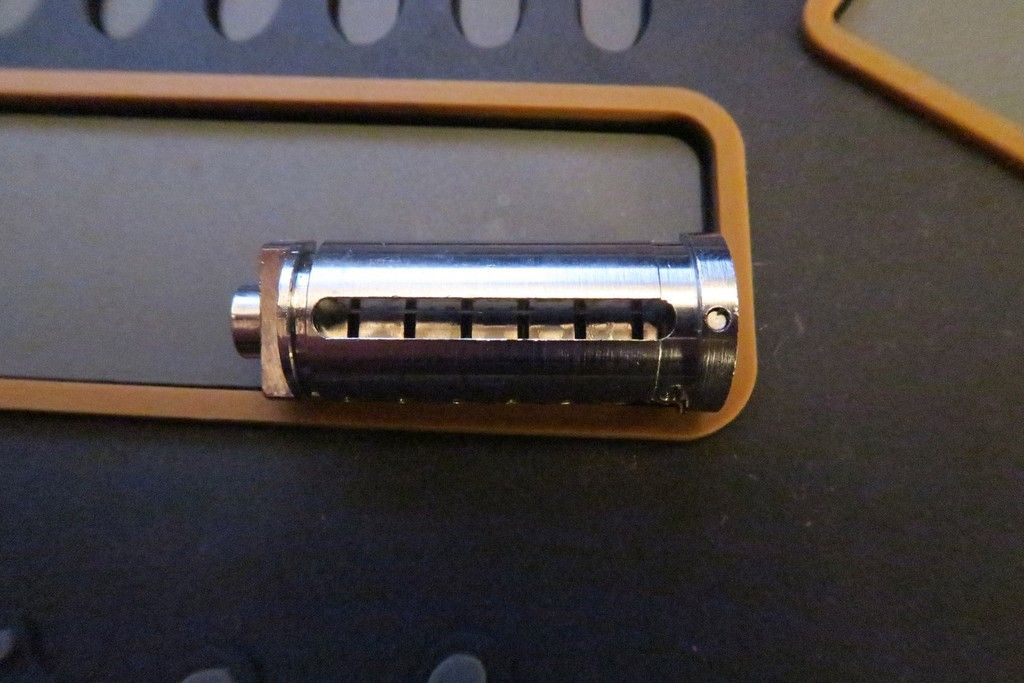

With the sidebar removed, we can see down inside the sidebar cutout:

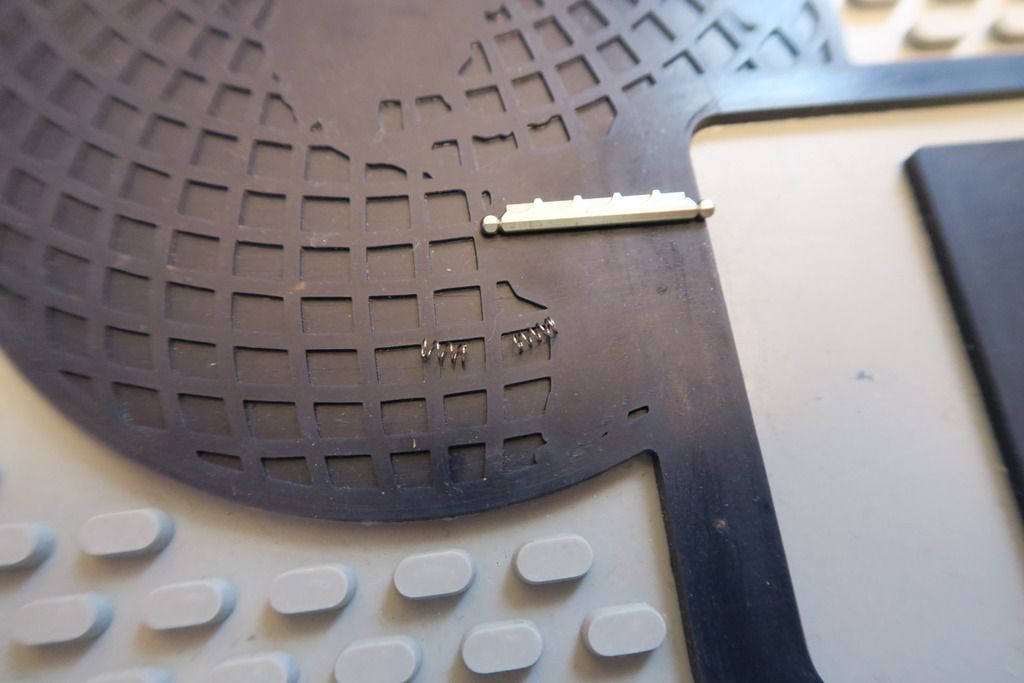

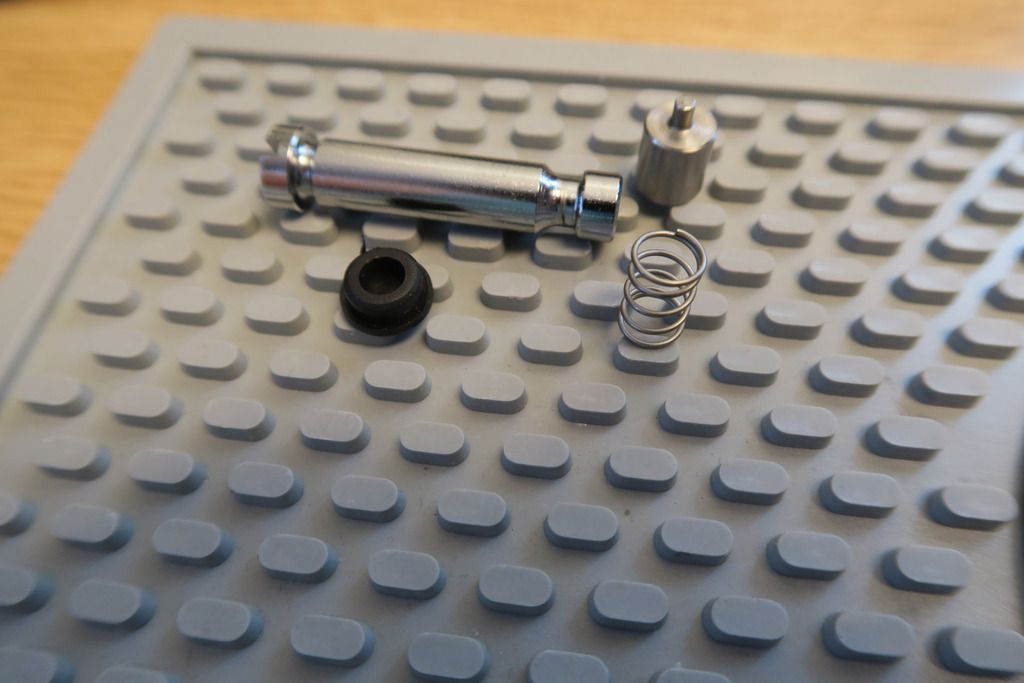

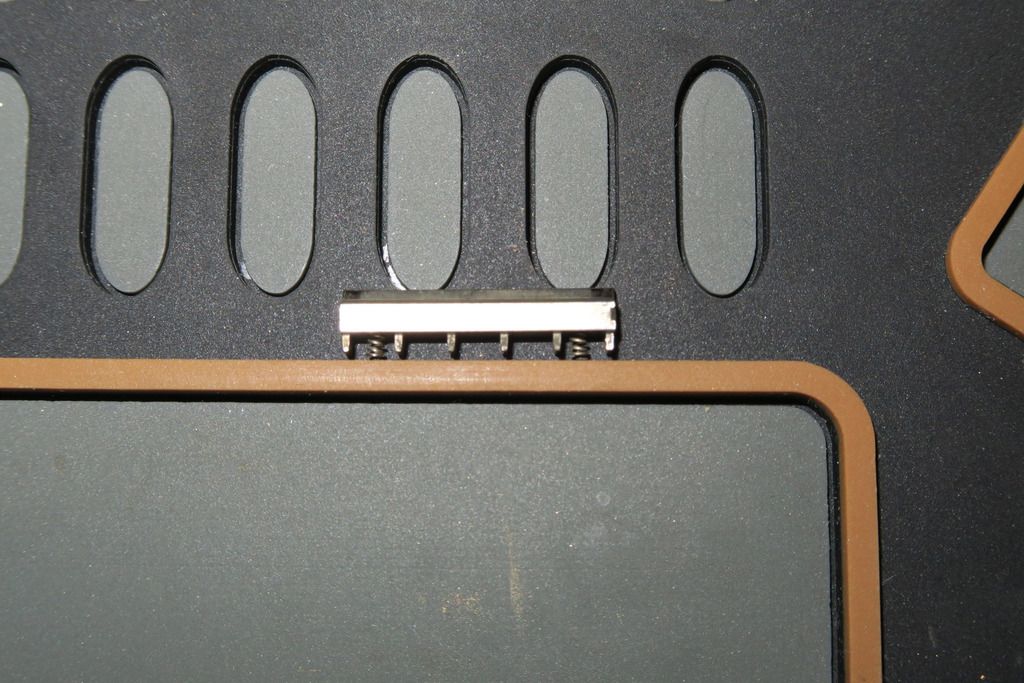

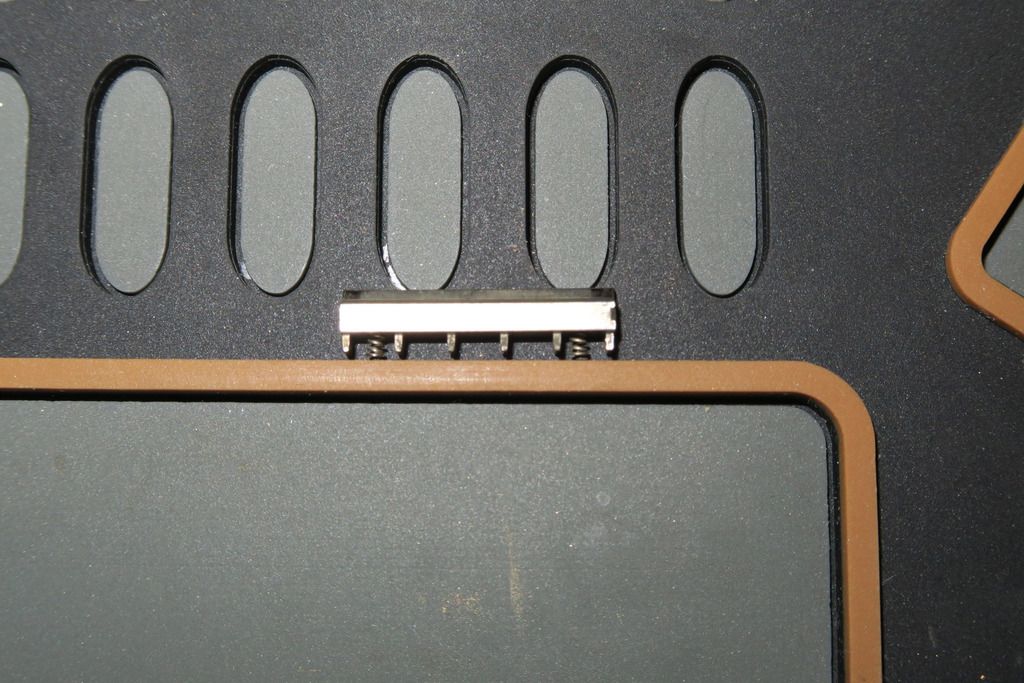

Removing the pins, we can see that they are standard Medeco wedge pins, designed to be rotated by the key to allow the slot in them to line up with the cutout in the widebar slot, allowing the sidebar to slot inside of these pin grooves when rotational pressure is applied to the plug:

All the pins laid out. We have two brass mushrooms and four steel standard drivers in addition to the normal Medeco pins:

One thing that I did just notice – I recall that in my 833 and 951, the key pins have spool or serrated-like, well, serrations in the side of them, increasing pick resistance. These ones do not have that feature and I believe that’s one of the differences between the newer Medecos (either Biaxial or M3, not quite sure of the difference yet) and the older generation.

All the cylinder parts laid out:

Now, since this lock came a little grimy, I decided to clean it up a little and put it back in nice clean working order. At this point I did leave the parts to stand in solution overnight, so the next (and final) post was actually written first, in the meantime. Apologies for any duplicate content or odd continuity errors!

I’ve still not quite figured out what works best for cleaning lock parts, but I have GUNK (car engine degreaser) and WD-40 to hand so I tend to use those – I’ve fallen into the habit of soaking in GUNK (which I’ve seen recommended elsewhere), and finishing off with a quick spray and wipe down with WD-40 – but if that’s a bad way to go about things, please let me know! Of course, I always finish off with some lube – usually Tri-flow for the cylinder and silicone grease paste for the BBs and other hardwearing parts.

I was a little worried that the GUNK would damage the delicate parts or strip that strange S&G gunmetal-grey coating from the components, so I wasn’t sure whether to add the body shell itself or not. In the above photo only all the “parts” were added, but I did end up soaking (half of) the body in this pot too, in the end. I left the components overnight, “stirring occasionally”, and then wiped them all down the next day thoroughly before blasting with some WD-40, wiping down again, and blowing clean (in the little crevices) with compressed air.

Here’s all the parts fresh back from the garage:

Looking much shinier! When I was debating whether to add the pins, one issue I had was “If I dump all the pins into this one pot, how will I know which to put back into which pin stack?”. I figured I’d just use the key trick – put the key into the plug and load the pins into it, testing for correct height and moving where appropriate – but one thing I forgot to factor in was the rotation. Because Medeco pins rely on a specific angle for the side cuts in them to line up with the sidebar channel, you can’t rely on just the height of the pin – you also have to check whether a gap has been left clear in the slots within the sidebar channel. So, that provided an interesting little side puzzle later on

.

Here’s all the parts loosely tossed onto the pinning mat:

Photo of celebration showing “all dark” in the sidebar channel slots after getting the key pins correct, finally:

The driver pins I managed to figure out by studying my old photos – luckily everything before the “big clean” was already photographed, edited and sorted by then

Cylinder re-assembled and working. Yay!

In the process of lubing the cylinder. I just sprayed a little tri-flow at each end and zipped/rotated the key a bunch until it seemed like the lube would have worked in by then. Not sure if there’s a better way...

Lock mostly re-assembled at this point – just had to fiddle to get that actuator bar in there!

All reassembled and done – you’ll notice that I’ve gotten the key tag sorted now (along with all my other locks):

Thankfully the gunk didn’t damage the lock’s appearance (although it has probably “lightened” it a little, due to removing the black oily grease stuff that was on the outside and especially in the embossed lettering stamps).

And that’s it! We’re done with this lock, and now have only one final lock to look at... Time flies when you’re having fun!