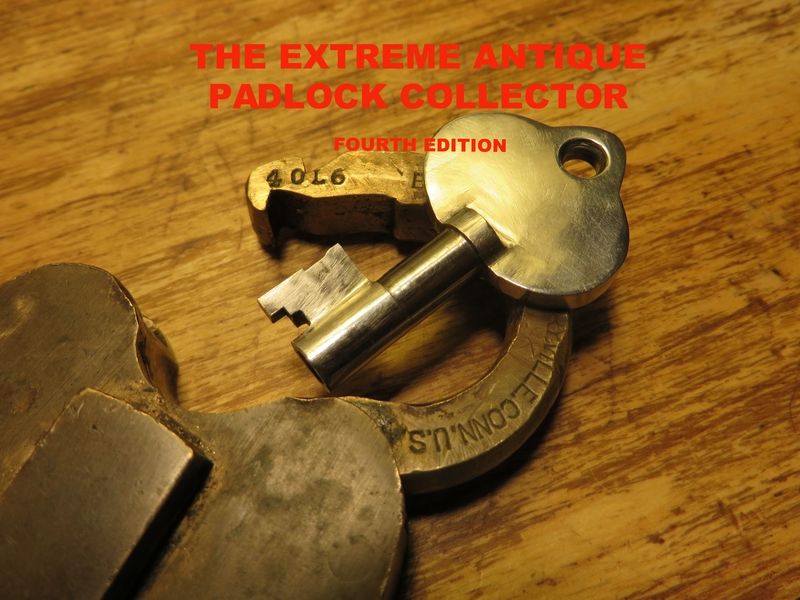

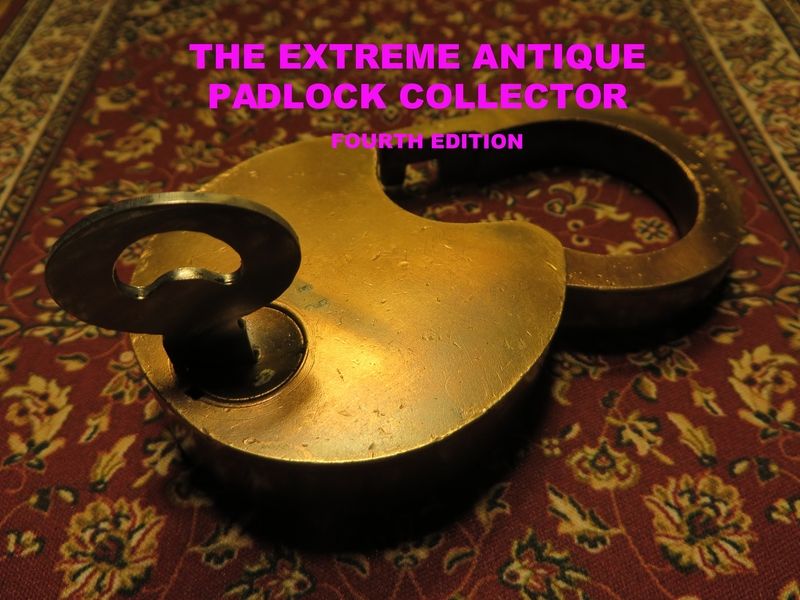

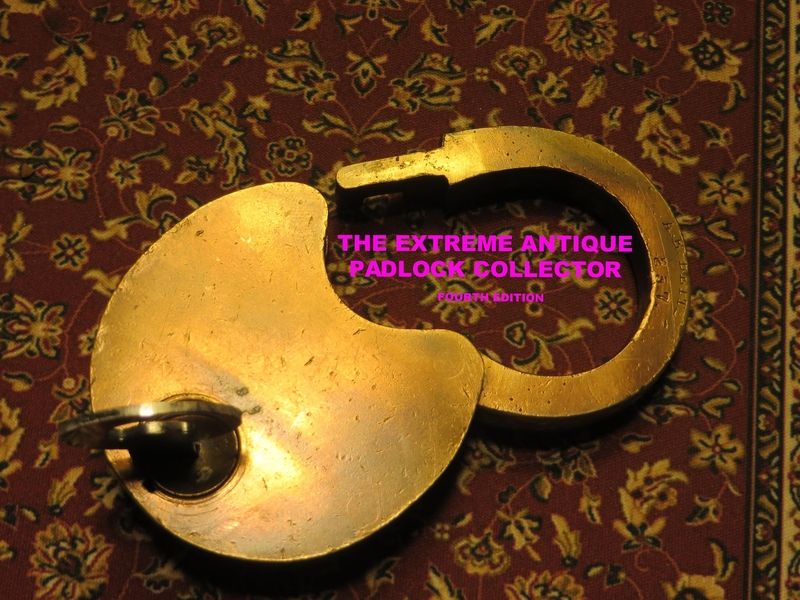

Not too long ago, I was expecting receipt of a SLAYMAKER padlock (like the one shown below). Unfortunately, the padlock was stolen in the mail, causing me to take some voice in Papa Gleb's thread of locks not received from Jeff Moss. In my case I had already spent a day making a rather nice stainless steel key blank for my anticipated treasure, but good old Murphy struck again. Naturally, I would obtain a new lock when one became available on EBAY.

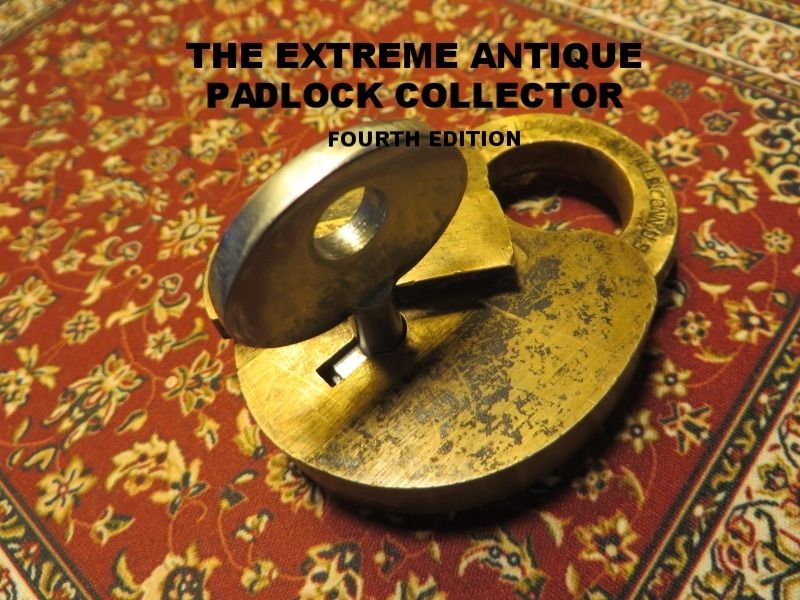

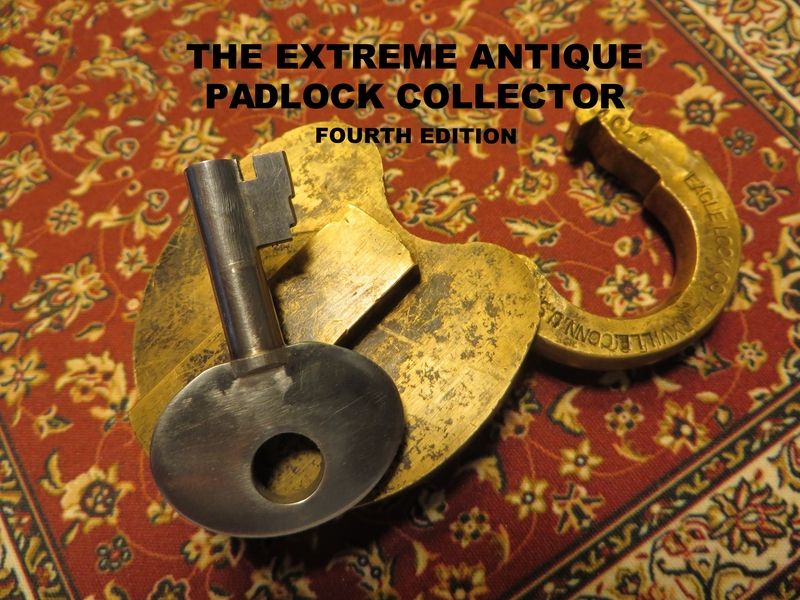

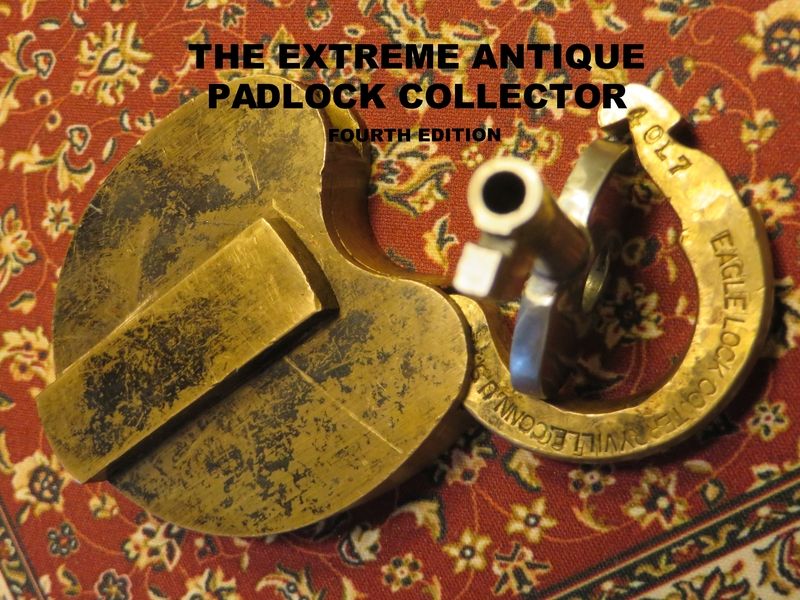

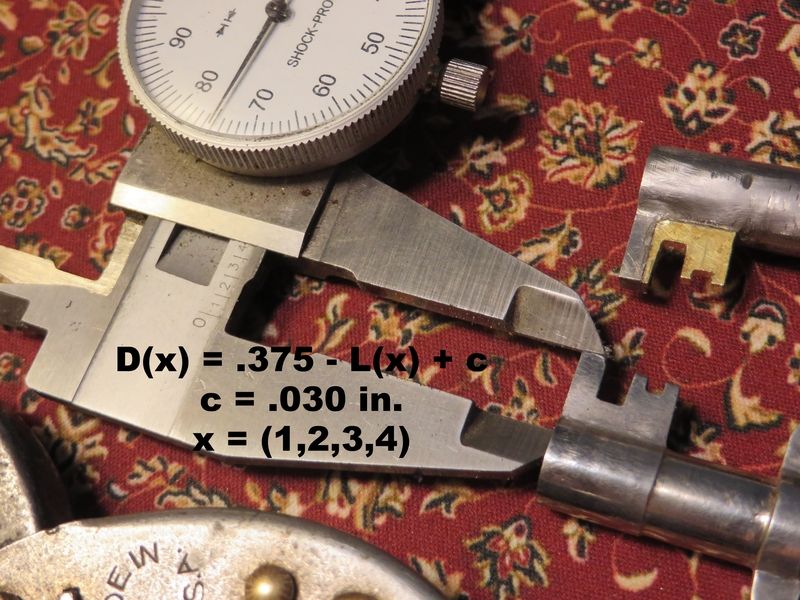

My latest padlock is marked "1948" on the shackle, most likely the date of manufacture. Although, these padlocks were abundant throughout the 1960's. I believed my latest key-less SLAYMAKER padlock would be a breeze to open, adopting some confidence in making keys for similar CORBIN/SAFE padlocks. Nevertheless, my own arrogance got the best of me, learning there is a huge difference between these padlocks. The SLAYMAKER design (a four lever tumbler) has extremely tight tollerances between the gates and fence. This would mean, if I was able to decode the lock correctly (using a special tool, not shown), I would only get one chance in cutting my stainless steel key blank. There was no way I was going to take the risk. I tried using some clever methods described in my book to get this lock open. But failure was at every corner. In general, a working key should feel like twisting a wood screw in soft pine, just as the fence becomes engaged into the gates of the tumbler stack. I needed a better option, and yes, it would have to be an extreme one.

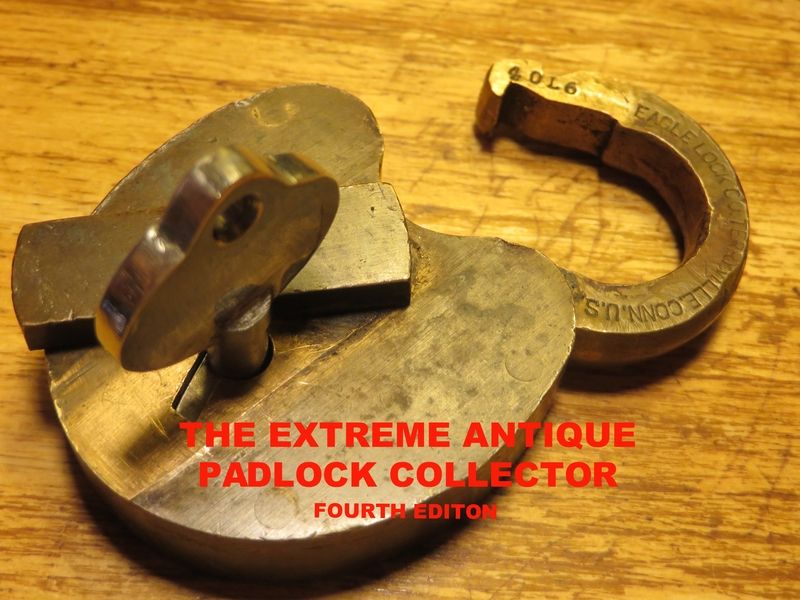

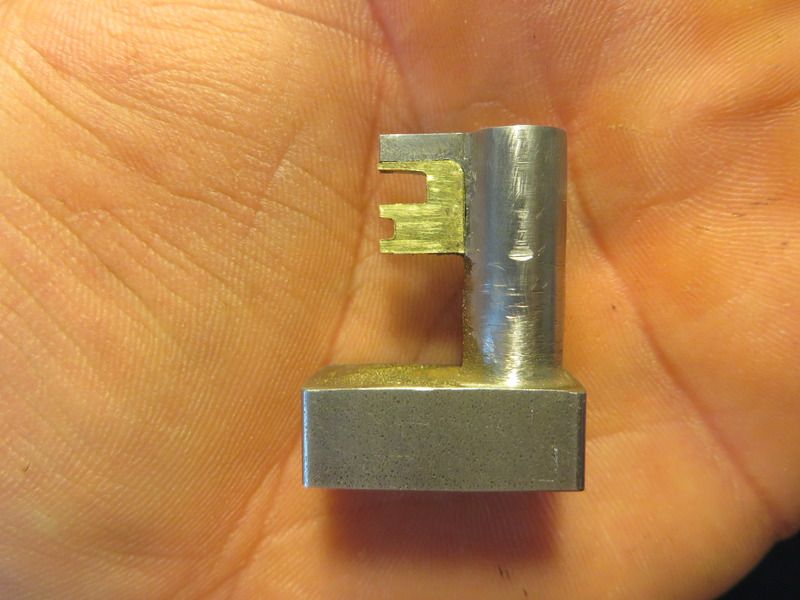

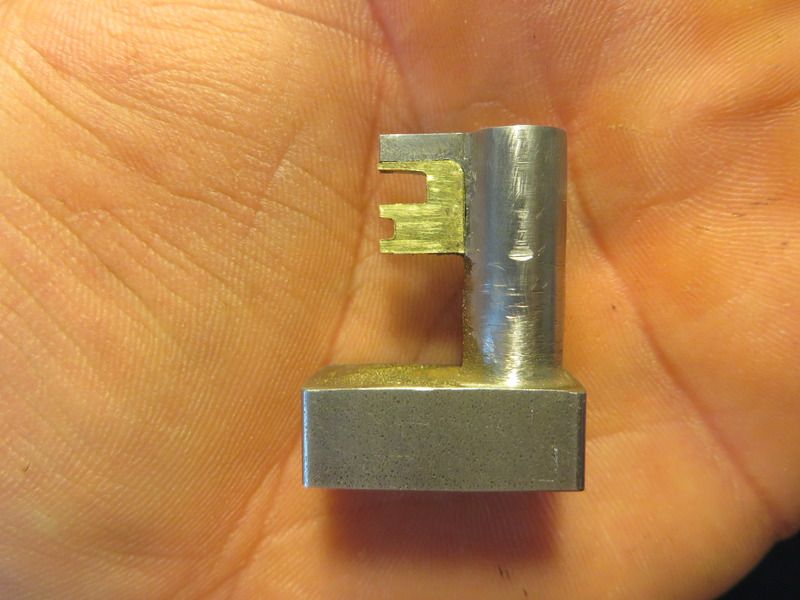

So, I invented a special barrel key unique to these SLAYMAKER padlocks. The idea is so cool, I almost wanted to write another chapter in my book, but enough is enough. I was able to determine all of the essential bitting, sketetonizing the key. My barrel key tool has one amazing feature; the bit section above the driver bit is removable. The little brass section is firmly super-glued onto the bit area. I was able to open my lock on the first try, but I needed a wrench to do it. I quickly realized the second bit cut for lever two was not cut deep enough by .005 inch. With the lock open, I have all the data to make my stainless steel key blank into a working key (a picture for another day). You folks who follow my thread are getting a real taste of the kind of methods that you will find in my book. They don't teach you this stuff in locksmithing school.

http://www.blurb.com/b/6565733-the-extr ... -collector

http://www.blurb.com/b/6565733-the-extr ... -collector