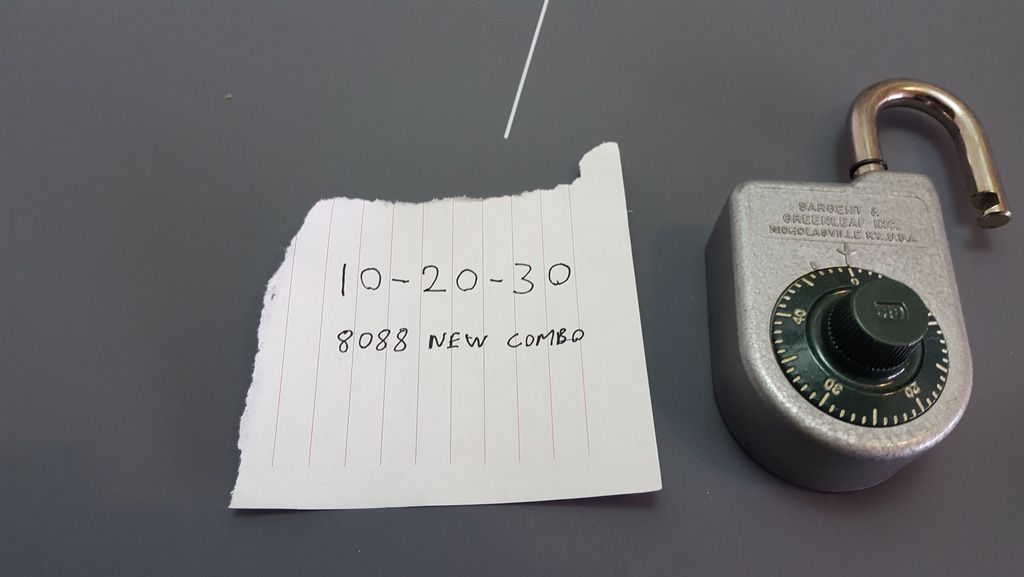

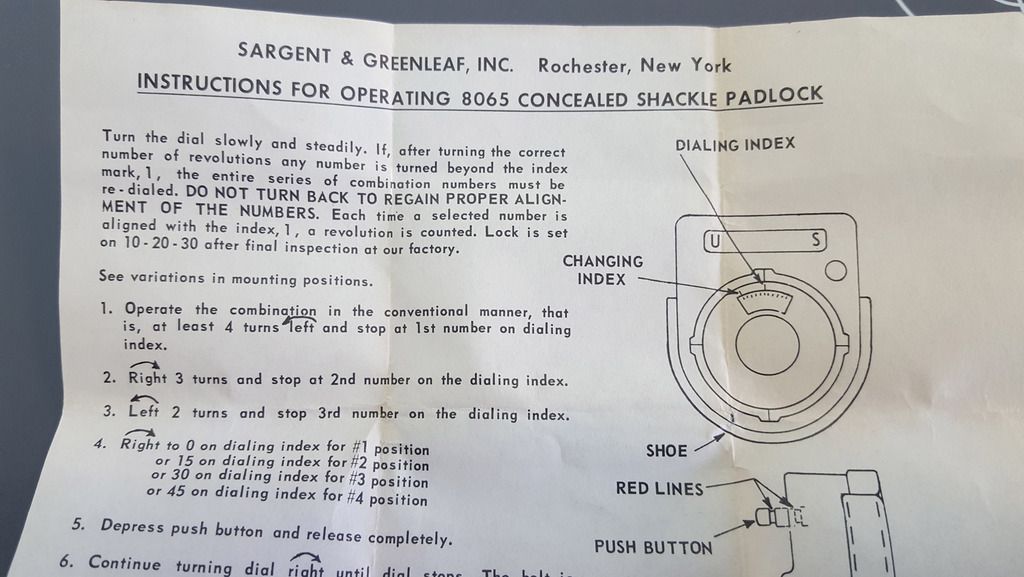

Let’s kick off the final phase of new updates with a

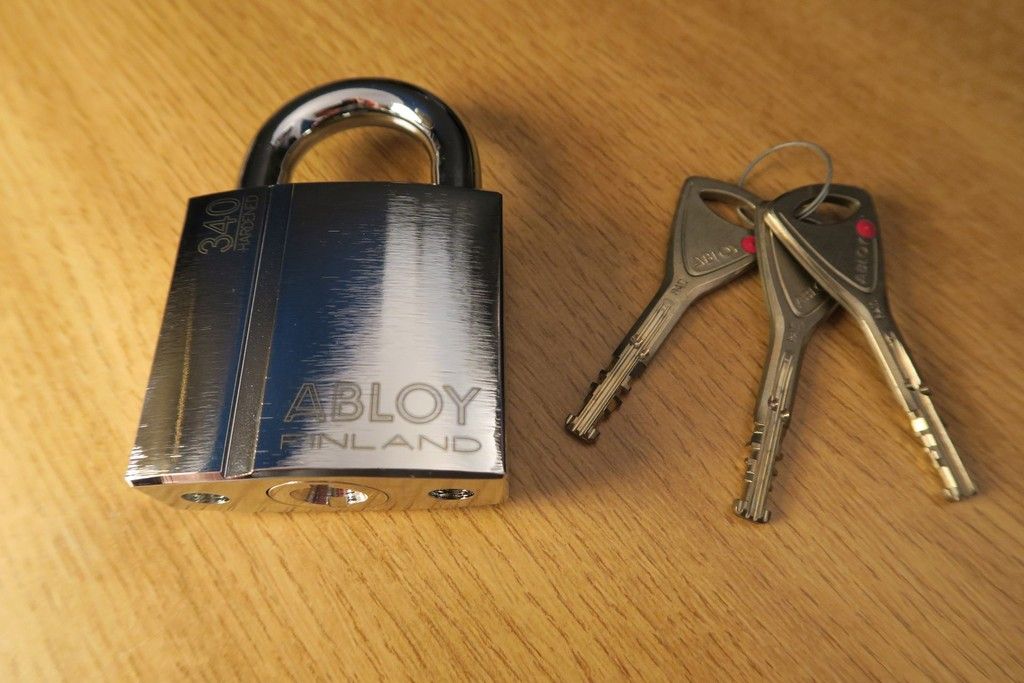

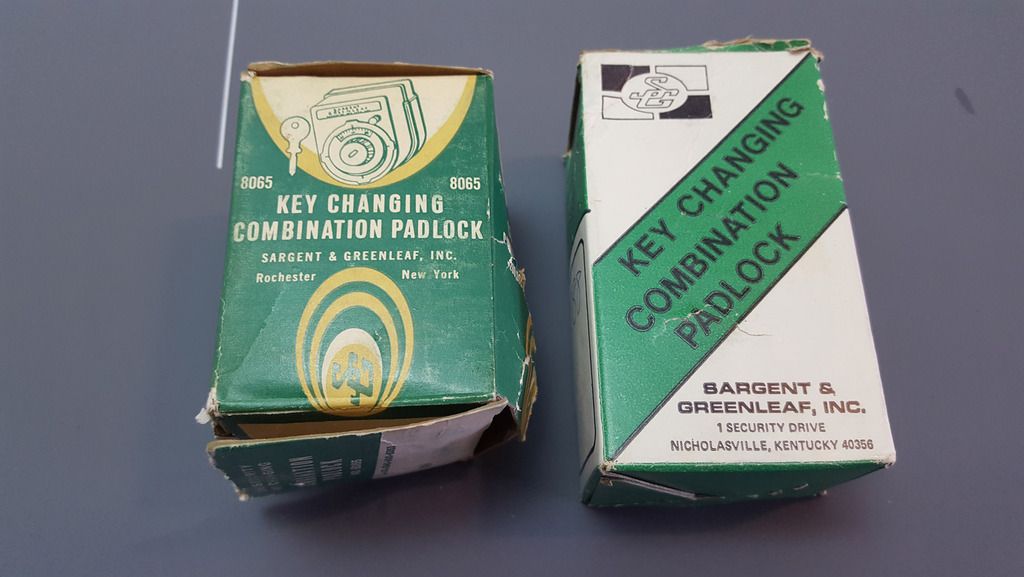

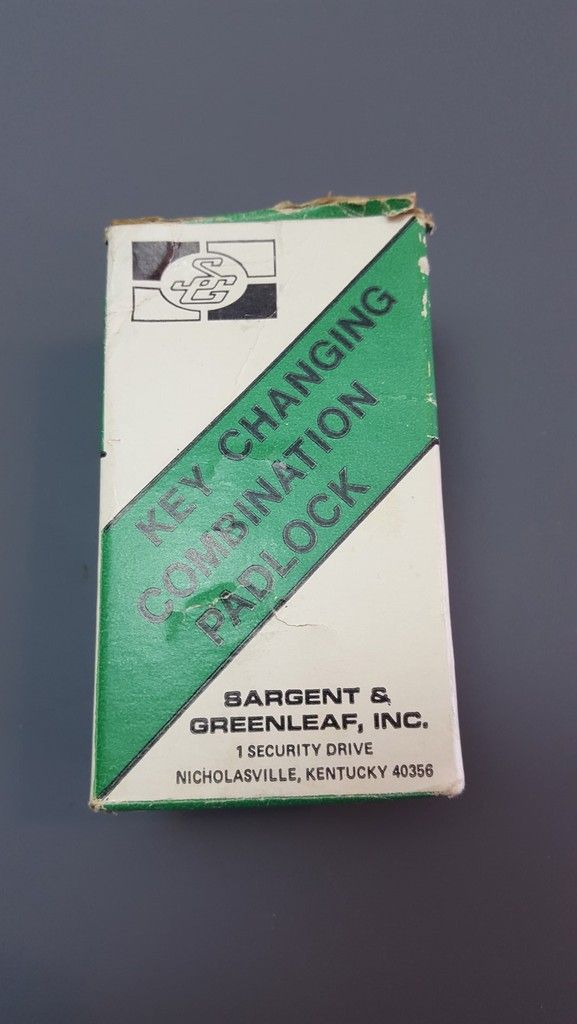

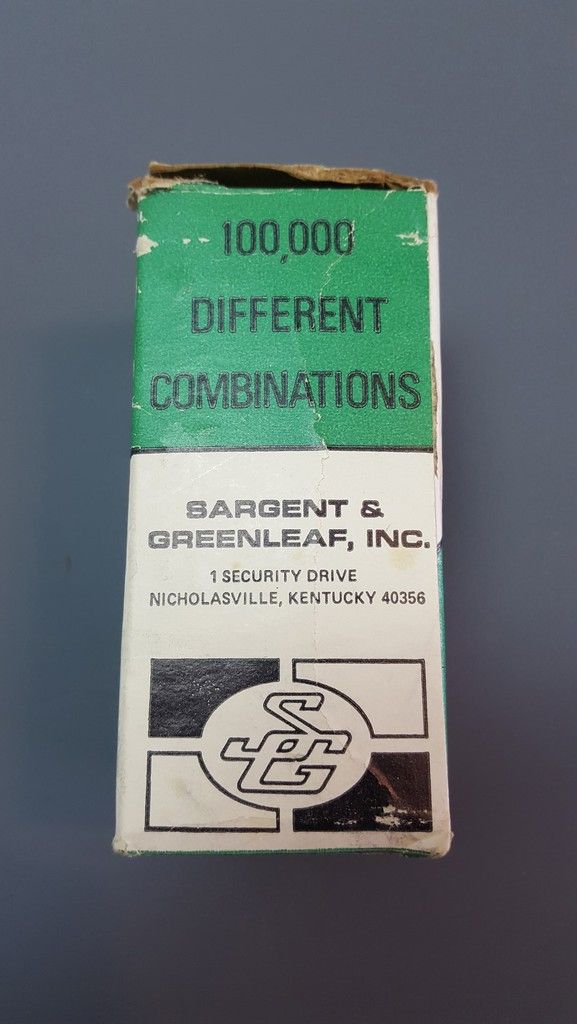

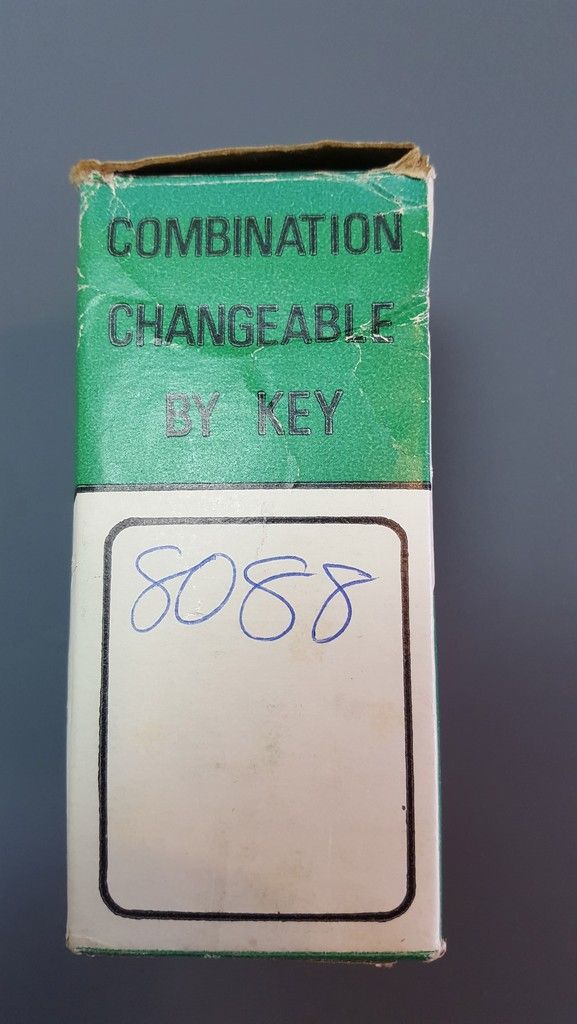

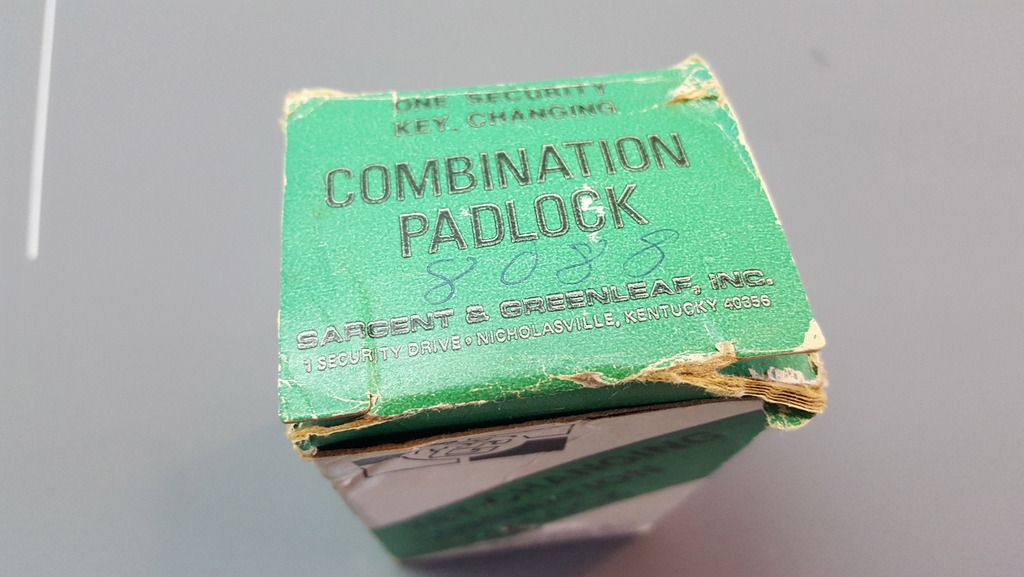

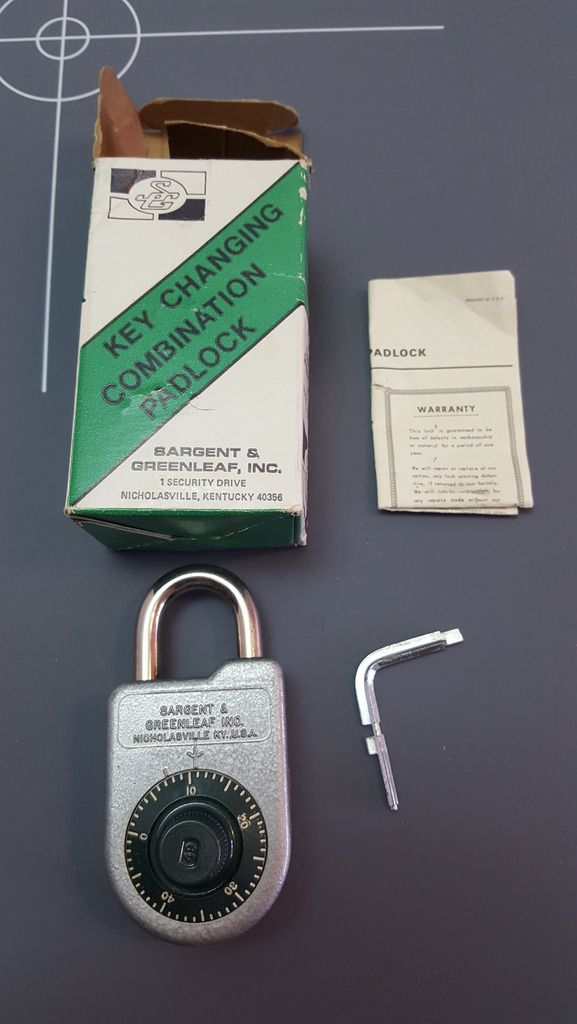

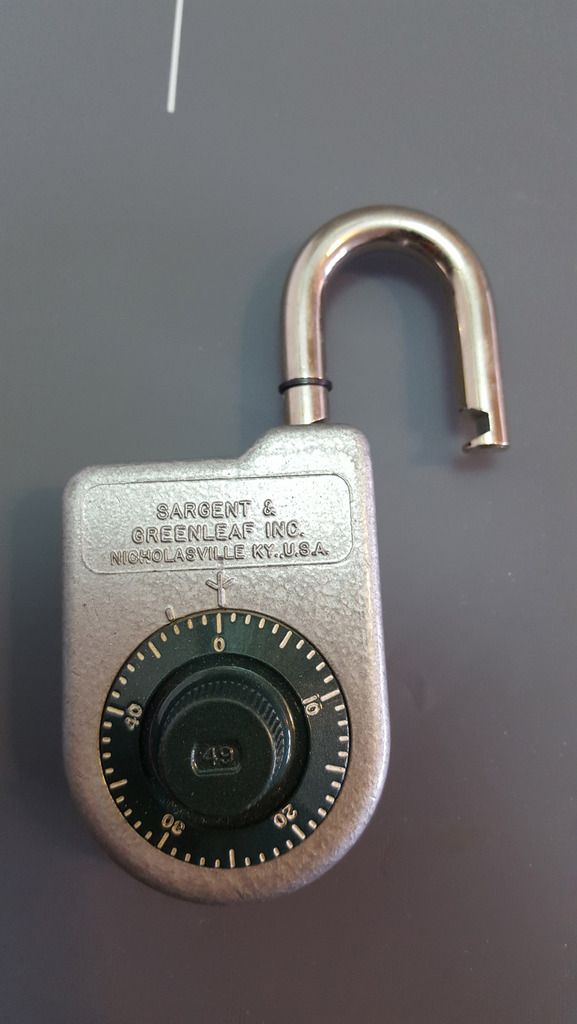

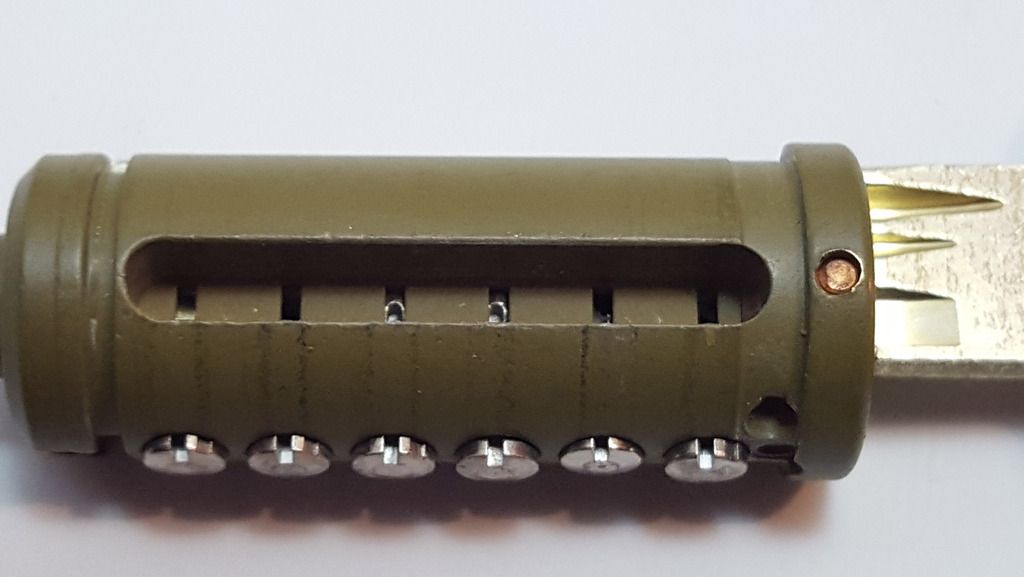

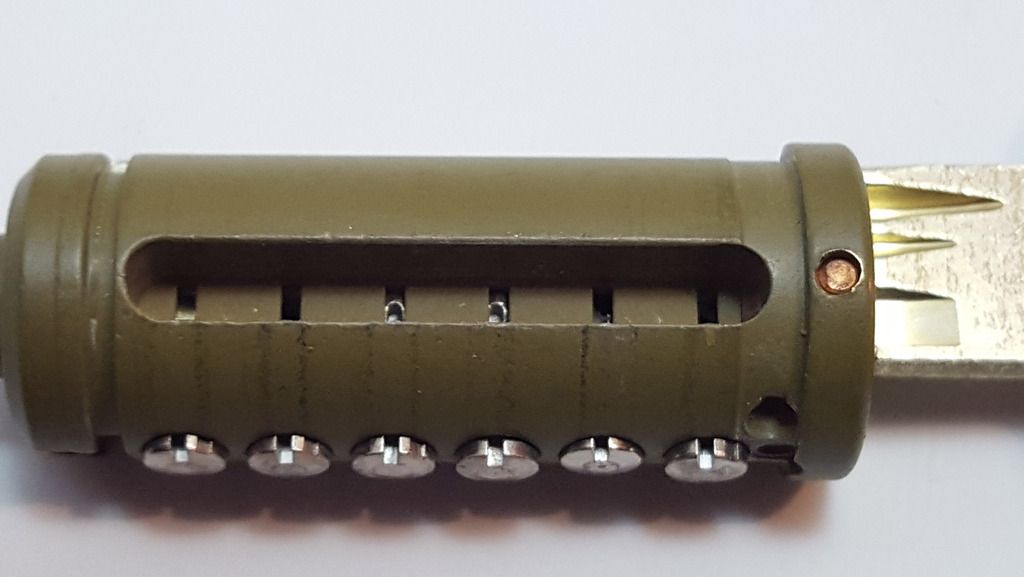

Sargent & Greenleaf 833:

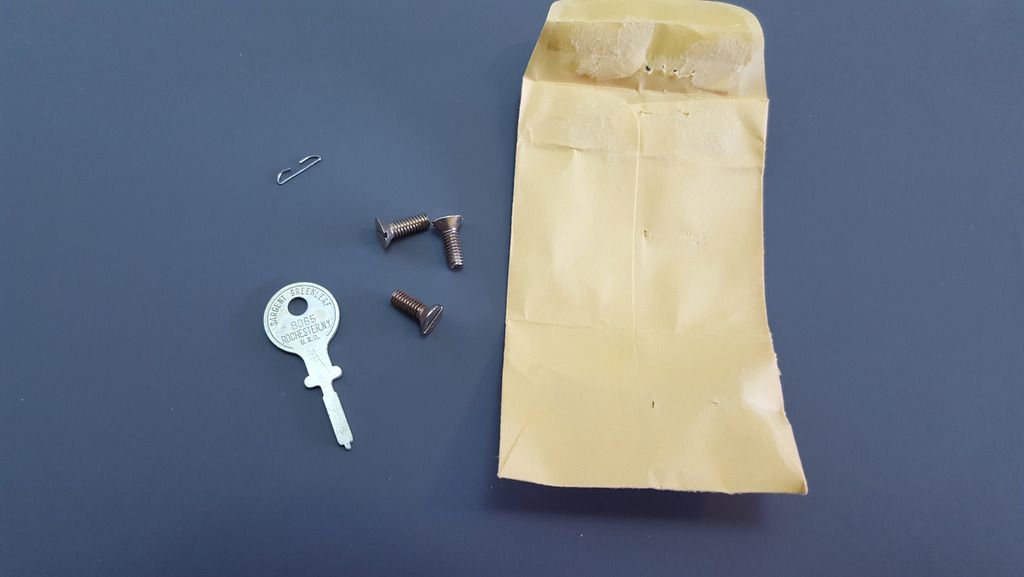

This one came from a forum member and is not in its box but it does come with all three original keys and the keycard. These S&G locks (Medeco cylinders) come with two operator’s keys – the ones with the round bow – which are purely for locking and unlocking the lock, and they also come with a control key – the square bow one – which, as well as locking and unlocking the lock, will also allow the lock to be disassembled for servicing and to change the core or parts inside. Interestingly the difference between the two types of keys isn’t in the bitting at all – both keys are cut identically – but (depending on the exact model) is usually just a small cutout or notch near the bow of the key, on the reverse side to the bitting, or a shoulder vs not-a-shoulder in the same place. This does mean that you can usually modify an operator’s key into a control key, if you wish.

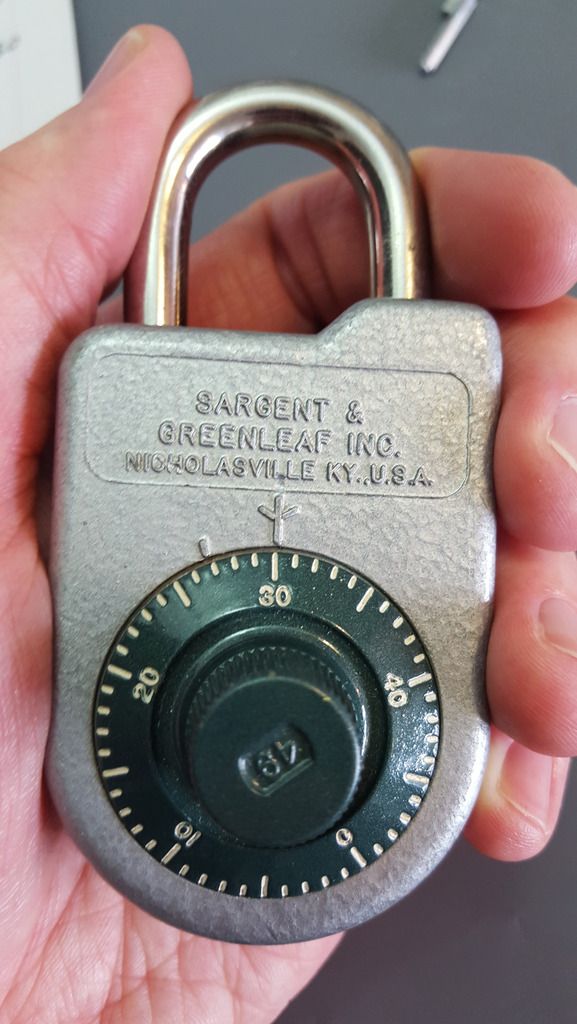

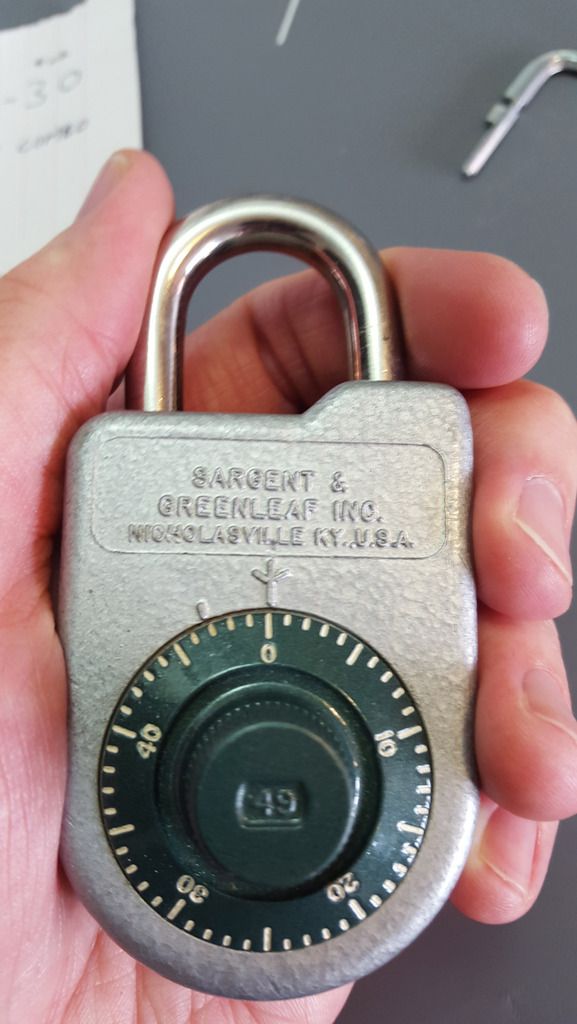

The S&G 831, 833, and 951 (the chronological successors of the series) are super heavy duty, weigh a tonne (around 2.2kg or so each) and are resistant to everything from cutting and drilling to exotic liquid nitrogen attacks. I believe they’re usually used on ammunition bunkers and the like, although you can buy them for civilian use such as high security installations.

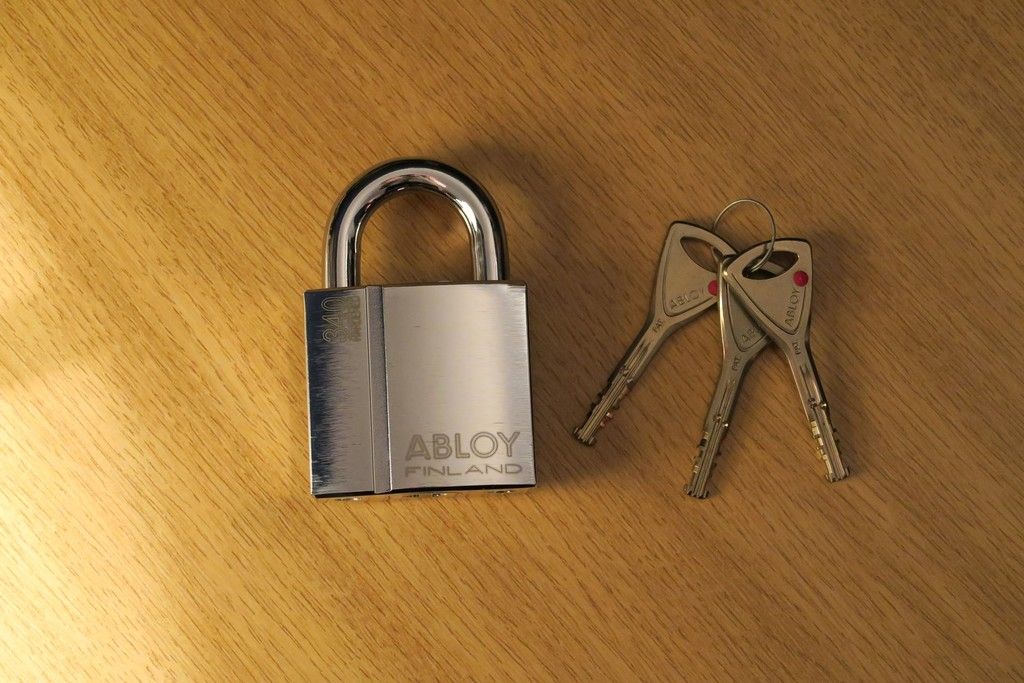

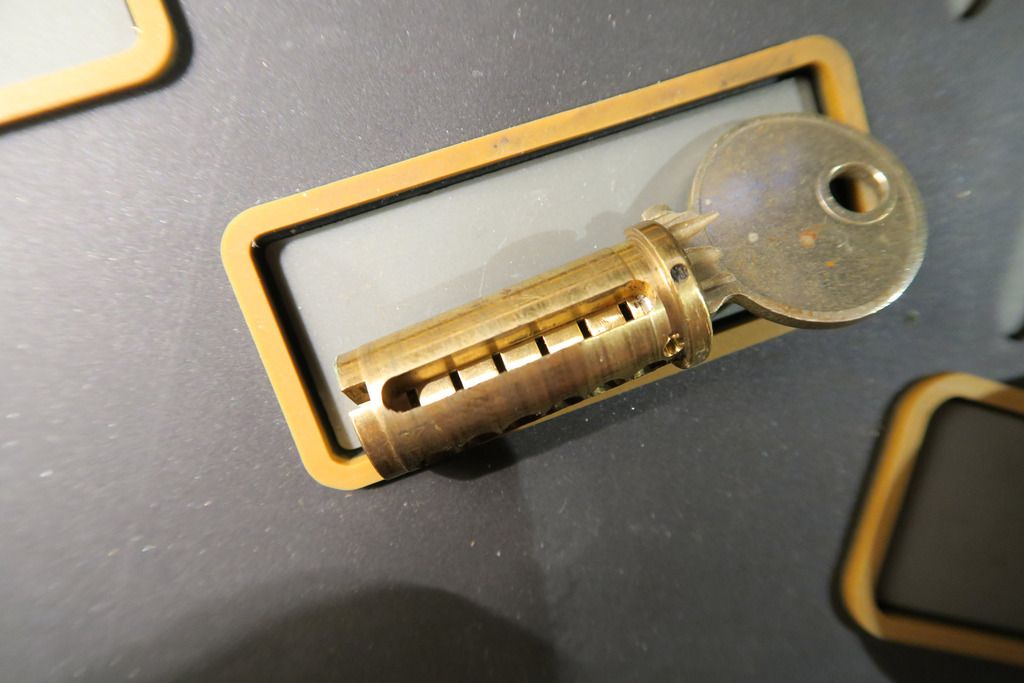

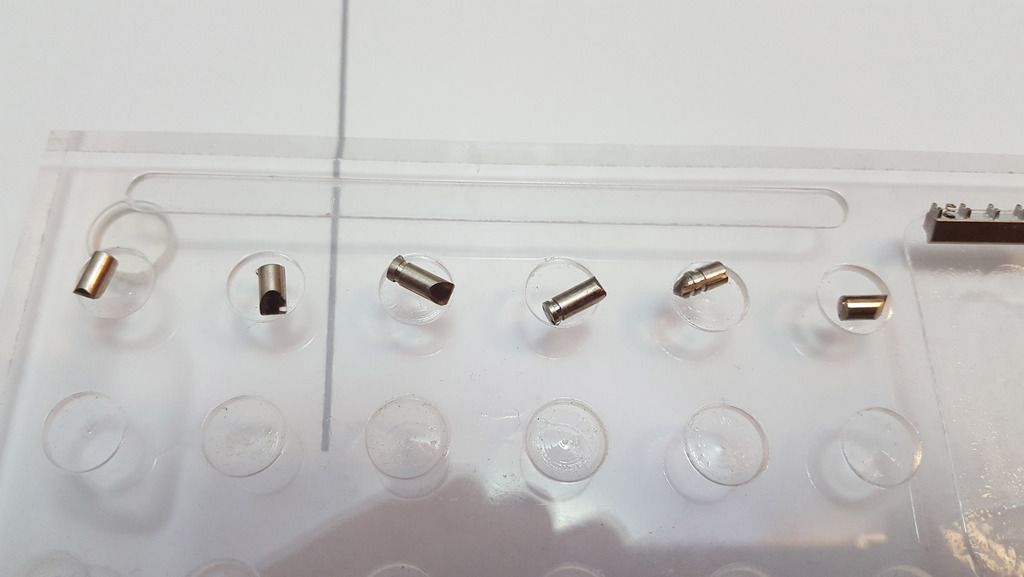

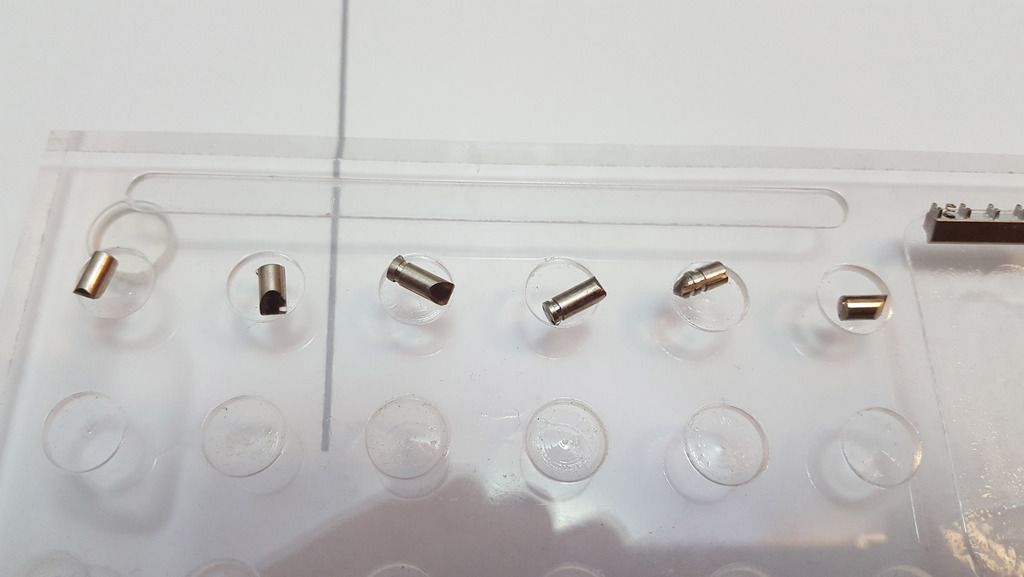

Close-up of the keys:

It is typical, in my experience, for the control key to be on a separate keyring to the operator’s keys – along with the code card. It is, after all, designed to be kept separately and given only to authorised personnel. These are 6-pin Medeco cylinders although I have been unable to ascertain which key profile these are (e.g. classic, Biaxial, M3 etc) or which keyway types they are (R1, D4, S1 etc). Nice shiny keys!

Back of the beast (or front? I’m not sure what counts as the front and the back tbh):

It’s a little scratched and beat up but still works perfectly – that’s solid, precision engineering for you!

The side, also a bit dinged:

Top of the lock:

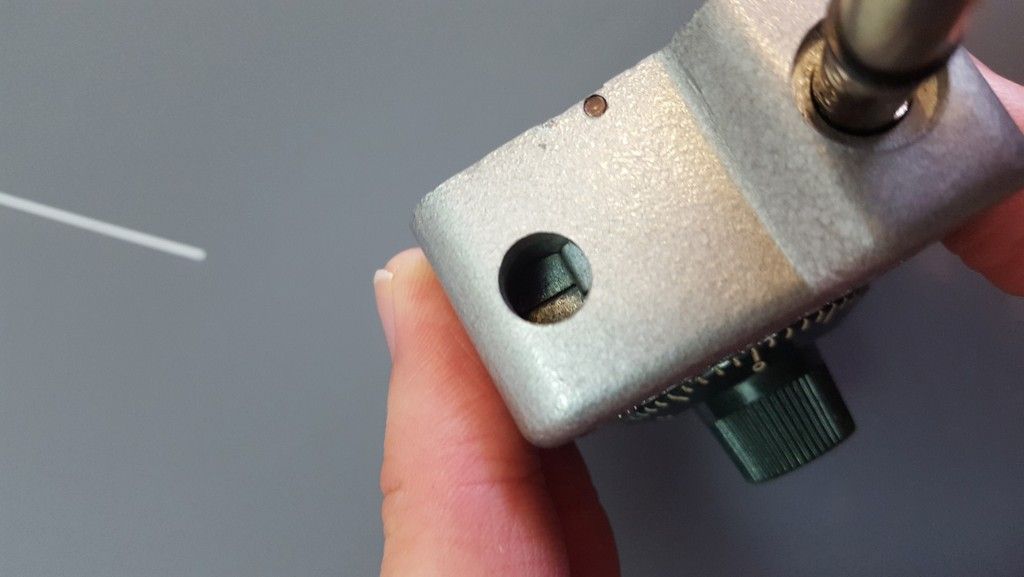

Bottom, where you can find the keyhole, drain hole, and my personal nemesis due to its prevention of the lock being freestanding, the chain anchor. The oddly shaped keyhole cutout is due to the way the operator and control key works.

To see what I mean, take a look at the following photo. The operator key is inserted. Notice how the protrusion (shoulder) on the back of the key prevents it from turning past that block off point? It can rotate clockwise but not anti-clockwise. That’s the direction to open the lock, whereas the control key, which does not have a shoulder, can clear that obstruction and turn anti-clockwise too, allowing it to turn the actuator to a position where the lock can be opened.

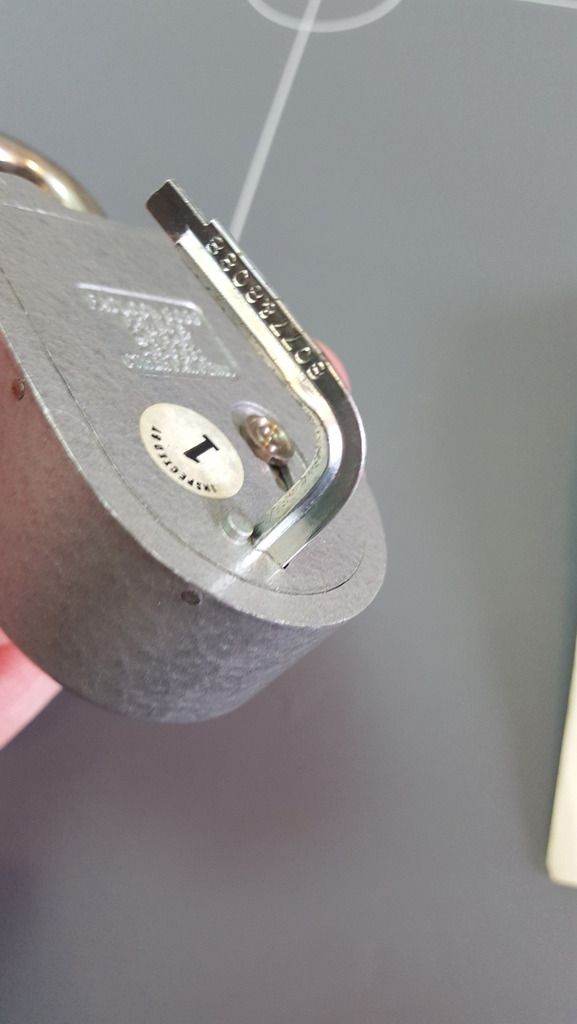

Shackle is a little dirty:

Turned to the opening position, the shackle can be freed and swung open. It’s closed shackle and key retaining, and the shackle can only “exit” the body in one direction. Also note the big “seam” in the middle of the lock that makes it look like the body is made from two pieces...

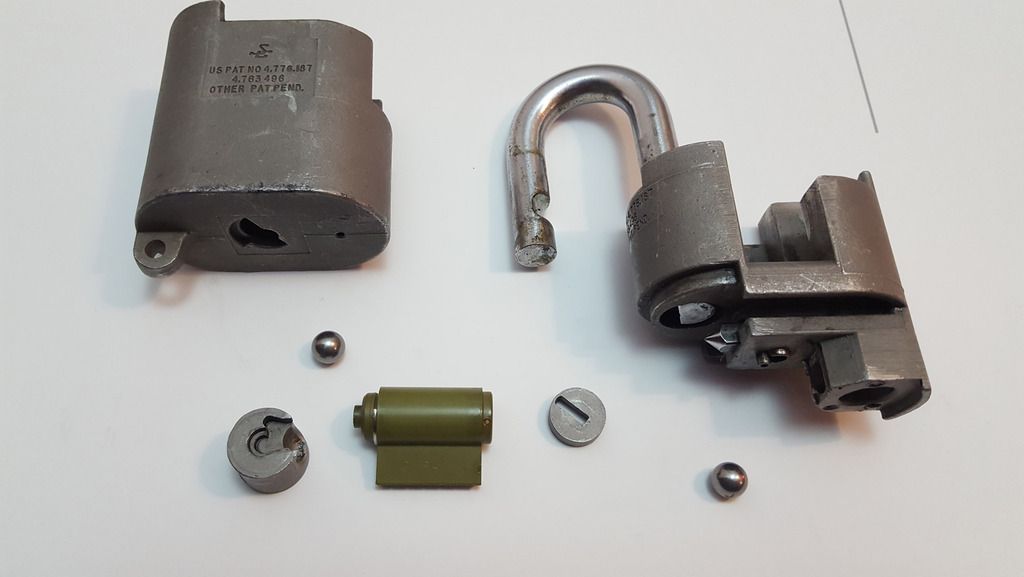

With the control key inserted and rotated in the opposite direction, the two halves of the lock body slide apart and the lock can be stripped and serviced. Watch out for escaping ball bearings!

Side of the body. There’s supposed to be an anti-drill ceramic rod in that cutout slot, but it’s missing unfortunately:

View inside the bottom half of the body. From front to back: first we see that large round silver looking disk recessed into the body. I believe that’s a continuation of the shackle, or at least a plug made from the same stuff, to deter drilling. Back one more component, that grey round plug with the odd notches cut into the top is the actuator that both locks/unlocks the lock, and changes the lock from open-only to control key mode. The notch cut into the top is exclusively for that latter purpose. At the very back is the shackle hole.

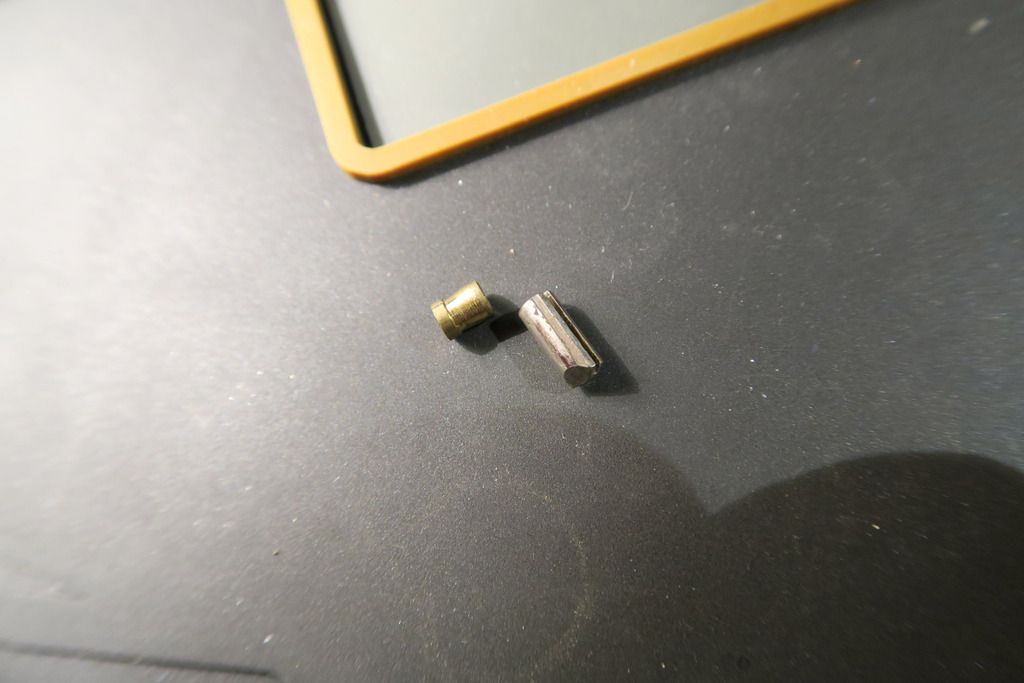

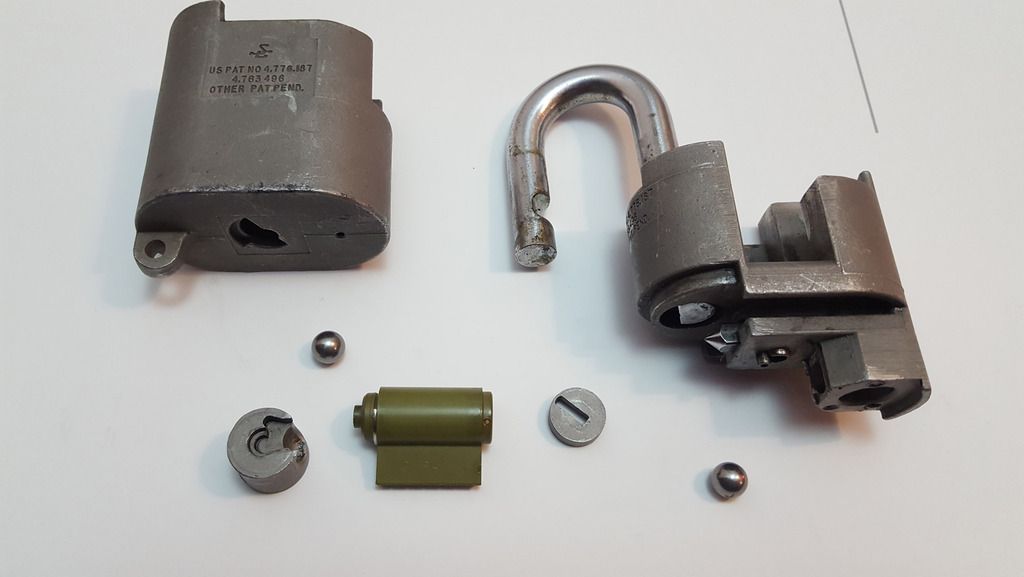

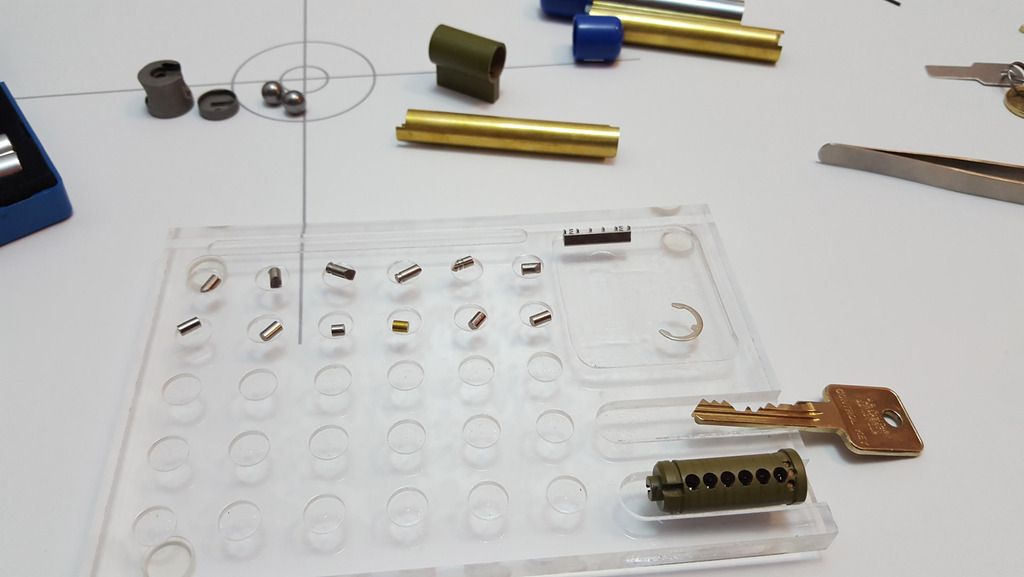

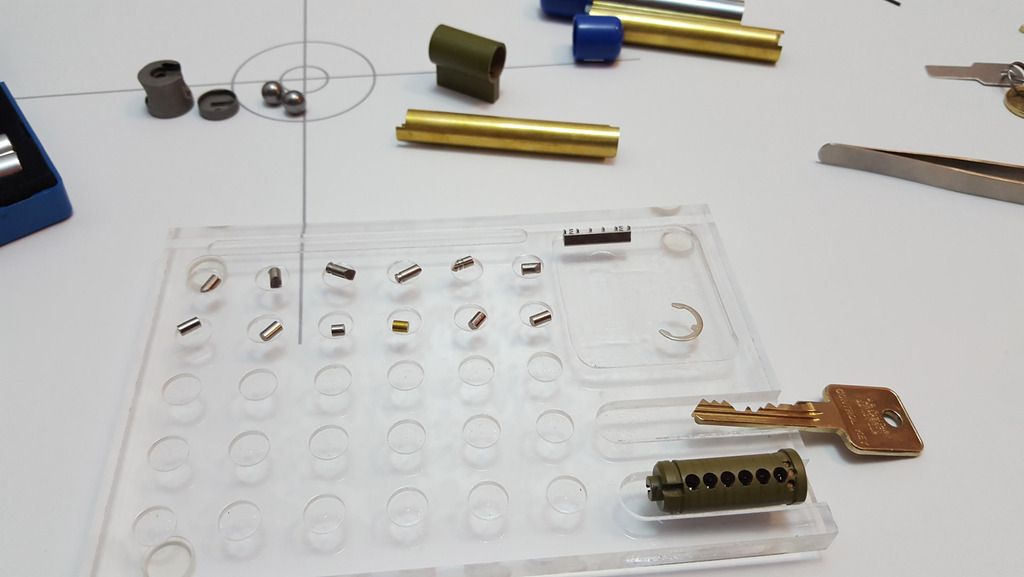

I’ve heard somewhere that military things should not strip down into more than seven basic components, as it’s easy for masses of parts to get lost. I’m not sure if this is true, but S&G military padlocks certainly strip down into less than 7 basic parts. Here we see the two body halves, the actuator (far left), the lock cylinder (green thing in the middle), two locking ball bearings and an anti-drill plate which sits in front of the cylinder:

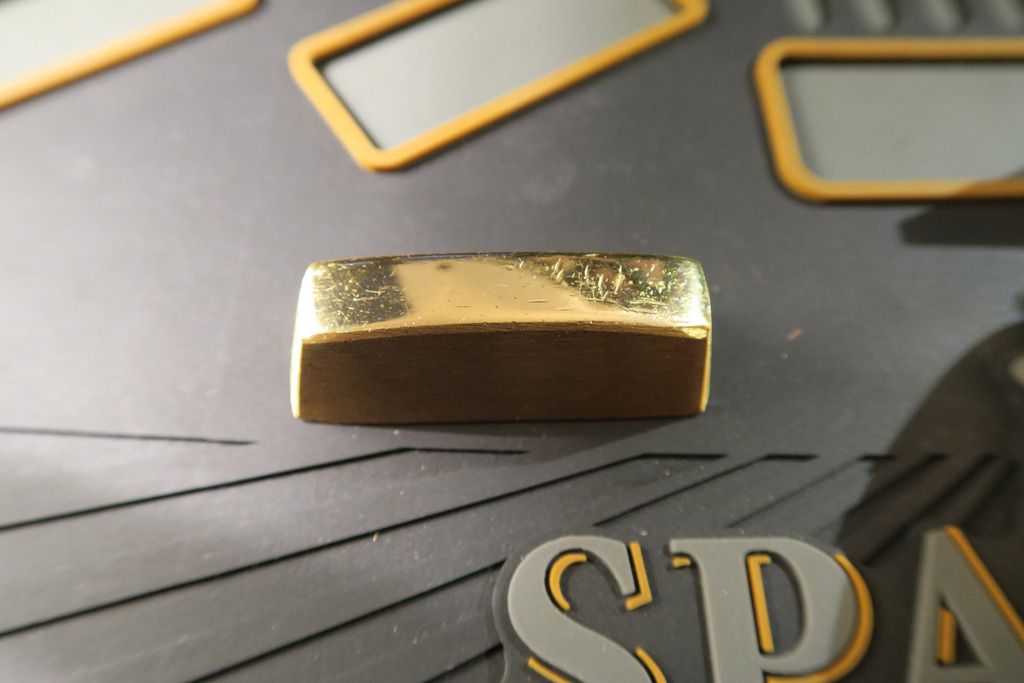

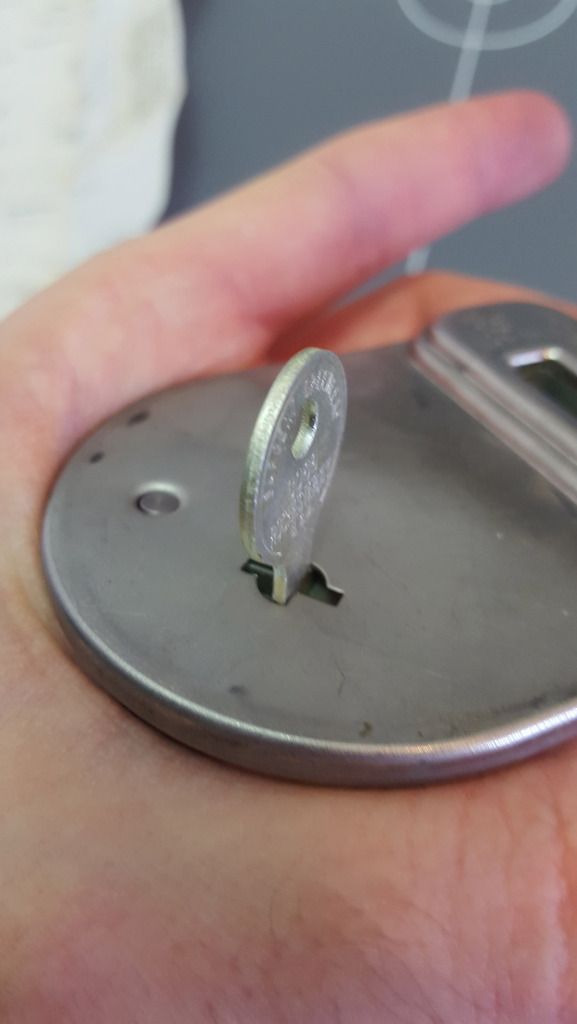

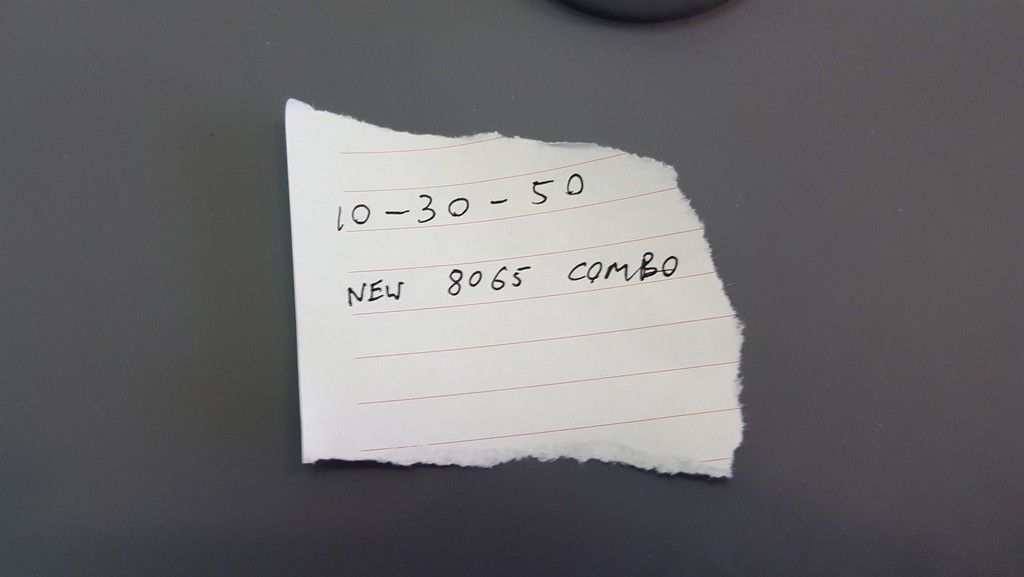

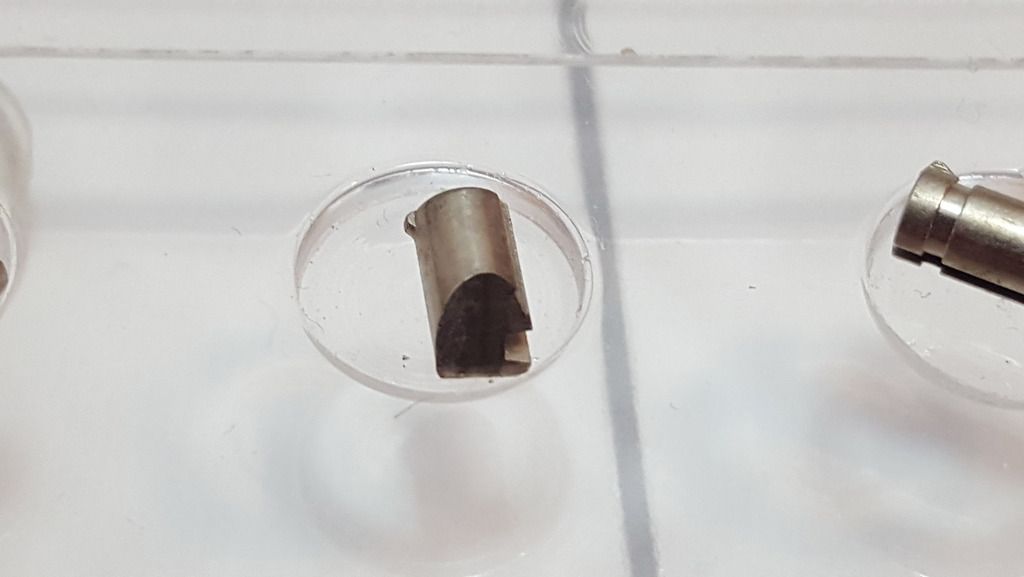

Here’s a closeup of that anti-drill plate. It has a small flat edge which fits with a complimentary edge on the cylinder, so that it sits correctly with the “mouth” over the keyhole. It also has a number stamped into it – in this case, “5” – which can be anywhere from 1-0. The purpose of this, and other UIDs stamped into the lock body, is to prevent surreptitious entry where a destructive attack is made on the lock, the pins decoded and then an identical and identically-pinned lock is made after getting keys cut or accessing the stock/secrets/whatever that the lock protects. The attacker will not only have to replace the lock, but figure out the correct number for the parts that were destroyed and replace the lock with identically numbered parts. A nifty solution to such a concern!

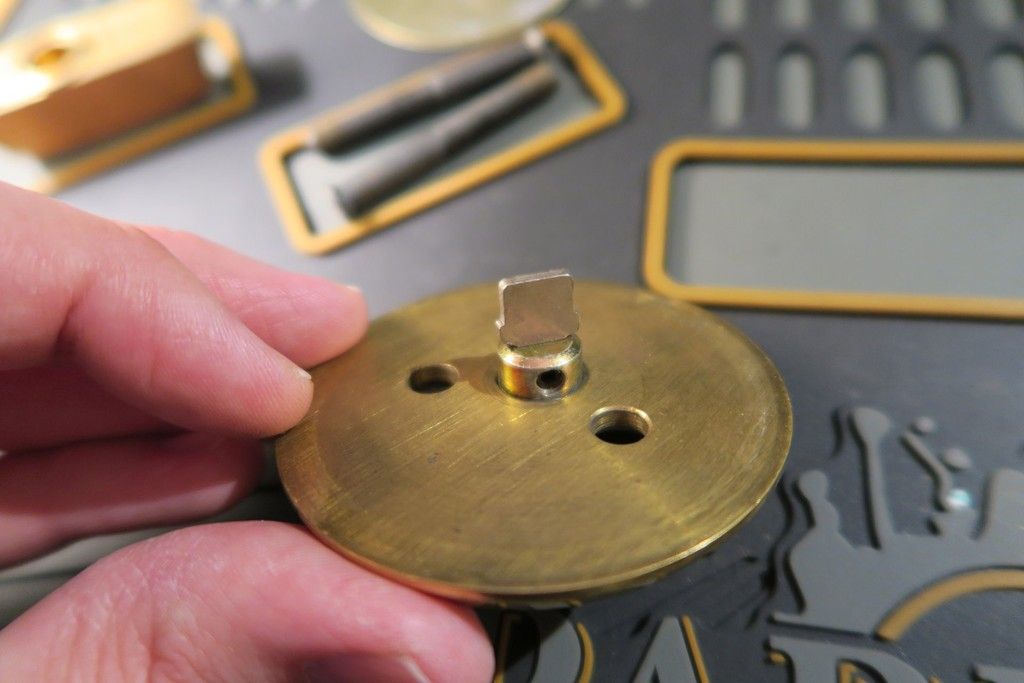

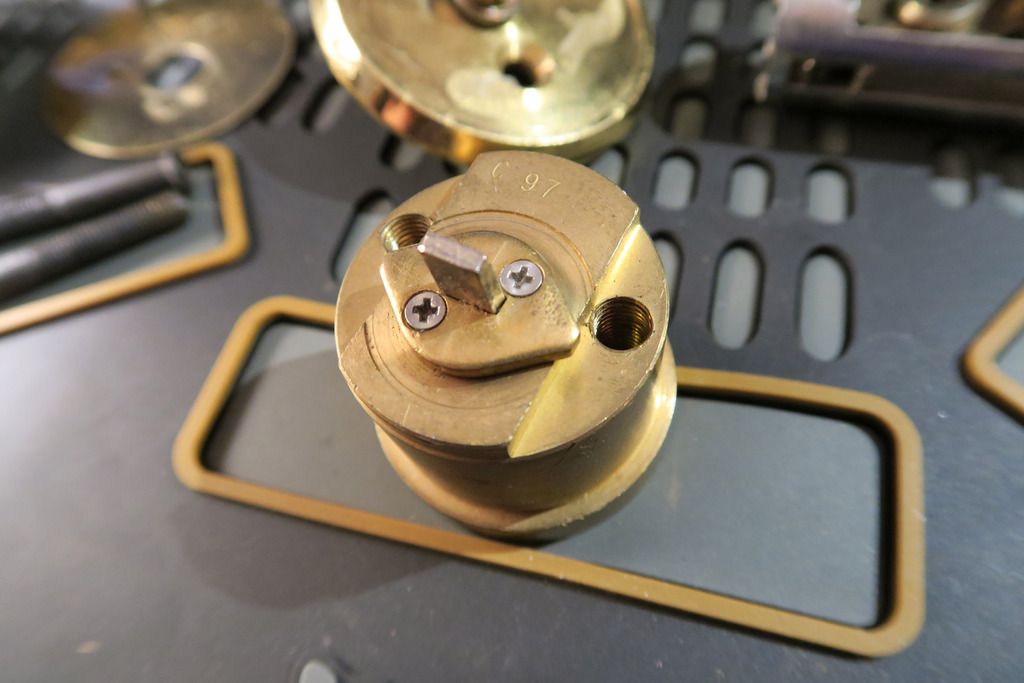

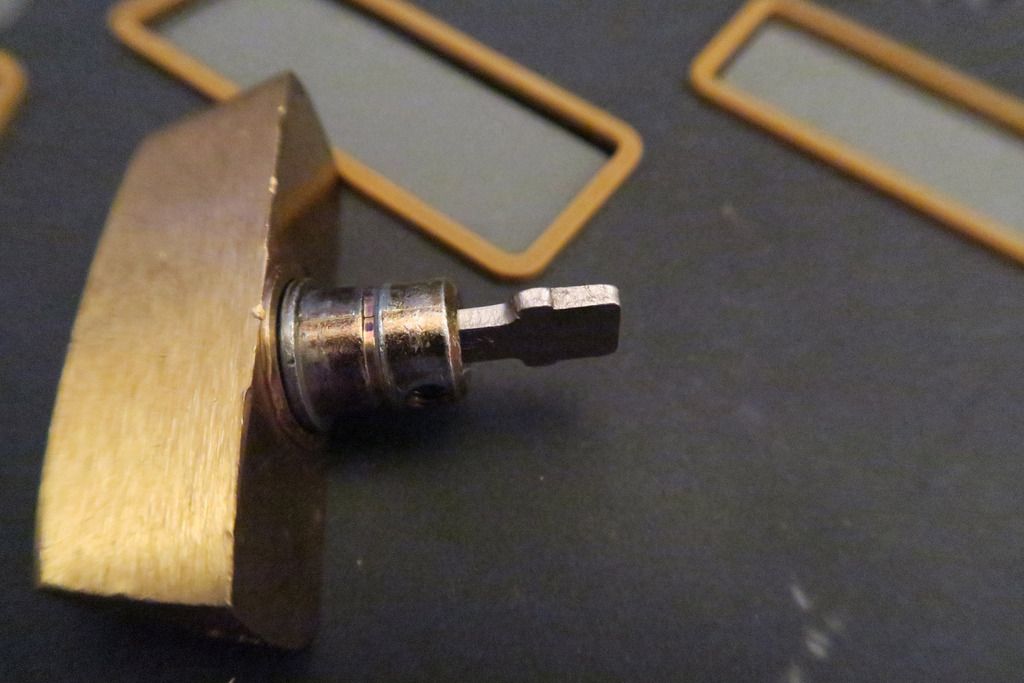

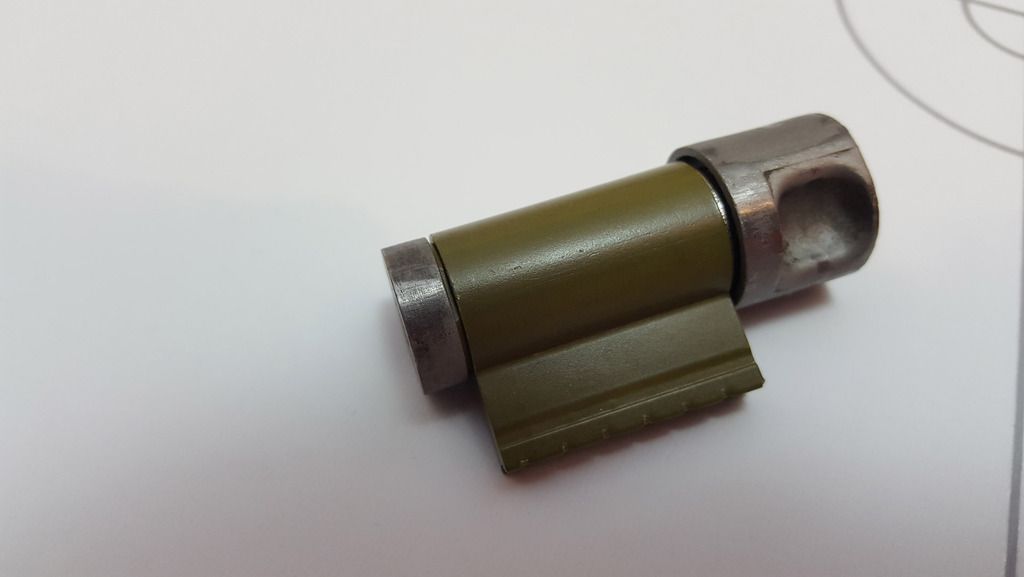

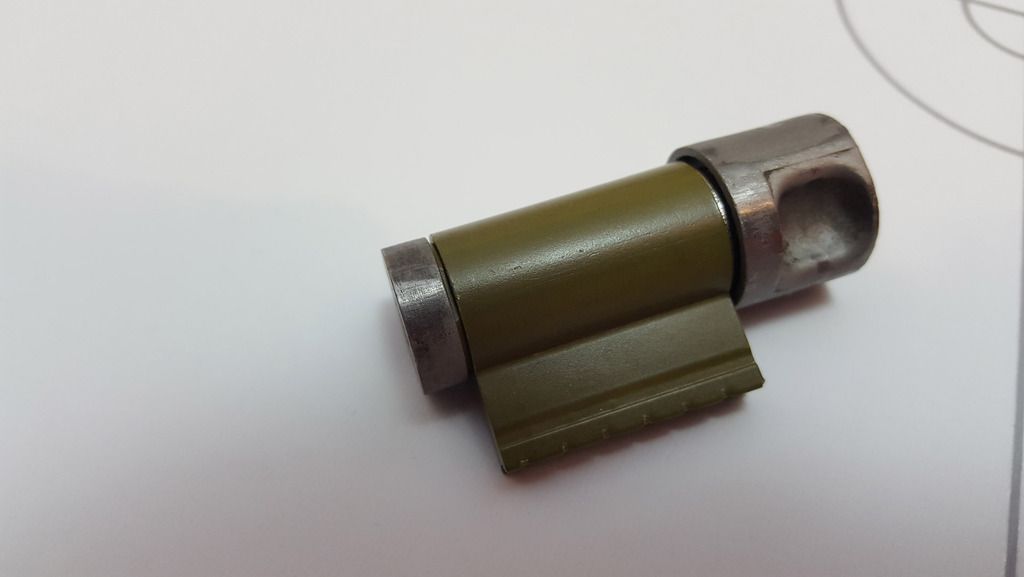

Here’s a closeup of the actuator. It’s a bit grubby at the moment! The cutouts in the top match a pin which sits proud on the top half of the body – when the key is turned to the control position, the pin is able to slide out of this cutout and the lock can be taken apart. The bit hole lower down is for a BB to sit.

Underside of the actuator. The little nub fits into a notch on the cylinder to hold it in place. Note that this part also has a unique number – “2” in this case.

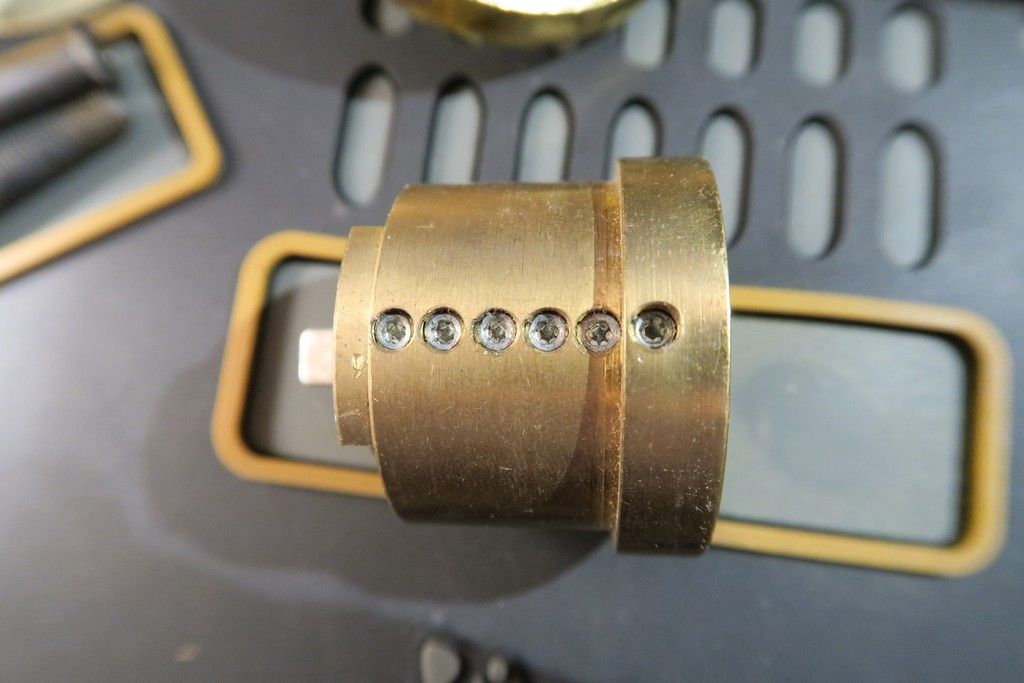

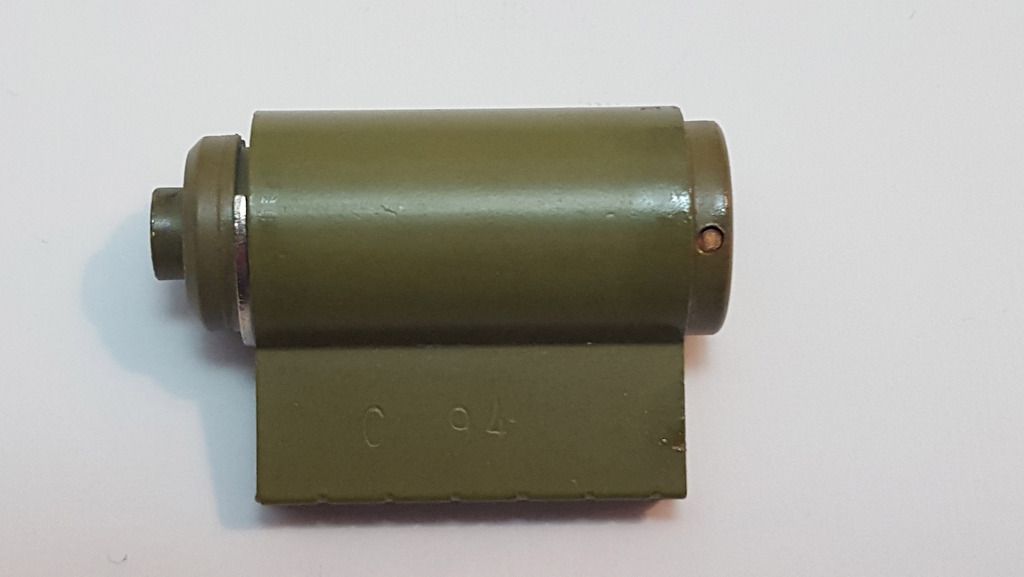

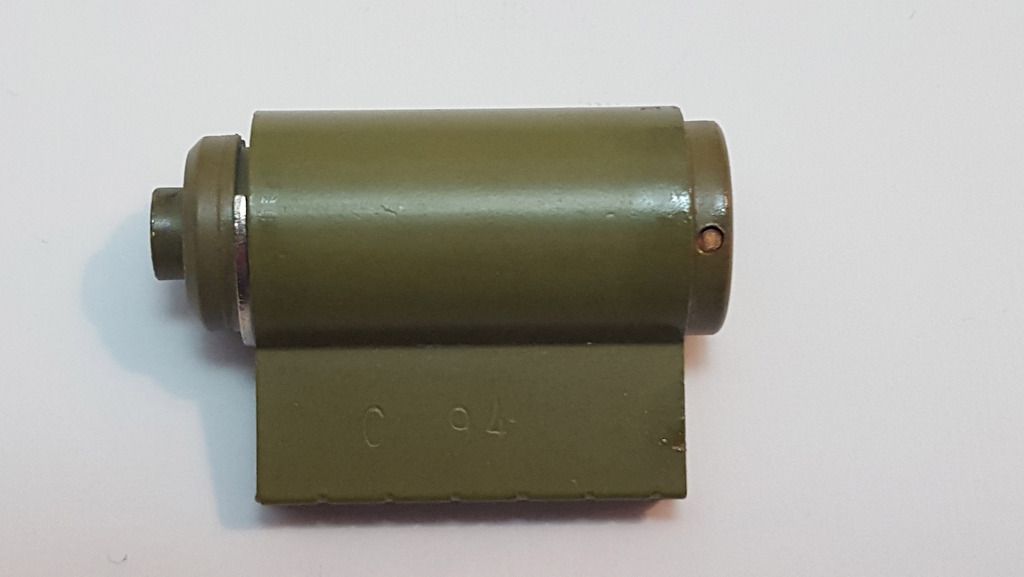

The cylinder! This is a Medeco Military cylinder (AFAIK the cylinders in green Teflon are military and the non-green (I believe brass) ones are civilian – however there exceptions to the rule, especially the older generation of S&G locks which tended to have brass Medeco cylinders regardless. This may have something to do with the newer ones being Biaxial, but I have yet to figure out the specifics):

The back of the cylinder. You can see the notch which fits with the nub on the actuator, and it also a convenient fitting point for the C-clip nub:

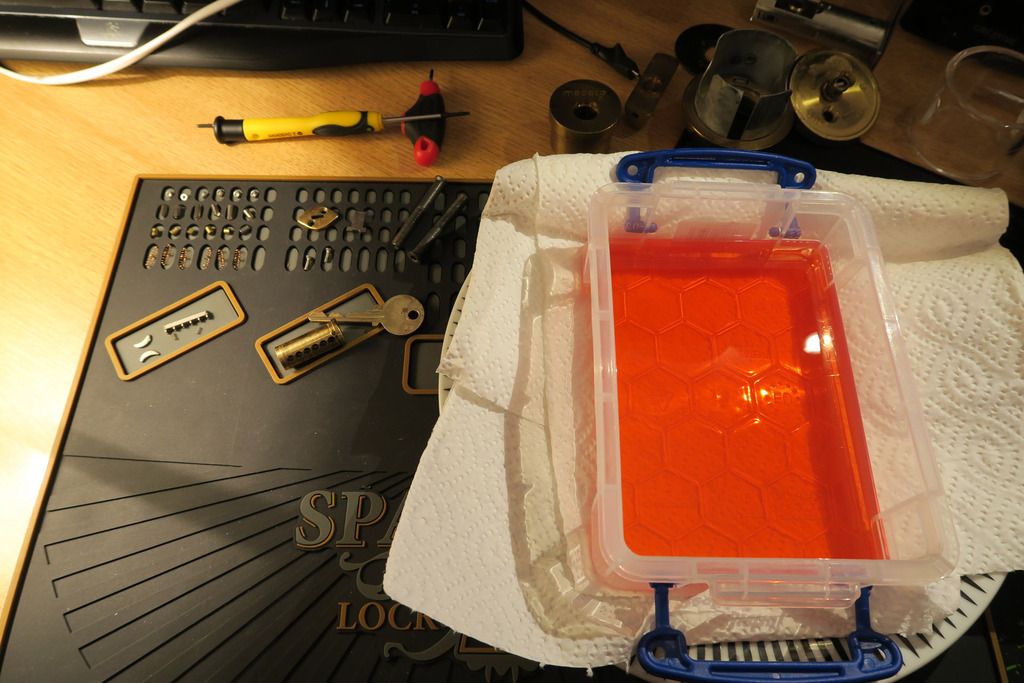

Let’s strip the cylinder!

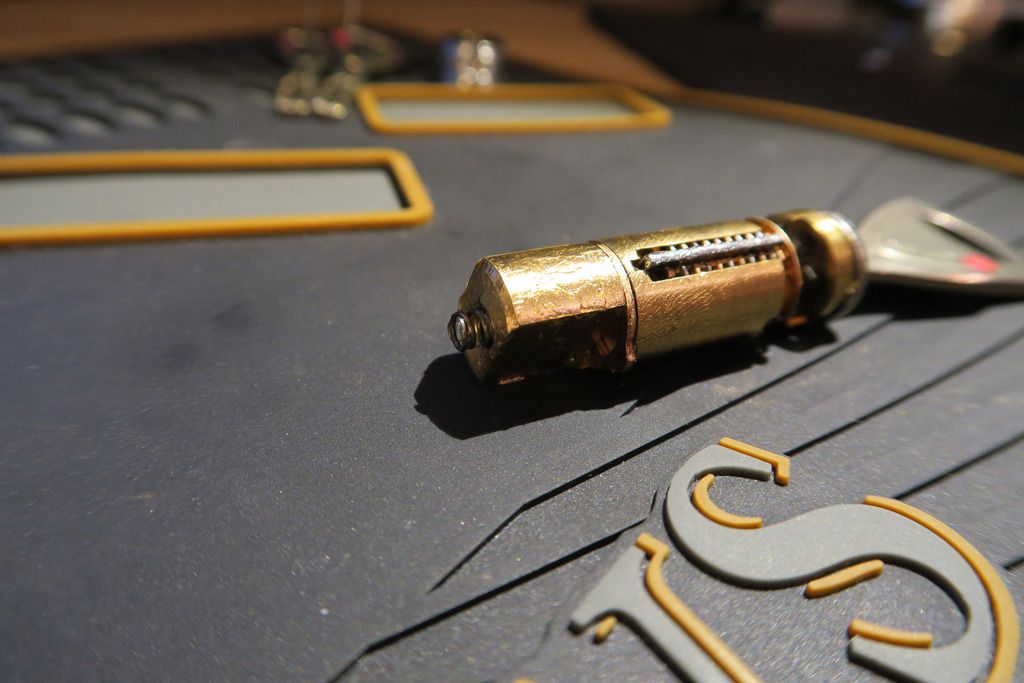

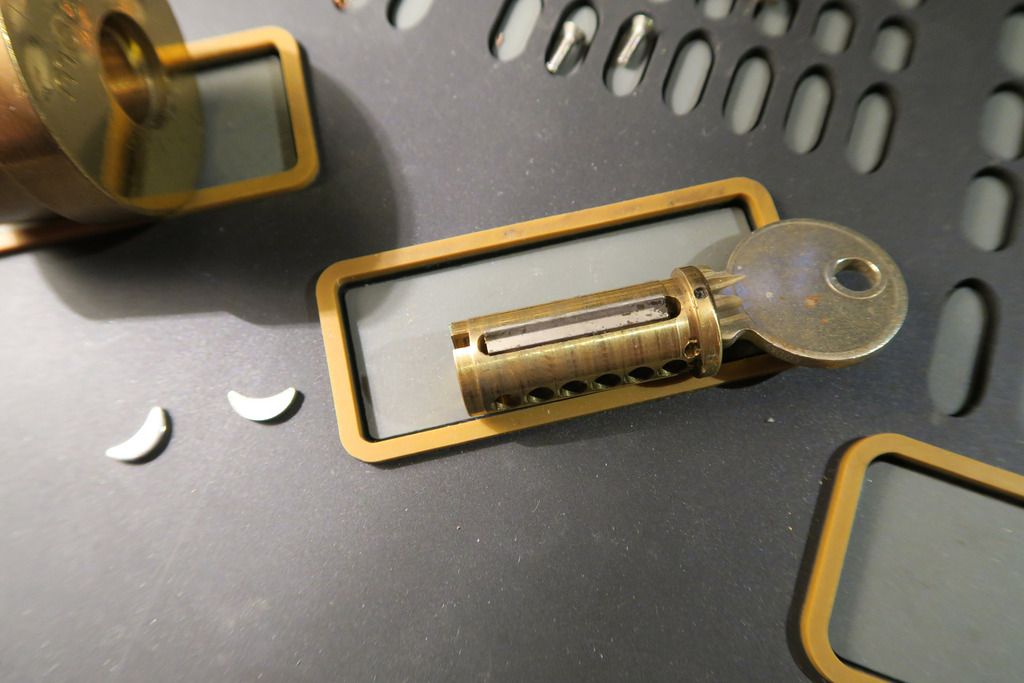

Closeup of the plug:

First off, note the three brass-looking anti-drill pins near the front / key entry point of the plug. Next, you might notice something odd about the pins, if you aren’t familiar with Medeco pins – they have little holes in. This is to do with the extra layer of security that Medeco locks provide – we’ll look at the specific parts as we go along, but in short, they have a sidebar (a metal rod with nubs sticking out of it) which slots into the side of the cylinder and prevents the rotation of the plug if it’s sticking out. The pins each have a notch cut into the side, and then all the pins are rotated to the correct angle, the nubs in the sidebar can slot smoothly into the side of the pins, the sidebar retracts, and the plug can turn. To rotate the pins, the pins themselves are actually wedge shaped and will sit at a certain angle in the angled cuts on the key. What looks like another cut in the pin, on the opposite side, is a little nub that keeps the pins within a certain degree of rotation – you can see that in the pic above, where there is a long-ish cutout around the bottom of each pin chamber, into which the nub is situated somewhere along that slot.

In the next photo you can see the sidebar. Note the six “legs” which stick into the side of the pins as previously described. The two small springs sit into the two holes and push back on the sidebar when it’s in the side of the plug:

In the next pic, you can see the cutout made in the side of the plug for the sidebar. Note the six little slots made deeper into the sidebar cutout, where the sidebar legs go through and, when the key is inserted correctly, can sit into the slots in the side of the pins. Note also the anti-drill pin on the side near the key, too. Be careful when stripping one of these locks – the added dimension of a spring-loaded sidebar on the side of the cylinder as well as the key pins, whilst taking care of getting the plug follower in at the right angle can lead to a pinsplosion disaster

.

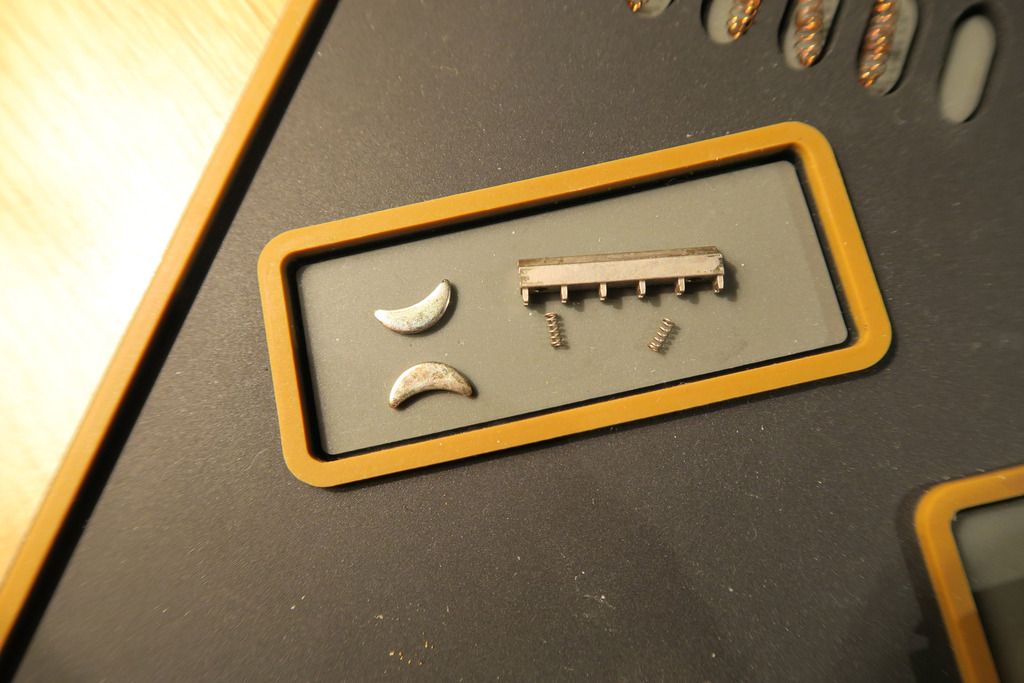

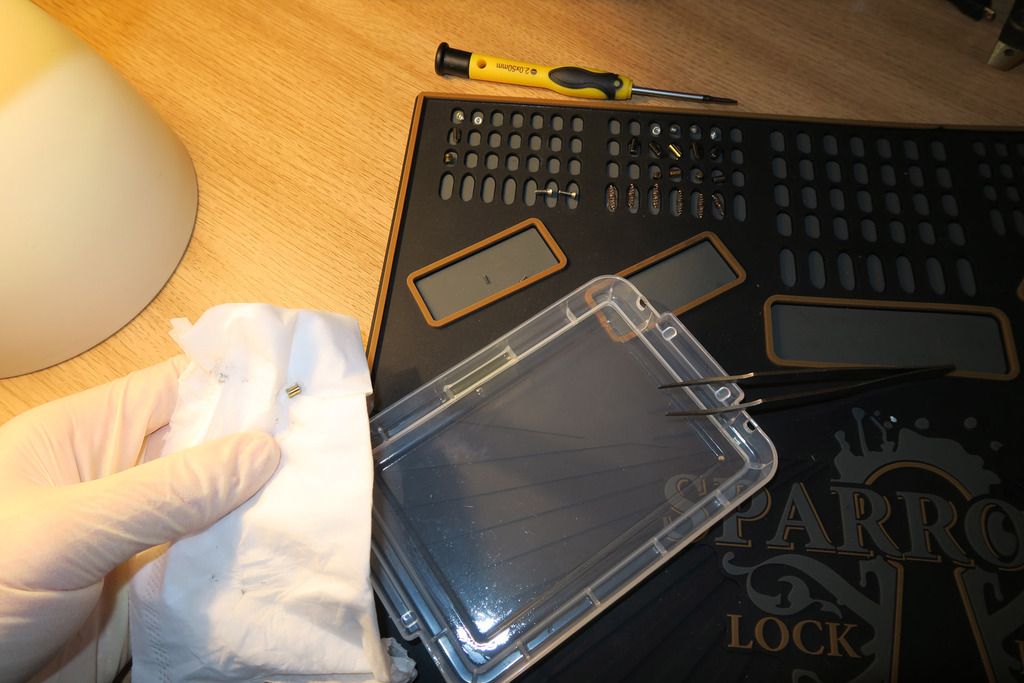

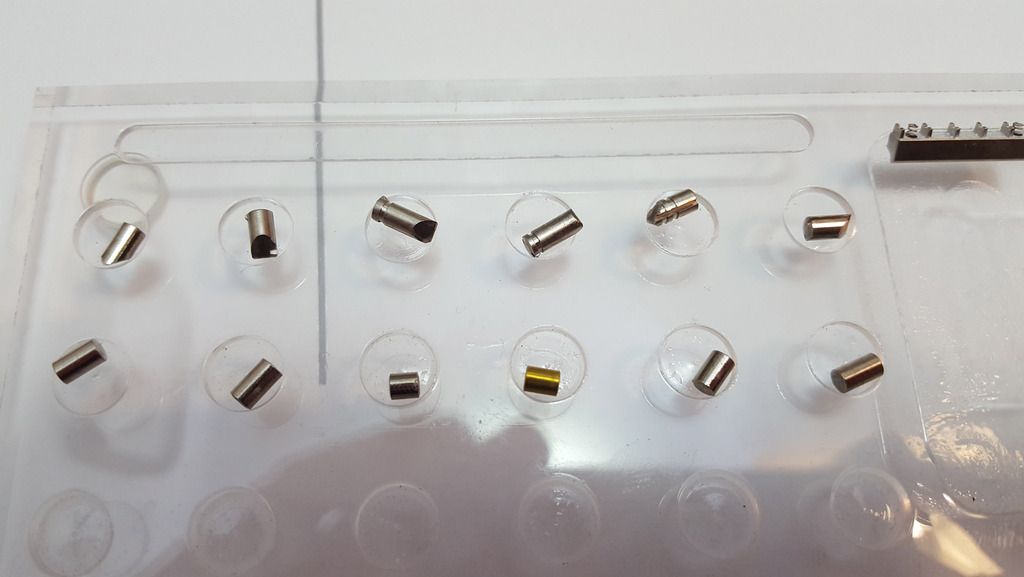

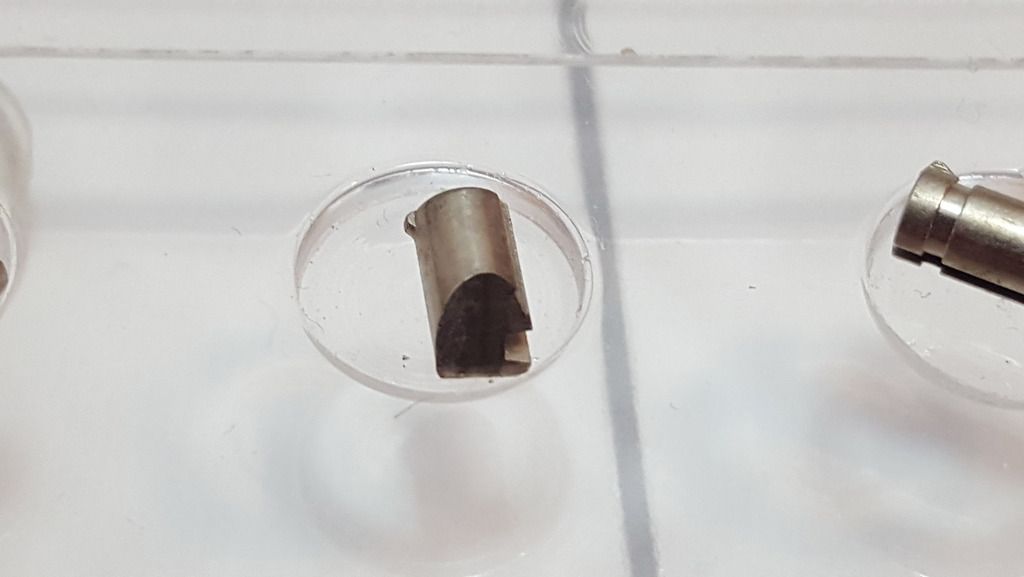

Key pins stripped from the plug:

You can see the wedge-end on the pin that I was talking about – that will be rotated by, and sit flush in, the angled cut in the key. Sadly in this photoset I didn’t take a photo of that. You can also see some serrations – I assume to catch on the plug as an anti-picking measure (similar to a serrated pin), and the groove cut into the side for the sidebar to fit into.

Pin from the end, showing the sidebar cut, a “false gate” higher up (to fool picking/rotating attempts), and the keep-position nub on the opposite side and end of the pin:

A look down inside the hollow cylinder with the springs sticking out of the bible:

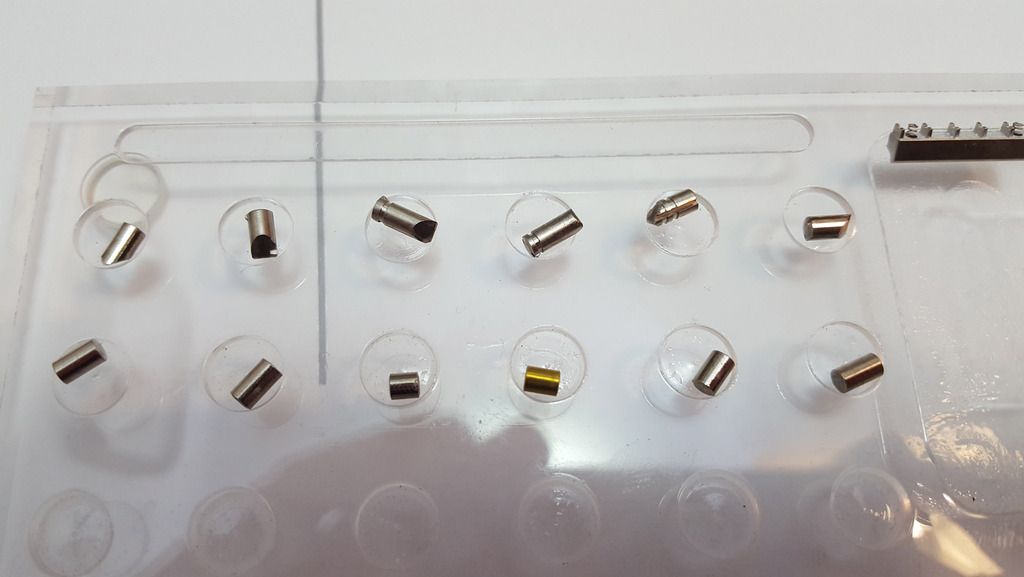

All key and driver pins. Interestingly, the drivers are all standard pins:

All the various lock bits and bobs:

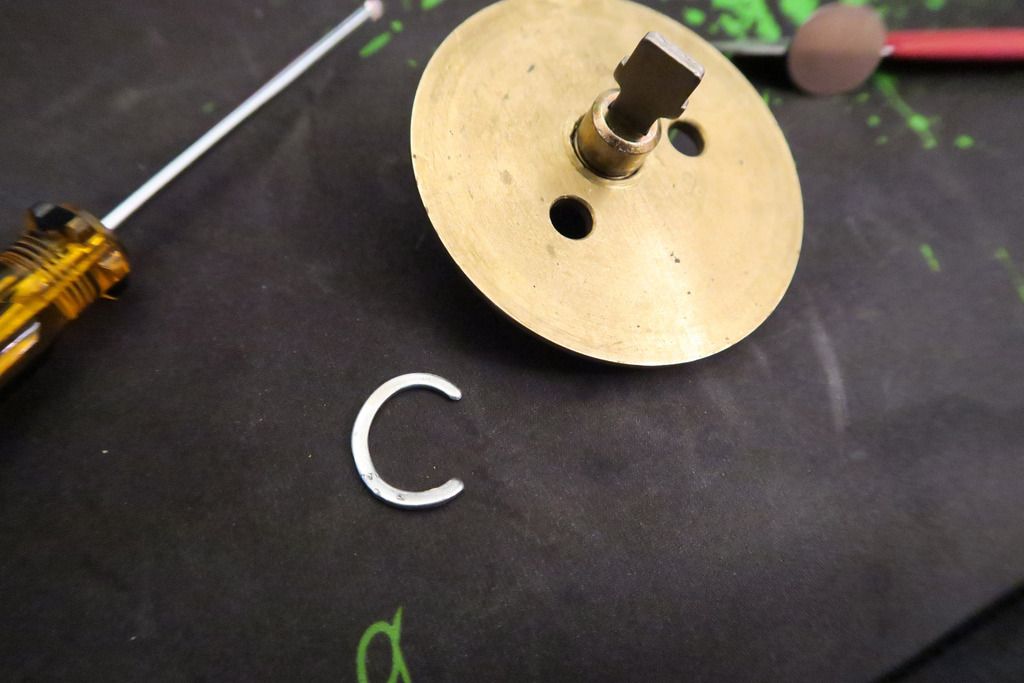

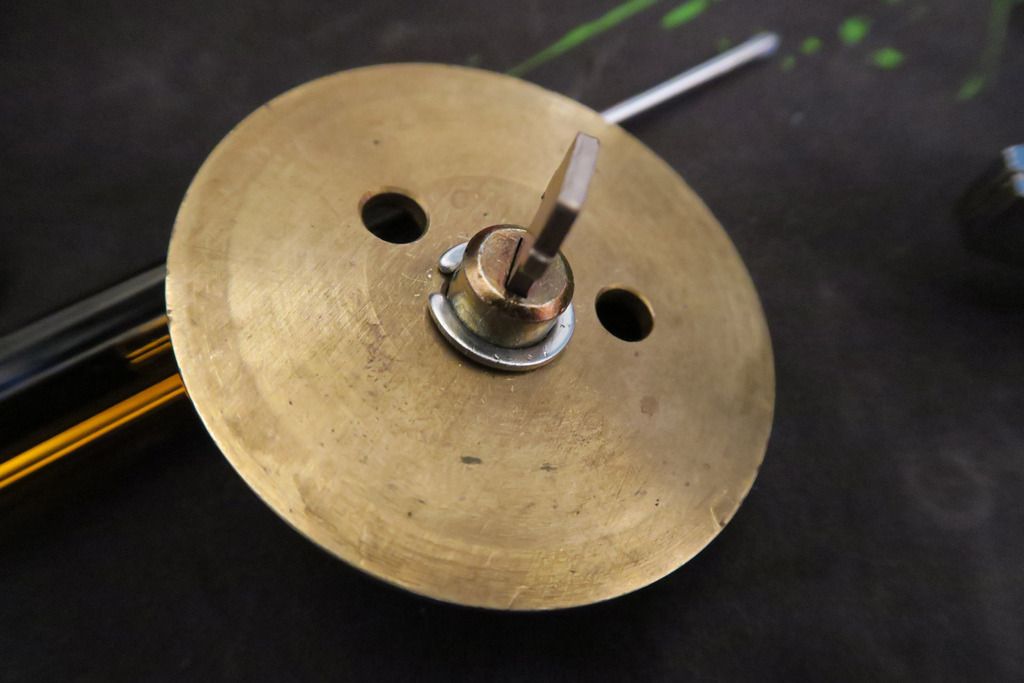

Fitting the anti-drill plate and actuator back onto the re-assembled cylinder:

Slot it back into the lock, with the notch in the top of the actuator facing the gap in the body (important, as the other half of the body needs to slide in there!):

Re-assembled:

And there we go! I hope you enjoyed this little look at the Sargent & Greenleaf 833!