manipulation #29Wanted to share with you an '

Oldie but Goodie'

DIEBOLD 900 Series

I'm identifying this one as a very early version in the 900 Series (produced from 1954-1970). But corrections are welcomed!

NOTE: The dial, drive cam, and homemade spline key are NOT ORIGINAL to this lock. But the odds of me finding these

pieces or a cover plate (also absent) are probably pretty slim. So I figured it's time to get it running with what I have.

More clues as to its' age?... there is no re-locker of any kind, nor is there a ball detent to help stabilize the bolt.

Ever wonder just how much is

too much?

Yeah, I'd say this is a bit excessive on the lube. Any more and this thread's gonna be XXX. lol

In fact, I didn't even realize there was a dial ring bushing

separate from the dial. It wasn't until

I had chipped away most of the grease when I realized it had shifted and it could be pulled off.

Took a while, but here it is all cleaned up and ready to be

properly lubricated. Didn't think to take

another picture after I greased it, but if I had it would look nearly identical to the above photo.

I use AeroShell 22 Grease. A very thin, nearly invisible layer on

both bearing surfaces

will do just fine. This dial will now run smooth and true for a long time to come.

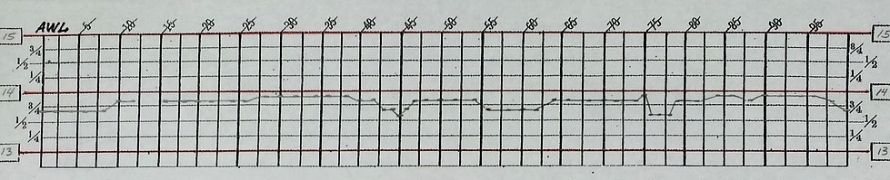

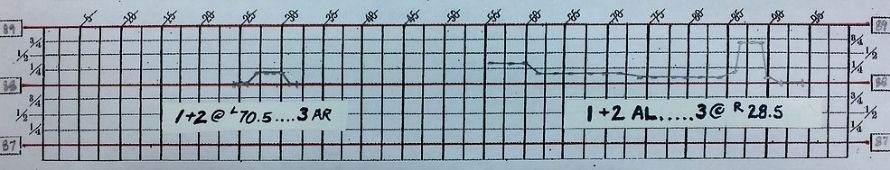

Group2 ... 3 wheel ... key change ... spring-loaded fenceCONTACT AREAApproximately 7 incs wideLCP

Group2 ... 3 wheel ... key change ... spring-loaded fenceCONTACT AREAApproximately 7 incs wideLCP 88 . . . . .

RCP 95

ROTATIONAL CONVERSIONunable to reliably determineREADINGSLEFT contact point

ONLY...taken in

tenths every 2 incs

Many of the locks throughout this thread were manipulated by focusing on the RCP.

LaGard, Ilco, Mosler, S&G, etc... these locks all have what I call a 'normal' drive cam.

The right-hand side of the cam's gate has a gradual slope, allowing the lever nose to

ride up & out more easily when being locked. Therefore the RCP gives us more info.

Looking at the U-shaped gate on this Diebold's drive cam, both sides are rather steep.

If you look closely though you'll notice one side (left) is slightly rounded in comparison

to the other - that's where we'll focus our efforts. And by the way, you might approach

an old Diebold dial and think you have this all figured out... when on the other side of

the door lurks a 178-23 (which uses a normal drive cam AND LaGard type wheels)!

Sorry to throw a wrench into the mix, lol... but thought I'd keep ya on your toes

Another thing; One of the first things I do when I sit down in front of a Diebold is lower my expectations.

Generally (

but not always) the rate of change in your readings will be minute with these. So we want to

change our mindset to view even the smallest differences as relatively large fluctuations. Tiny=Large.

My readings are usually taken in tenths. You might read in eighths. These are two slightly different

scales, but we can expect roughly the same thing.

I'll be expecting at most, a 1 or 2 tenths

rate of change...

you will likely see a rate of change of approximately 1/8, give or take.

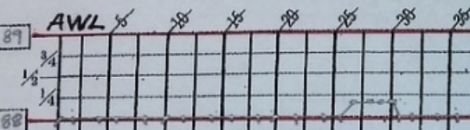

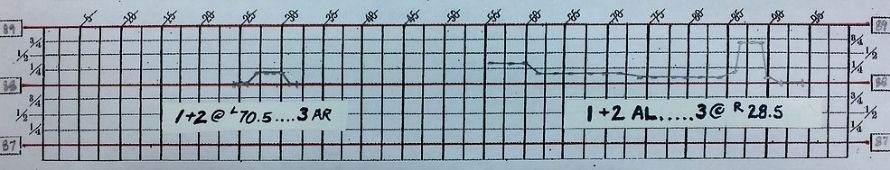

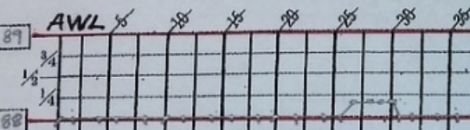

BINDING ORDER3 - 2 - 1UNKNOWN COMBOL39 - R88 - L29The first spin (AWL) produces a promising gate (28.5). The other area (55-90) actually provides for some good discussion.

Looking for the

best reading our eyes are naturally drawn to 70. But if we take a look at this area again, but with something

else in mind (looking for the

greatest rate of change) then we must also consider 90, where a change of 2/10 has occurred

Neither of these (70,90) are confirmed nor discounted at this time. We just dunno. So let's focus on what we

DO know... 28.5

(the portion to the left in the below graph)

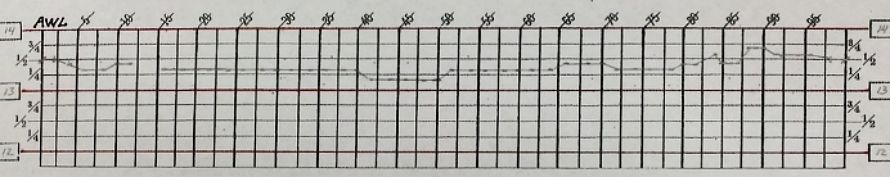

(the portion to the left in the below graph) shows my isolation attempt to tag 28.5 to a wheel.

I chose to use 70.5 (best reading on graph) as a window. Parking wheels 1&2 there, I run w3

by itself through the area of 28. The gate does show up and I can successfully tag 28.5 to w3.

-

-  - R28.5

- R28.5Had it

not shown for w3 I would have continued isolating wheels.

Wheel 2 next, then finally w1... always leaving the others at 70.5

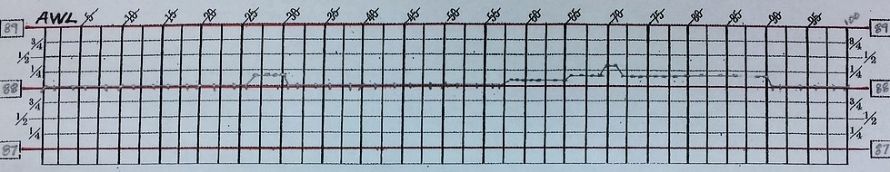

(the portion to the right in the above graph)

(the portion to the right in the above graph) I hoped running 1&2 through the area (55-90) would now give me

something a little more definitive, considering w3 was now at its' known gate. But I was NOT expecting it to be

quite so obvious! lol. An enormous gate sig appears at 88. It jumps by 1/2 an inc then plunges back down 6/10.

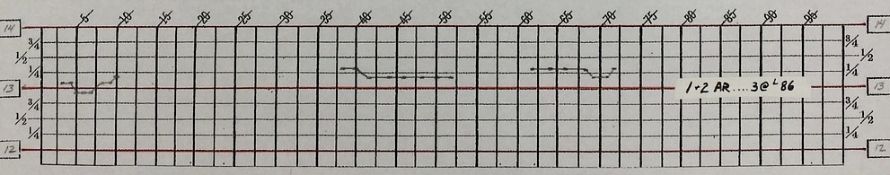

Again, I'm looking to use isolation as a means for tagging this gate to wheels 1 or 2.

I focus on isolating w2 first. I want to take 3 readings through the area at 84, 88, 90.

The way in which I want to do it though essentially leaves me with a L-L-R configuration.

I want to park w1 at LEFT 70.5 ....but I also want to run w2 LEFT through the area of 88.

L70.5 - AL - R28.5Why am I being so picking about w1? Wouldn't it be easier to just park it with right rotation?

1. The good area I'm looking to park w1 within is only 1 inc wide (70-71).

2. We know w1 always has the largest rotational difference of all the wheels.

3. From the start I was unable to determine exactly what these differences were.

I'd rather just alleviate any doubts by placing it exactly the way it was originally found - left.

4X LEFT......70.5

3X RIGHT....80

3X LEFT......842X RIGHT...28.5

The simplest way to look at this is to consider our '

target number' for wheel 2 (LEFT 84).

After placing w1 @ LEFT 70.5, we're FORCED to pick up wheels 3 & 2 with RIGHT rotation.

That's ok! Go ahead and pick 'em up with right rotation. Continue around until you've PASSED

the target number (84) and stop at, lets say 80. Go LEFT, pick 'em BACK up and bring em to 84.

Summary: Pickup wheel(s) and bring them beyond the intended target using the undesired rotation.

Then switch directions to pick them up again and bring them to the target using the desired rotation.I'm now set up to push w2 around left taking readings at 84, 88, and 90.

Naturally, w3 is brought to its' known gate (28.5) before each reading.

And w1 remains undisturbed at L70.5 throughout this process.

Reading peaks at 88 and I can now tag it to wheel 2.

- L88 - R28.5

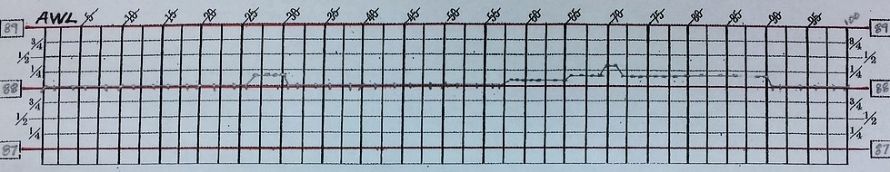

- L88 - R28.5Spinnin' for the money now..... I cash in at 40

OPEN: R40 - L88 - R28.5Some other Diebolds if you're interested:

p.6

Manipulation#11 Diebold

17823p.8

Manipulation#13 Diebold

177-23p.11

Manipulation#19 Diebold

177-39. .. ... ... ....Some Thoughts on Readings.... ... ... .. .Recall my initial AWL gragh and the gate signature that was produced at 28.5

The photos below illustrate this gate as seen through the dial.

The first reading is taken with AWL 26 (prior to the gate).

The second at AWL 28 (gate is now under the fence).

My

My eyes identified these readings as

88 even &

88 2/10.

You however might be looking at these right now

with a slightly different interpretation.

88 1/10 &

88 3/10? After all, both readings are on the verge of being

the next division up. Point is, none of these views are incorrect...

as long as you stick to them throughout

the entire manipulation. If you're consistent with the identification of your divisions, fluctuations will show.

And we've all experienced what I call 'gray-area' or 'gray-matter'. This is when a reading lands perfectly

BETWEEN two of your divisions. Exactly between 1/4 and 3/8 for example... whatcha gonna call

that?

These are decisions that should be made before you ever start spinning, lest you find yourself in one

long drawn out debate that continues

all the way around the dial. Every dial and opening index can

pose new challenges. Spend whatever time necessary within an inc. Be decisive... then

stick to it.

Reading in tenths leaves less room for gray-area, but certainly doesn't alleviate the problem entirely.

I still sometimes end up in "the great debate." And then there's dials that don't take kindly to tenths,

and you're left working within the width of a human hair. Literally, lol. Sometimes reverting back to

eighths just makes sense simply because it suits a particular dial. Whatever breeds consistency.

Fluctuations are all relative to the footprints left behind us. We're constantly comparing our

current reading with the previous reading(s). Noticing these changes will be dependent on

our ability to call a reading what it

is and

repeatedly doing so through the entire process.

Happy Spinnin' Folks