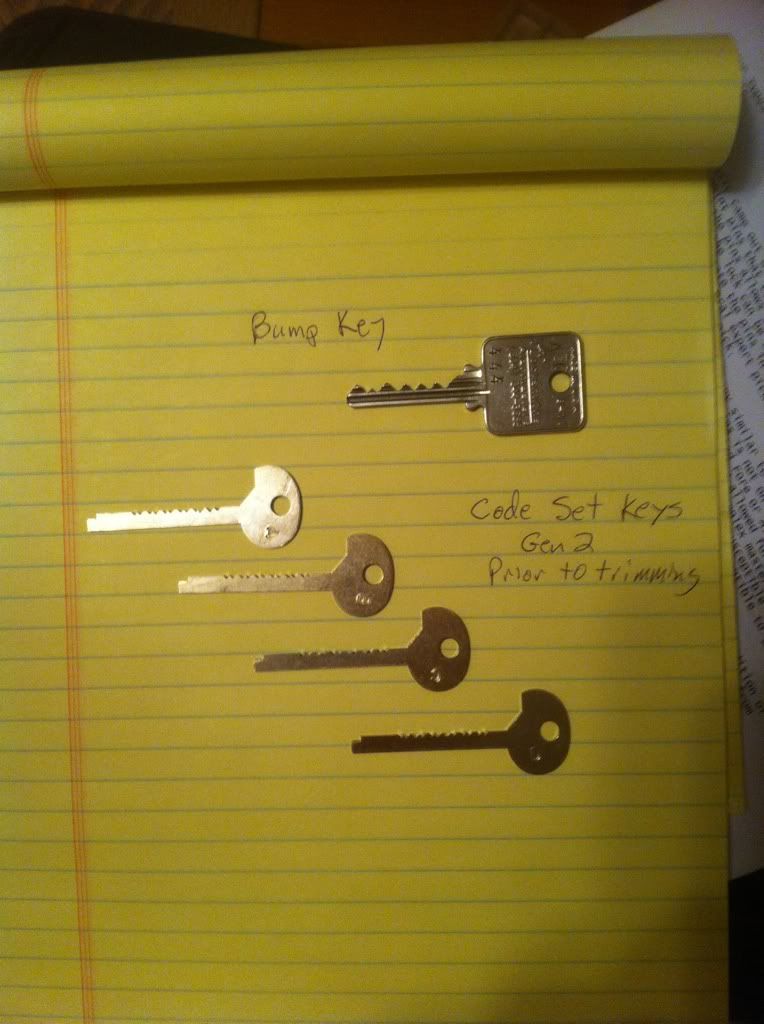

Medeco Code Keys- (Generations 2 & 3 all 20 keys are cut)

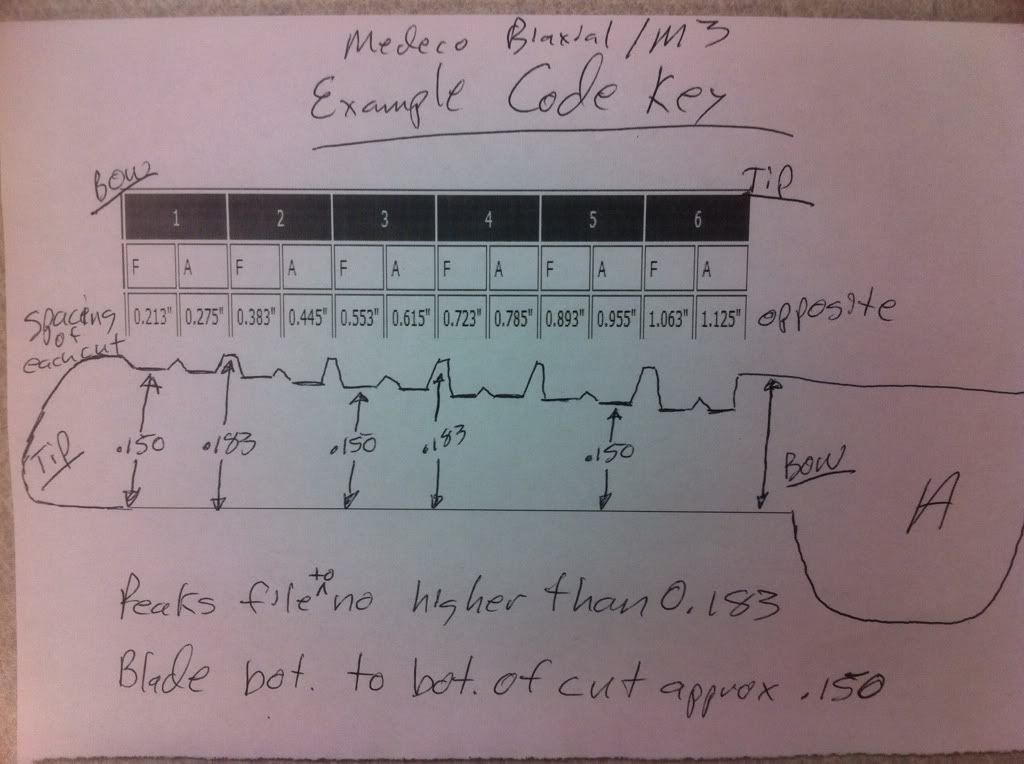

Here is a more organized document I put together to help me when actually cutting the codes so I dont have to think to much when doing it, I have two references for medeco cuts at the top, which is accurate they are both different for biaxial and M3

article is here http://db.tt/QBOjMESC

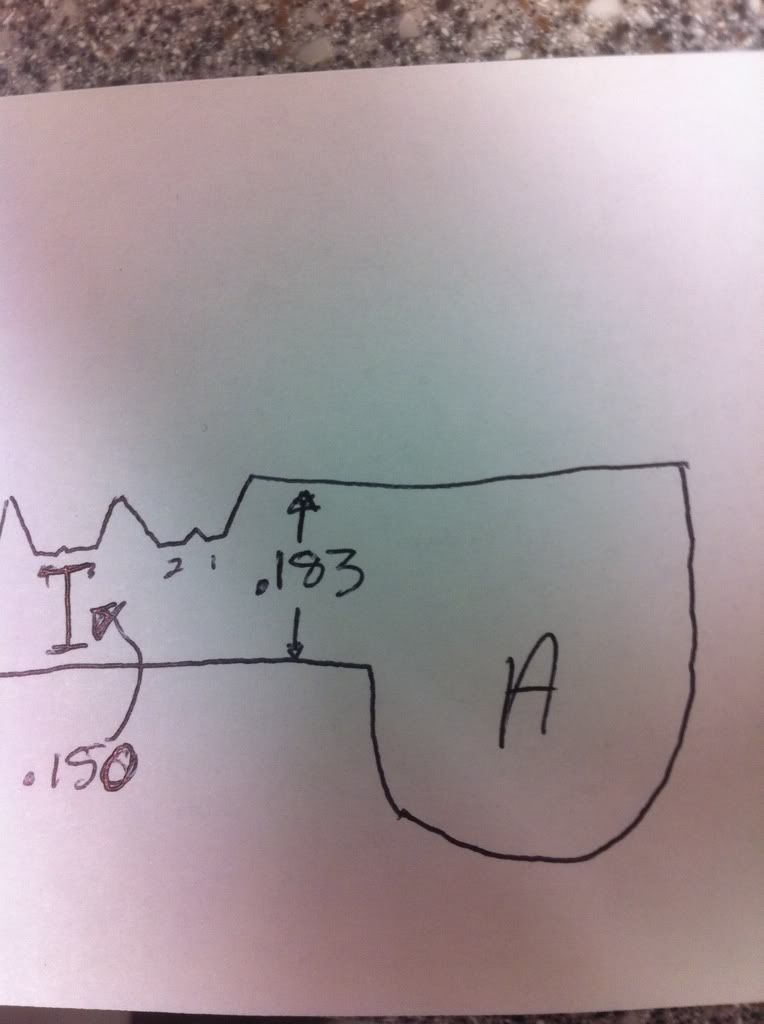

Also if reference is correct a number 6 cut is .142, barbarian says his at bottom of cuts were .150 wouldnt this slightly over set a 6 pin especially when withdrawn when raised by points inbetween cuts any help would be appreciated. im gonna try to get started today and try for a key per day, I only get a 30 min lunch to use the medeco key cutter

I guess I could start at .150 and sand down the base if it doesnt work. Let me know what you guys think.

article is here http://db.tt/QBOjMESC

Also if reference is correct a number 6 cut is .142, barbarian says his at bottom of cuts were .150 wouldnt this slightly over set a 6 pin especially when withdrawn when raised by points inbetween cuts any help would be appreciated. im gonna try to get started today and try for a key per day, I only get a 30 min lunch to use the medeco key cutter

I guess I could start at .150 and sand down the base if it doesnt work. Let me know what you guys think.