I cracked another vault.

A Chubb-Mosler and Taylor.

The call came in at about 12:30, a mortgage and investments kind of institution was locked out since that morning.

I had just finished a re-key at a Hotel and I was hungry. I picked up fast food, got ready and left at 1:30 or so.

It was out of town, quite a ways, about a 3 hour drive. I arrived at 4:30, half and hour before closing time.

I was told that the bottom comb wouldn't open. It always did before but not today, they tried all morning.

From experience, I know these people lie to me all the time. They never want to admit when they fu*ked up.

I guess they're afraid of getting in sh*t with they're superiors and they invent all sorts of stories

that often don't make any sense...But, I know what questions to ask and how to ask them,

and I've become a pretty good judge of character.

Like Frank Colombo, head cocked, squinty eye: "Oh! uhh, one more thing..."

...I normally decipher the truth. But this time, there was no need to "pull the truth" out, I believed her, she was genuine.

As always, I looked after my comfort and I pulled a chair to the door. I trusted the manager, so I approached the lock

with malfunction in mind, not a fu*k up. I could tell it was old, It had those clear plastic dials and rings. They were all

yellowed and cracked. It felt old too, sloppy, gritty, screechy, it was warped a little and it was hard to read from a faded index. I grabbed my Lock Amp and started my diagnostics. The business was now closed and the manager had to stay, so 2 other employee decided to stay as well and, "hang out". They were joking around, LOL'ing and talking behind other employees backs. I don't like this kind Of BS, it annoys me and I was trying to listen to the lock so I "smart ass-ly" said: "Don't go talking behind MY back,I can hear everything with this thing" I was pointing at my Amp.

The two loud mouths left and Mrs. manager apologized for their behavior.

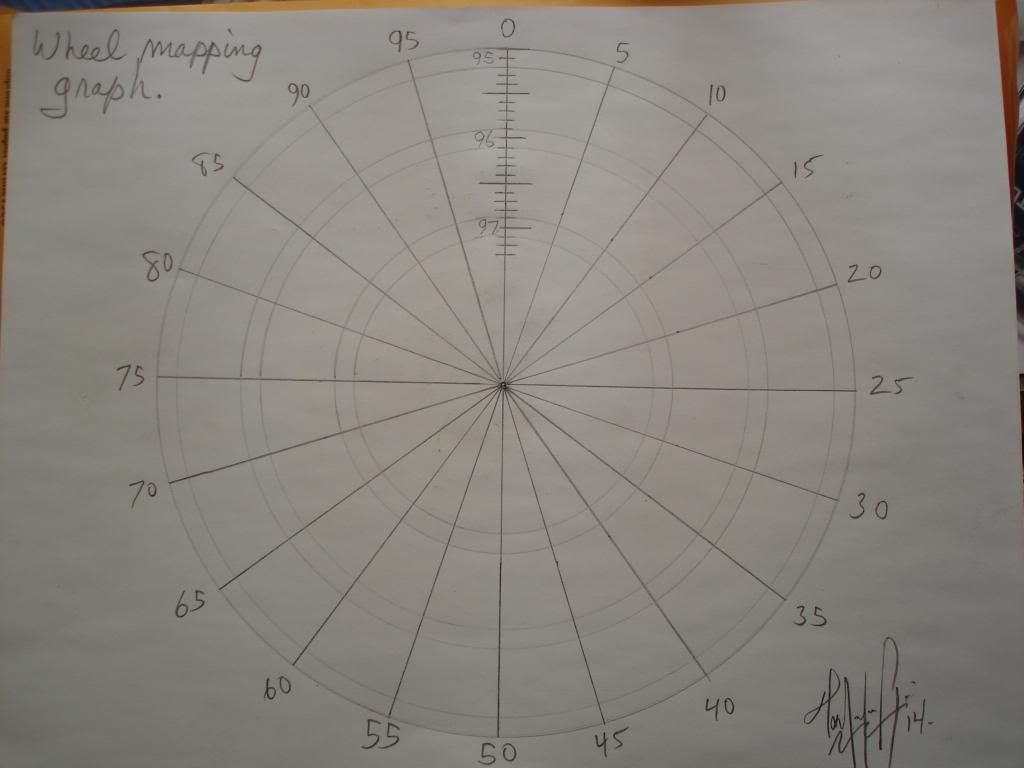

I had the numbers in hand, but started a "mini manipulation" to verify the numbers, just to be sure. I could easily find the first 2 but not the last 2. I did finally find the third number, but not where it was supposed to be? Maybe a wheel slipped, and if it did, the last wheel would be off it's number too.

The third # was off by 32 so I adjusted the last wheel to match that 32 shift, but no, didn't work.

I spun AWL and started over, 1st gate, OK. 2nd gate, OK. So far so good, then the third gate, 32 away from where it should be and...Nope, it's not there anymore??? I tested it a few more times to no avail, it moved again???

I ended up finding it again but no where near where it was.... Fu*k!!! That wheel didn't slip, it's fu*king UNLOCKED!!!

So I left it parked there, I wasn't going to go chasing that gate again. then, I very, very, verrrrry gently moved the last wheel,

I was hoping that the 3rd wheel would stay put and only the inner hub would turn. I moved it in 2 increments after checking the CP's until the fence dropped in. It took 2 hours but I got it...

I turned the handle, pulled the door opened, got that instant

hormonal euphoric gratification and proceeded to repair it. It turned out that the last TWO wheel were unlocked...

I was all done at 7:00, had supper and arrived home at 10:30.

What a day! A fourteen hour day...

I told the tale to a fellow safecracker as having "safeman"s luck"...

He replied: "You wouldn't have "safeman's luck" if you weren't a SAFEMAN...You knew what you were doing...

...And, YOU did it...You're one hell of a safeman"

Man! Do I ever love my profession, it's right after sex...

http://s1155.photobucket.com/user/Altas ... ult%20door

http://s1155.photobucket.com/user/Altas ... ult%20doorM.

Oh! And inside, a bunch of lockers all fitted with S and G's and thousands of SD boxes...

That is a really nice dial.

That is a really nice dial.

But geez as if the locks aren't difficult enough. Then you have people with

But geez as if the locks aren't difficult enough. Then you have people with