Making a Key for a Tubular Brake Pedal Lock

This brake pedal lock with a tubular lock was given to me because the person had no key.

The lock has no center post, so could not find any blanks without ordering them.

Decided that I needed some sort of challenge, so decided to make a key for it. First order of business was to pick it. My tubular lock pick has a center post, so it would not fit into this lock. Rather than remove the center post, just used some music wire tools to pick it. The dog-leg shaped tool is the tension wrench, the other is used to press the pins.

Once it was picked open, found a slight problem... there is a spring return, which automatically returns the cylinder to the locked position. This would not suffice, so there are two solutions to this problem. The first is to turn the lock enough that the next set of driver pins reset the key pins. I wanted the lock in a picked position, but with the key pins not being acted upon by the drivers. This left the next solution:

A safety pin bent to fit in the lock. Pick the lock, and turn it to just before the next set of driver pins catch the key pins. Insert the holder like so and release the tension. The clip will keep the cylinder from rotating back to the starting postion. It looks like this:

Tape the clip in place so it does not pop out, making you restart the process over and over again. Don't ask how I know. Grrrrr.

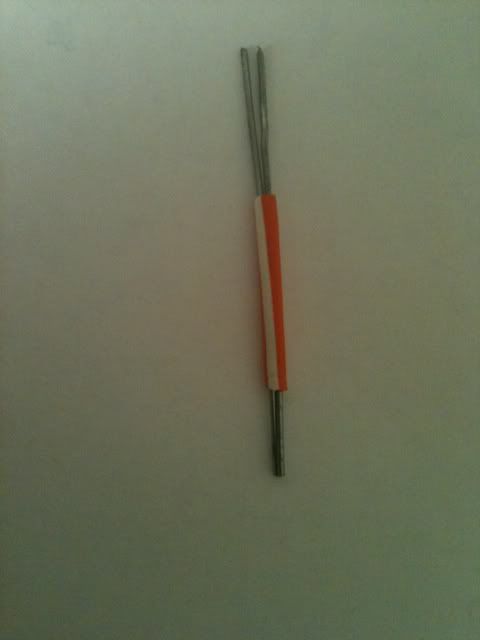

The next high tech tool needed:

The tool is made from two straight pieces of paper clip pressed through a short piece of wire insulation. This is for reading the pin depths. As important as it may seem, the color of the wire insulation does not really make a difference.

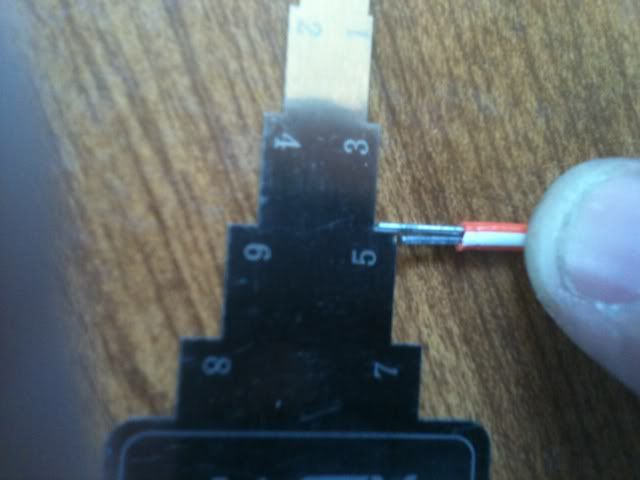

With the lock in a picked postion without the driver pins acting on the key pins, the tool can be used to find the depth of the pins by having one piece of paper clip on the top of the key pin, and the other is allowed to be pressed to the bottom of the keyway.

If you have a tubular lock key gauge, hold the tool up to read the bitting depth:

The wires actually are flush with the gauge at 5, but the bevel on the end of the wires from the wire cutters make it look like they are not. I could file the wire ends to make pictures better, but not worried about it.

If you do not have a gauge, then just hold the tool up to your blank and mark the depth to which you will cut the key bitting. This is just brass tubing that I had, as I could not find key blanks quickly enough for my desire to make a key.

The brass tubing was big enough to fit around the center post of the lock cylinder, but the walls were too narrow to even touch the key pins. I used a socket which I tapped into the end of the tubing to swage it larger, so it would easily contact all the key pins. Used a dremel tool to cut the bitting into the key, then a slot in the other end. Flattened another piece of tubing and brazed it into place as a key bow. Ugly, but works as well as a new factory key.

Just a note: The drive posts in the key are not really needed in a tubular lock. If the key pins are at the shear line, you can use the key pins themselves to drive the plug.

Hope this gives some of you some ideas. I just hope those ideas do not entail beating me senseless.

Gordon